Building the future: Ruger 10/22 case built with advanced 3D printing

The Ruger 10/22 is one of the most popular and versatile .22 LR rifles ever produced. Its decades-long success stems from inherent reliability, simple disassembly, and a vast aftermarket ecosystem. While countless stock and chassis options exist, the rise of easy-to-use 3D printing technology has opened up a new frontier: the ability to design and manufacture your own custom The chassis is customized precisely to your needs. It’s not just hobby tinkering; leverage Professional grade Additive manufacturing transformed this project, unlocking levels of complexity, weight reduction and ergonomic personalization currently unachievable with traditional methods.

Why consider 3D printing your 10/22 chassis?

- symptom Unparalleled customization: Forget about adapting to an off-the-shelf chassis. 3D allows you to design precise grip angles, pull lengths, cheek weld heights, M-LOK/Picatinny rail placement or unique aesthetic finishes, you desire. Left-handed shooter? Design a perfectly asymmetrical layout.

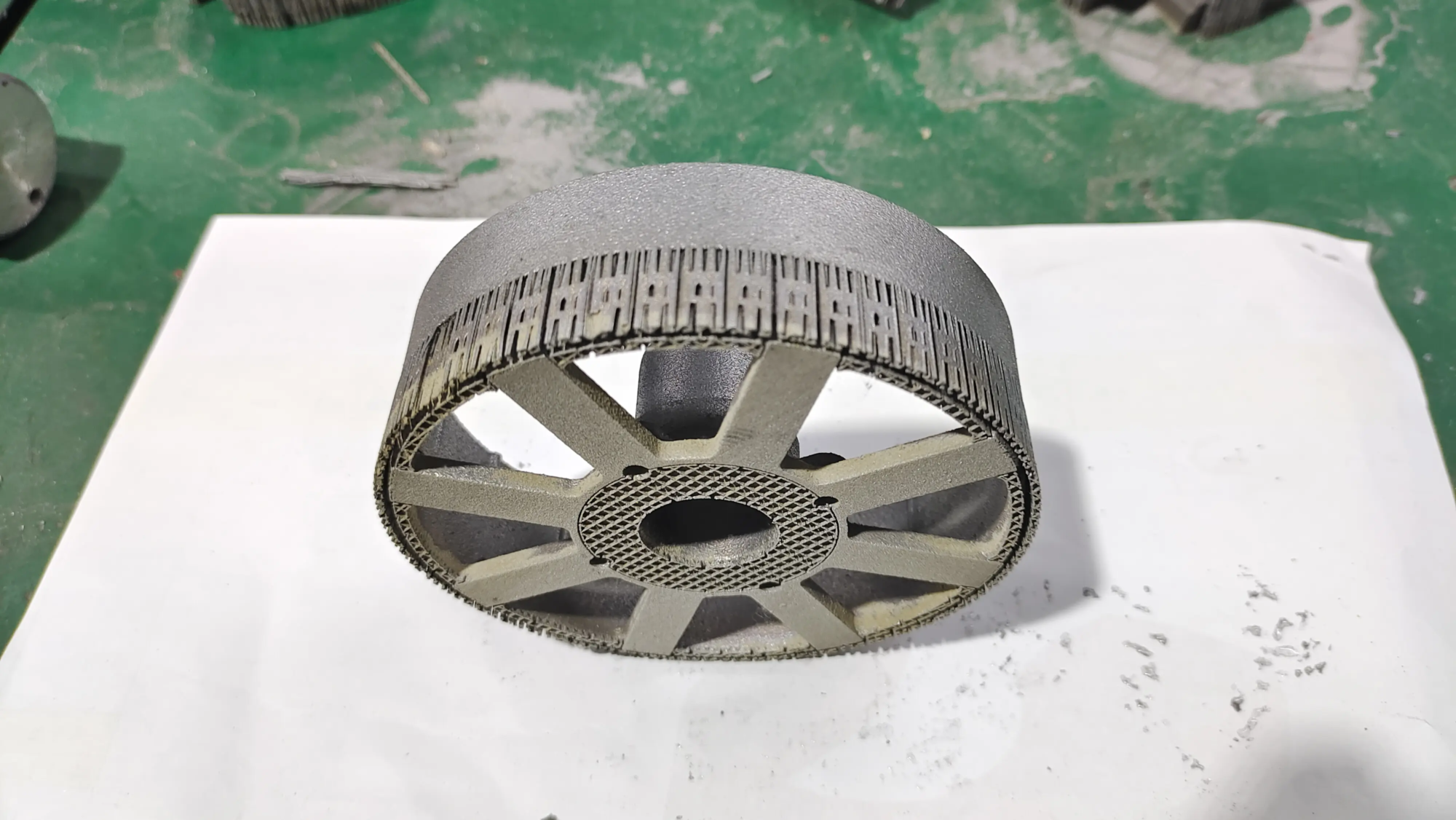

- Weight optimization: Advanced generative design principles can be applied at the CAD stage to strategically place material only where stress dictates, resulting in extremely lightweight yet rigid structures not possible with traditional milling.

- Comprehensive features: Features like QD sling mounts, buffer tube guides or unique magazine releases are built directly into the one-piece chassis design during the print process.

- Rapid prototyping and iteration: Design, print prototypes, test fit and functionality, make CAD adjustments and reprint in hours or days – significantly speeding up development cycles compared to CNC machining.

Key considerations: safety, materials and design

Manufacturing gun parts comes with a huge amount of responsibility. Safety is paramount.

- Material selection is crucial: The chassis can withstand recoil, magnetic changes, impacts and mounting stresses. For demanding firearms applications, engineering grade Metal 3D printing is often essential. Common thermoplastics, especially plastics (PLA, PETG, ABS) often lack the required strength, creep resistance and long-term temperature stability.

- Enter advanced metal additive manufacturing: Technology such as Selective Laser Melting (SLM) Excellent performance here. SLM uses powerful lasers to fuse fine metal powders layer by layer, producing nearly full-density parts with mechanical properties comparable to forged materials. At GreatLight, experienced engineers precisely optimize laser parameters, scan paths and metal support structures, e.g. AlSi10Mg (aluminum alloy), titanium alloy (Ti6Al4V) or maraging steelchosen for its strength-to-weight ratio, toughness, HRA and fatigue resistance – ideal for chassis integrity.

- Design integrity: A successful chassis CAD model requires careful FEA (finite element analysis) simulation to predict stress concentrations under load (recoil pulses, gun drop scenarios). Stresses must be kept away from critical interfaces such as receiver mounting points and buffer tube attachments. Wall thickness, internal ribs and topology optimization are key factors managed by expert designers. DIY designs without rigorous analysis carry significant risks.

- Fit and tolerance control: The chassis must fit seamlessly with the Ruger 10/22 receiver barrel assembly and other components such as AR-style buffer tubes or stocks. Metal 3D printing, especially SLM, offers exceptional dimensional accuracy and resolution. GreatLight’s expert post-processing – including CNC machining of critical interfaces (reaming buffer tube threads, rail groove finishing) and precision heat treatment (stress relief, aging) – ensures critical tolerances (usually mating parts) are maintained within +/- 0.05mm or betterguaranteeing a perfect, tilt-free fit.

- legality: Understand and strictly comply with all local, state and federal regulations regarding firearms and firearm parts before proceeding any Projects involving 3D printing of gun parts. Many jurisdictions impose specific restrictions on certain components or require serialization.

The road to professionalism: Using GreatLight to create a 3D printed chassis

While desktop FDM printers have popularized 3D printing, the Ruger chassis exemplifies applications that require an industrial-grade solution. Here’s why working with an expert like GreatLight can transform your process:

- Advanced SLM features: GreatLight features a next generation laser powder bed fusion system. High laser power, precision optics and advanced chamber atmospheres ensure the highest material integrity, minimal porosity and superior mechanical properties from skeletal aluminum to demanding titanium.

- Materials expertise: In addition to printing, GreatLight provides recommendations for optimal material selection based on your design priorities (maximum weight reduction, ultimate strength, corrosion resistance). The use of certified metal powders ensures consistent quality.

- Engineering partners: GreatLight is more than just a printer operator. Their engineers work with customers on Design for Additive Manufacturing (DfAM). This includes stress analysis support, topology optimization, identifying manufacturable geometries, and recommending customizations to improve structural efficiency and print reliability while reducing costs.

- Post-integration processing: Original prints often require finishing. GreatLight provides seamless One stop solution:

- CNC machining: Precision milling/turning of critical mating surfaces (receiving bed, buffer tube threads) and guideway interfaces.

- Heat treatment: Customized thermal cycling (solution annealing, aging) to achieve peak material strength and eliminate residual stresses.

- Surface treatment: Options include smoothing techniques (vapor smoothing for polymers, abrasive flow machining/media blasting/vibration polishing for metals), aesthetic bead blasting or special coatings (anodizing of aluminum, Parkerizing or Cerakote for corrosion protection).

- Speed and Accuracy Prototyping: Need a functional prototype quickly? Gretel focuses on rapid prototyping Leverage streamlined processes and optimized nesting/printing strategies to deliver custom metal parts faster than traditional machining, often within days.

- Scalability: Whether it’s a one-off prototype perfecting your design or low-volume production, GreatLight offers flexible manufacturing solutions.