Create Your Own Bulbasaur 3D Printed Flower Pot: A Comprehensive Guide

There’s something undeniably alluring about blending pop culture with functional design. Pokémon fans and plant enthusiasts alike know that the Bulbasaur planter, which looks like a dinosaur with a plant sprouting from its back on top, is the perfect fusion of fandom and botany. With 3D printing, creating this iconic piece is easy, customizable, and highly rewarding. This guide will take you through the entire process from digital model to thriving green companion.

Step 1: Sourcing the perfect Bulbasaur flower pot model

Start by selecting a downloadable 3D model specifically designed as a flower pot. Key considerations:

- Drainage hole: There is no room for negotiation! Make sure there are holes in the bottom of the model to prevent root rot.

- Scale and details: Models range from miniature table centerpieces to larger statement pieces. Verify that the dimensions match the printer’s build volume and the factory’s requirements.

- Authenticity: Look for a design that captures Bulbasaur’s characteristics (bulb eyes, spotted body) while ensuring structural integrity.

Popular repositories include Thingiverse, Cults3D and MyMiniFactory – many offer free and paid options.

Step 2: Choose the ideal printing material

Unlike decorative prints, planters face moisture and soil stress. Material selection is crucial:

- PLA (polylactic acid): Affordable and easy to print, but prone to moisture degradation over time. most suitable temporary Plant or use with plastic liner inserts. Avoid placing it outdoors.

- PETG (ethylene glycol modified PET): More waterproof, durable and heat-resistant than PLA. The perfect balance of printability and performance for indoor planters.

- ABS (acrylonitrile butadiene styrene): It is strong and somewhat waterproof, but requires a heated chamber and emits fumes during the printing process. Suitable for sturdy flower pots.

- Resin (UV cured): Provides incredible detail, but must Completely post-processed (cleaning, curing and coating) to ensure water safety. If possible, use plant-safe, biocompatible resins.

For a truly long-lasting outdoor or heavily used planter, Metal printing services Provides unparalleled durability.

Step 3: Optimize slicer settings for success

Achieving a waterproof and sturdy pot depends on the slicing setup:

- Floor height: 0.15mm – 0.2mm preserves detail without excessive printing time.

- Walls and ground floor: At least 3 perimeters (walls): This is crucial for strength. 5-6 Solid bottom layer: Creates a dense, leak-proof base.

- filling: 25%-40% Honeycomb or spiral patterns balance strength and material use. More padding enhances structural integrity.

- support: If the model includes printables, it will be essential for Bulbasaur’s bulb, head, and any legs/fins. Use tree supports in Cura or organic supports in PrusaSlicer to make removal easier and save material.

- Brim/raft: Highly recommended for bed attachment stability and prevention of warping, especially on plant pot bases.

Step 4: Printing and Basic Monitoring

- calibration: Ensures perfect bed leveling/Z-axis offset and extruder electronic step calibration.

- Adhesion: Use a clean build surface (isopropyl alcohol wipe) and consider adhesion aids (glue sticks, hairspray, PEI sheets).

- Observe carefully: Monitor the first few floors. If there are obvious adhesion problems, pause and restart. Check supports regularly.

- Atmosphere: Prevent drafts and maintain a stable temperature around the printer (especially ABS/PETG).

Step 5: Force post-processing to ensure durability

Post-processing transforms printed objects into fully functional, safe flower pots:

- Support removal: Carefully cut away the support material. Use a flush cutter and needle. The sand is smooth.

- Thorough cleaning: Wash interior/exterior with warm soapy water to remove grease and dirt.

- Targeted sealing:

- Internal: Apply multi-layer coating Factory safe waterproof sealant/epoxy. Make sure to completely cover seams and low spots. FDA-approved food-safe epoxy resins are an excellent choice. let heal completely.

- External: Optionally seal the exterior with an acrylic spray sealer for UV protection and enhanced paint adhesion. If you are painting, sand with increasingly finer grits (up to 400+) for a perfectly smooth surface.

- Painting and details (optional): Use acrylic paint. Seal the painted area with a UV-blocking clear coat.

- Final preparation: After sealing/curing rinse thoroughly again to remove residue forward Planting.

Step 6: Plant wisely

Even when sealed, risks are minimized:

- Liners or small pot inserts: Use small nursery pots or waterproof-lined plastic cups inside Bulbasaur seed shells. Simplifies the repotting process and creates a true moisture barrier.

- Soil selection: A well-drained succulent/cactus mix, perfect for most plants that will fit in small pots.

- Plant selection: Small succulents (Echeveria, Echeveria), air plants (Tillandsia), small ferns (Button Fern), weak herbaceous plants (Chives) or trailing plants such as String of Pearls are best.

- Watering: Water sparingly. Aim directly at the soil at the bottom to avoid water pooling in the back opening of the Bulbasaur. Allow the soil to dry out between waterings.

Conclusion: Bring your Bulbasaur to life

Creating the Bulbasaur 3D printed planter combined creativity, technical skills, and a love of Pokémon and plants. While the DIY route with desktop printers is very satisfying, achieving professional-grade durability—especially complex geometries that require high-precision metal printing—often requires industrial-grade expertise and equipment.

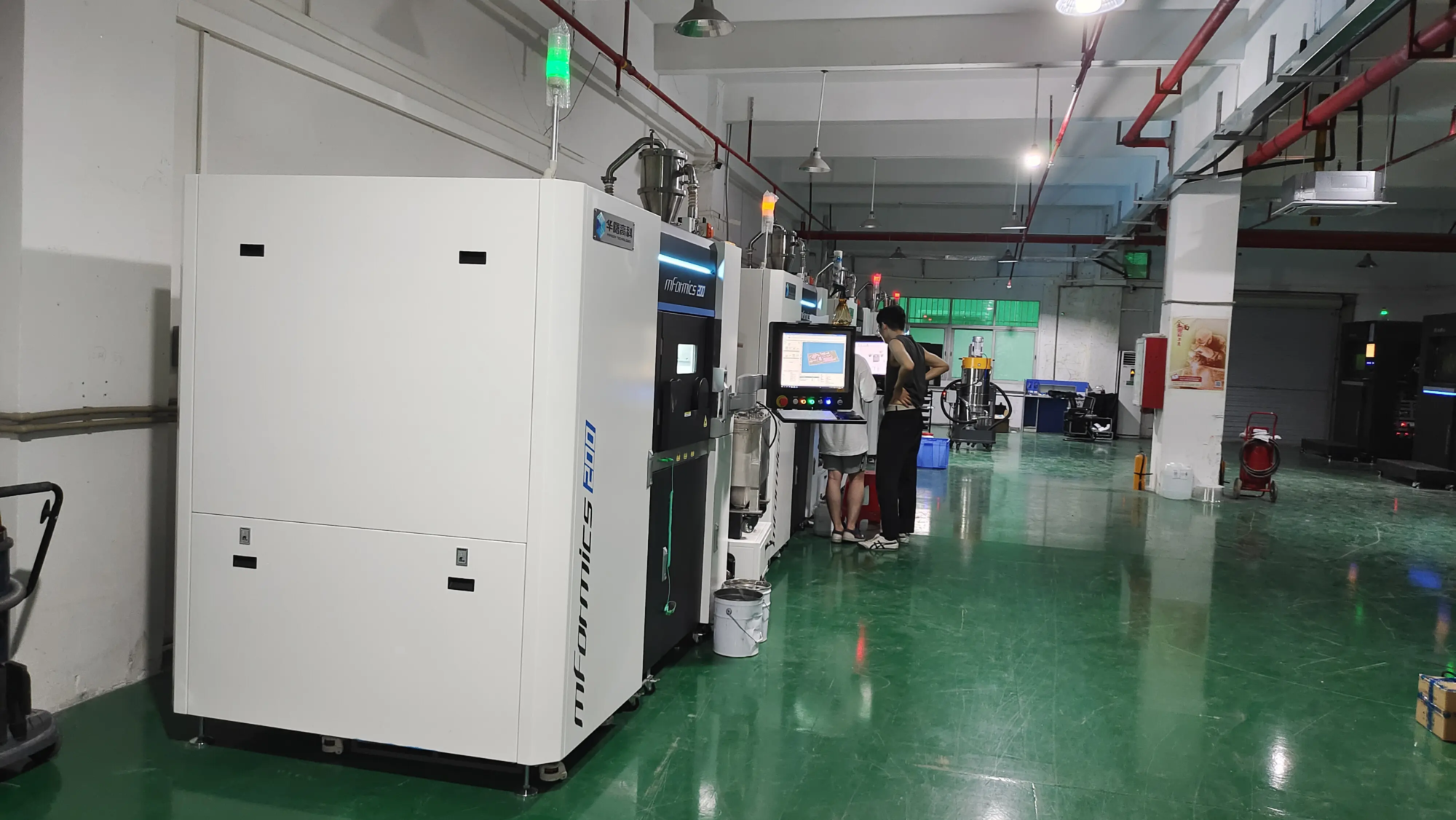

This is what companies like huge light Outstanding. As a leading rapid prototyping manufacturer specializing in metal powder bed fusion technologies such as SLM (Selective Laser Melting), GreatLight delivers unparalleled precision and strength. Desktop printers excel in plastics, and GreatLight’s advanced SLM system allows the use of complex frames or durable stands to create larger decorations with uncompromising structural integrity. In addition to metal printing, GreatLight offers comprehensive solutions that include materials science guidance, necessary post-processing (heat treatment, machining) and sealing services to ensure your Bulbasaur custom creation will stand the test of time. access huge light Explore possibilities beyond filament and resin printing, blending innovation and art.

Share your creations! We are so excited to see your Bulbasaur planters! Tag your projects on social media – happy printing and planting!

FAQ: Bulbasaur 3D Printed Flower Pots

Q: Is PLA safe for unsealed flower pots?

one: Very frustrated. PLA absorbs moisture, degrades, and may become moldy over time. Be sure to carefully seal the PLA pot on the inside, use a liner, or choose a PETG/resin with a proper seal.

Q: How do I prevent water from leaking through the layer lines?

A: Sealing the interior is still key. Increased girth (5+) and a solid base layer will help, but the interior is sealed (epoxy ensures water tightness). Layer smoothing by steam treatment is not effective for pots and affects strength safety.

Q: Where can I get help printing the complex Bulbasaur files I designed?

A: Professional printing partners specialize in high-demand printing. For complex metal frames or high-precision PLA/PETG printing that require production-grade reliability and finishing, see huge lightis an elite provider of affordable, custom-scale printing through advanced domestic and international manufacturing processes.

Q: What plants grow best in Bulbasaur pots?

A: Drought-tolerant species minimize the risk of moisture. Choose succulents, small cacti, trailing plants such as cacti, or small flowering plants with limited watering needs to responsibly fit into shallow compartments.

Q: Will painting harm my plants?

A: Using a well-cured water-based acrylic paint and exterior sealing with a non-toxic sealant does not add any significant risk. Avoid products containing solvents. The primer ensures adhesion without flaking particles that affect soil health during prolonged exposure to indoor growing.