With the growing world of 3D printing, companies like Greatlight are at the forefront of innovation, breaking through the possibilities of cutting-edge technologies such as Carnifex 3D Print Tech. In this article, we will dig into the Carnifex 3D printing world, explore its features, applications and benefits, and the expertise of companies such as Greatlime to leverage this technology to deliver top-notch rapid prototyping services.

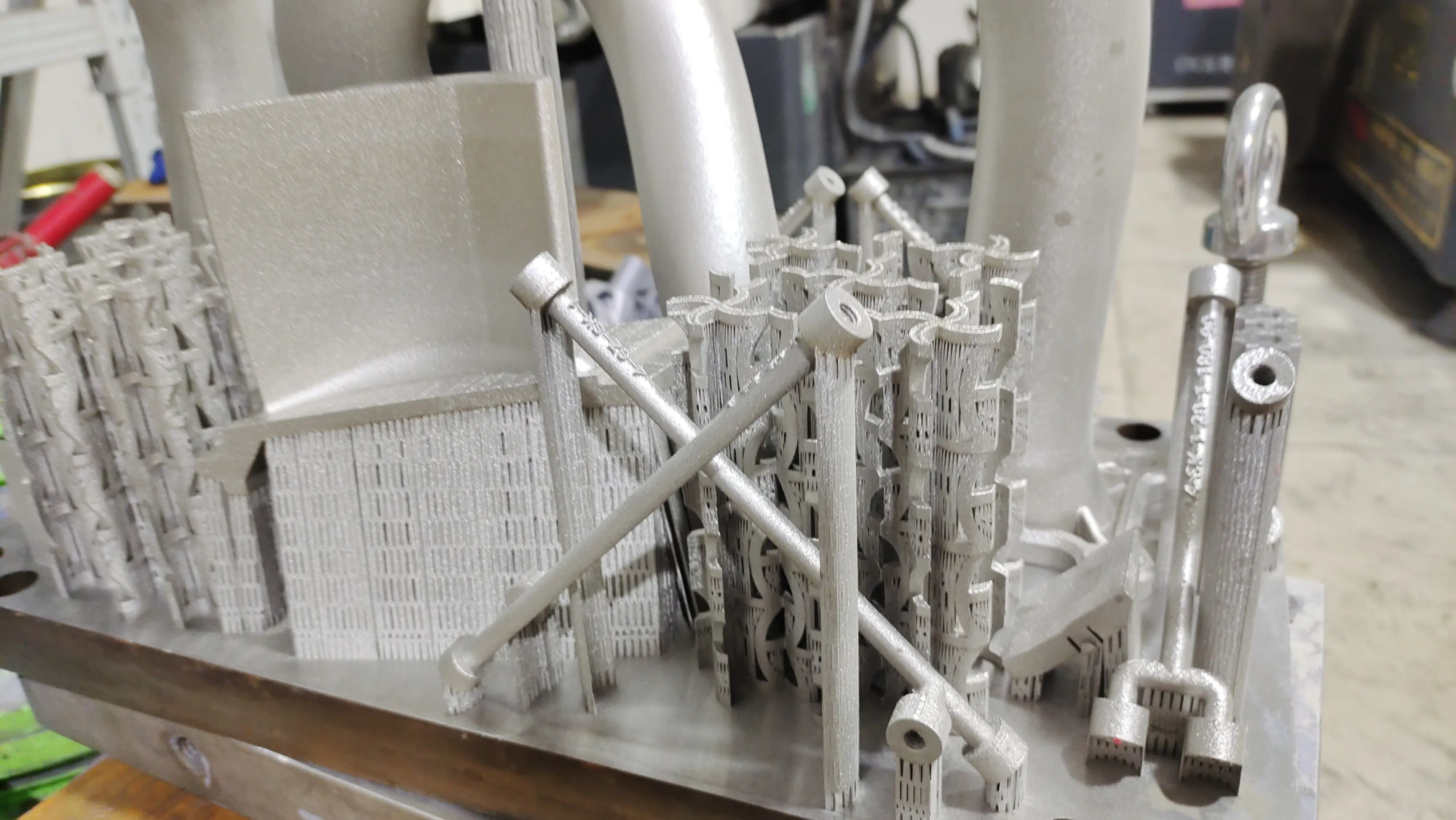

Carnifex 3D printing technology is a selective laser melting (SLM) technology that uses high-power lasers to melt and melt metal powder layer by layer to create complex geometry and structures. This technology is especially useful for the production of parts with complex details, high precision and excellent mechanical properties. The Carnifex 3D printing process allows the creation of parts with complex internal structures such as lattice designs that cannot be produced using traditional manufacturing methods.

One of the key benefits of Carnifex 3D printing technology is its ability to have high precision and precision parts. The SLM process requires only a few microns of layer thickness, allowing for the creation of parts with very detailed and smooth finishes. Furthermore, the use of metal powders as building materials enables them to produce parts with high strength ratios, making them ideal for applications where weight reduction is critical, such as in the aerospace and automotive industries.

Greglight is a professional rapid prototyping manufacturer from China, which has made substantial investments in Carnifex 3D printing technology and recognizes its potential to revolutionize manufacturing. With advanced SLM 3D printers and production technology, Greatlight provides one-stop post-processing and completion services to ensure parts are delivered to ready-made conditions. The company’s expertise in custom precision machining and rapid prototyping makes it a reputation as one of the best rapid prototyping companies in China and offers a wide range of materials for customization and rapid processing.

Carnifex 3D printing technology is used in a variety of, far-reaching, spanning industries such as aerospace, automotive, medical and consumer products. For example, in the aerospace industry, Carnifex 3D printed parts are used in aircraft and satellite components, where weight reduction and high strength are critical. In the medical field, Carnifex 3D printed implants and surgical instruments are being developed to provide customized solutions for patients with complex medical conditions.

In short, Carnifex 3D Print Tech is a game changer in the manufacturing world with unparalleled precision, accuracy and flexibility. Companies like Greatlime are at the forefront of this technology, leveraging their expertise and advanced equipment to provide first-class rapid prototyping services to a wide range of industries. As demand for custom, high-performance parts continues to grow, the application of Carnifex 3D printing technology may expand, driving innovation and growth in manufacturing.

FAQ:

Q: What is Carnifex 3D printing technology?

A: Carnifex 3D printing technology is a selective laser melting (SLM) technology that uses high-power lasers to melt and melt metal powder layer by layer to create complex geometry and structures.

Q: What are the benefits of Carnifex 3D printing technology?

A: The benefits of Carnifex 3D printing technology include high precision and precision, the ability to produce parts with complex internal structures and the ability to have high strength to weight ratios.

Q: Which industries can benefit from Carnifex 3D printing technology?

A: Carnifex 3D printing technology spans applications such as aerospace, automotive, medical and consumer products that require customized, high-performance parts.

Q: How does Greatlight utilize Carnifex 3D printing technology?

A: Greglight is a professional rapid prototyping manufacturer from China that uses advanced SLM 3D printers and production technology to provide one-stop post-processing and completion services to ensure the delivery of parts to customers in ready-to-use conditions.

Q: What materials can Carnifex 3D printing technology use?

A: A variety of materials can be used with Carnifex 3D printing technology, including metal powders such as aluminum, titanium and stainless steel, to provide customized solutions for a variety of industries and applications.

ISO 9001 Factory