Cerakote for 3D printing: improving functionality and aesthetics beyond the print bed

The world of 3D printing has exploded, allowing creators to bring complex designs to life using materials once unimaginable through additive manufacturing. However, achieving a true professional-grade finish, exceptional durability or specific functional properties on thermoplastic prints remains a challenge. Cerakote is a high-performance ceramic-based coating commonly associated with firearms and aerospace. Its application on 3D printed parts is revolutionizing the way we think about post-processing, providing unparalleled advantages for demanding applications. This guide takes an in-depth look at Cerakote for 3D printing, exploring its potential, processes, considerations, and why it might be your ultimate finishing solution.

Beyond Painting: Understanding Cerakote

Cerakote is more than paint; It is a thermoset ceramic polymer composite coating applied as a film (typically 0.001 – 0.002 inches). It undergoes a curing process under heat, forming an extremely hard chemically bonded layer. What makes it different is:

- Excellent durability: Cerakote offers excellent resistance to abrasion, scratches, impact and harsh chemicals (solvents, fuels, acids). It performs significantly better than standard paint or powder coatings.

- Thermal stability: Able to withstand sustained high temperatures (certain series are rated up to 1000°F/538°C), making them suitable for use in engine compartments or near heat sources.

- UV resistance: Highly resistant to fading, chalking or sunlight degradation.

- True barrier protection: Creates an impermeable layer that protects the plastic underneath from moisture, solvents and environmental degradation.

- Multifunctional cosmetics: There are hundreds of colors and finishes to choose from (gloss, satin, matte, metallic) as well as specialty options like fluorescent and camouflage patterns (although these usually require a specific primer).

- Electrical characteristics: Certain Cerakote formulations are engineered to provide electrical insulation or conductivity.

Why choose Cerakote for 3D printing?

Standard printed parts often lack the surface ruggedness required for outdoor functional use, mechanical assembly, or environments where aesthetics are critical. Cerakote bridges this gap:

- Conversion function: Create tough-as-nails parts for gears, brackets, housings exposed to the elements, automotive parts, drone parts and tools that resist wear and tear.

- Improve aesthetics: Achieve a flawless, high-end, professional look not possible with original printing. Colors stay vibrant.

- Chemical resistance: Protects prints from automotive fluids, cleaners, oils – critical where standard plastics can deteriorate.

- Weatherproof: Seals prints to prevent moisture ingress and prevent warping, swelling or UV degradation.

- Extend wear life: Reduce friction and wear on moving parts or handling surfaces.

- Professional attributes: Add electrical insulation, electrostatic dissipation (ESD), or specific thermal properties.

Cerakote Craft: More Than Spray and Pray

Successfully applying Cerakote to 3D printing requires careful preparation and precise execution:

- Key Cleaning: eliminate all Oils, contaminants, fingerprints and release agents left over from printing or processing. Use a solvent such as acetone or a special degreaser. Failure here guarantees coating failure.

- Preparing for printing:

- Polishing: Basic! Start sanding roughly (for example, 180 grit) to smooth out the layer lines and key the surface. Progress through finer grits (240, 320, and even 400+ for glossy finishes). Remove all sanding dust (compressed air + tack cloth). NOTE: Cerakote is thinner; it will not fill deep print lines. The surface treatment determines the final smoothness.

- Post-processing options: Techniques such as vapor smoothing (for ABS, ASA, certain polycarbonates/blends), sandblasting (softer media like plastic or soda), or epoxy primer/filling can greatly reduce sanding work and improve substrate smoothness.

- Warm up: Generally recommended for plastics. A brief bake (below the material’s Tg) helps eliminate residual moisture/gases that may cause outgassing (bubbles) during curing.

- Use adhesion promoters/catalysts: Some Cerakote formulations require custom catalysts to be added to the coating. Crucially, surfaces such as PETG, nylon and polypropylene are known to require a compatible adhesion promoter sprayed as a thin base layer. For many common functional filaments, this step is non-negotiable.

- Spray application: Using Cerakote requires specialized HVLP (High Volume Low Pressure) spray equipment and skills. Achieve thin and uniform "mist coat" Next is a slightly heavier one "Flow coating" No bleeding or sagging. Drug tolerance is critical.

- Flash time: Brief air drying (20-30 minutes) before curing allows the solvent to evaporate.

- Maintenance: The most critical step. Parts are baked at a specific temperature (usually 250-300°F/121-149°C) in a dedicated temperature-controlled curing oven for precisely timed cycles. This triggers a thermoset reaction, forming covalent bonds. Microwaves, heat guns, hot water, or low-temperature baking are unreliable alternatives. Precise thermal control is necessary.

Material Compatibility: Know Your Filament

Not all filaments are suitable for Cerakote! Successful application requires residual cleaners, accelerator solvents, and crucially, cure temperatures No obvious deformation.

- Ideal candidate:

- PEEK, PEKK, PPSU: High-performance thermoplastic designed to withstand heat; a perfect match if properly prepared.

- ABS: Excellent compatibility with curing temperatures (~250°F). Responds well to steam smoothing before coating.

- ASA: Similar to ABS, excellent UV and heat resistance make it the first choice.

- Nylon (PA66, PA12): Requires careful surface preparation and specific Adhesion promoter. Lower Tg PA filaments can become hazardous near curing temperatures.

- Polycarbonate (PC): can work but need Anneal first (~250-275°F) to relieve stress forward coating/curing, otherwise the risk of warping/cracking is high.

- Questionable/marginal candidates:

- Polyethylene glycol: major challenges. PETG releases ammonia vapor above ~170°F, which can interfere with Cerakote cure chemistry. The result is fish eyes, wrinkles, and poor adhesion. Traditionally avoided. Some newer Cerakote chemistries and complex pretreatment regimens possible Success has been limited but unreliable. Alternative coatings such as epoxy paint are generally safer for PETG.

- Thermoplastic polyurethane/thermoplastic elastomer: Highly flexible substrates may cause the rigid Cerakote layer to crack. Generally not recommended unless extremely high stiffness is required for small cross-sections.

- People’s Liberation Army: Medium risk. The semi-crystalline nature means Tg varies widely (~140-180°F). May experience unexpected softening/sag at curing temperatures. Risk of warpage. Silver PLA releases plasticizers that affect adhesion.

- recommend: Always test-cure sacrificial prints made from specific batches of filament before submitting critical parts. PC parts must be annealed before Cerakote.

Cosmetics: Managing Expectations

Cerakote provides tough terrainnot magical smoothness. While sandblasting or extensive sanding (400+ grit) prior to coating will produce a smoother finish, Cerakote itself Will reflect the underlying surface texture:

- Matte finish: Forgiving; best hides small imperfections.

- Satin finish: Balanced appearance.

- Gloss finish: Extremely intolerant. An extremely smooth pre-coated surface is required to achieve true shine. A mirror shine will only be found on highly prepared surfaces.

Is DIY practical? Consider professional services

Achieving a durable, functional Cerakote finish on print requires significant investment and expertise:

- HVLP spray equipment: Essential (around $500+ for a reliable setup).

- Special powder oven: Precise temperature control is critical (~$1000+).

- Controlled environment: Dust-free ventilation is essential.

- Chemicals: Adhesion promoters, catalysts, cleaners (approximately $75 to over $150).

- Skill: Requires mastery of spraying techniques and process discipline.

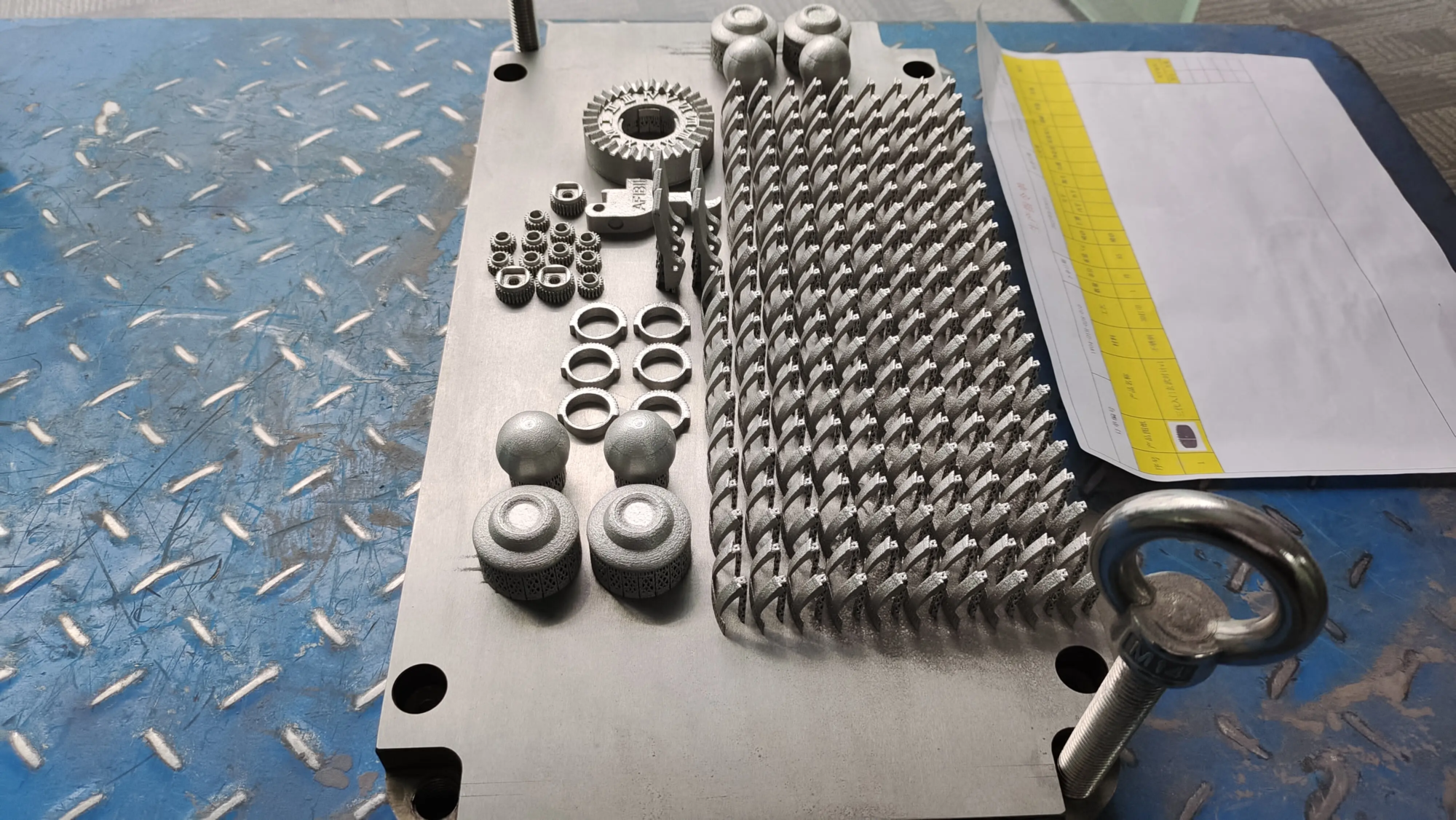

For most hobbyists or single projects, Professional Cerakote application services provide superior quality, reliability and safety. company likes huge lightAs experts in advanced manufacturing and rigorous post-processing, we are uniquely positioned to effectively deliver specialized services on complex metal SLM prints and functional thermoplastics. Our state-of-the-art facilities ensure the precise cleaning, preparation, spraying and temperature-controlled curing Cerakote requires to run reliably on demanding 3D printed components.

in conclusion

Cerakote represents a paradigm shift in functional surface finishing capabilities for 3D printed parts. It goes beyond the limitations of standard paint and plastic properties to deliver superior durability, chemical resistance, thermal stability and professional aesthetics. While the process requires careful preparation, especially in terms of material compatibility and curing, the rewards for functional prototypes, end-use parts, or components that require resiliency are huge. By understanding the limitations of filament (particularly PETG/polypropylene risks and the annealing requirements of PC), investing in appropriate surface preparation, and leveraging professional-grade application technology (either DIY or outsourced with significant investment), Cerakote unlocks new performance and reliability for additive manufacturing. If your application requires unparalleled protection and longevity beyond the inherent limitations of printed polymers, Cerakote is more than just an option; it’s often the ultimate finishing solution.

FAQ: Cerakote on 3D Printed Parts

Q1: Can I print with Cerakote PLA?

A1: It is risky and generally not recommended. PLA (especially standard formulations) has a low glass transition temperature (Tg) and begins to soften near the lowest Cerakote cure temperature (~250°F/121°C). Warping and sagging are common. Semi-flexible varieties release plasticizer. If you try, use high temperature annealed PLA (be careful!) and rigorously test the sacrificial parts. High-temperature resins such as ABS, ASA, nylon, and PEEK are safer choices.

Q2: Why is PETG a problem for Cerakote?

A2: PETG releases ammonia vapor when heated above approximately 170°F (77°C). Ammonia directly interferes with Cerakote’s curing chemistry, often causing bonding failure and bubbling ("fish eye"), wrinkles or uncured soft spots. Despite the existence of newer experimental techniques, PETG remains unreliable for Cerakote. Choose an epoxy-based paint.

Q3: Can Cerakote hide layer lines?

A3: Not significant. Cerakote is very thin. While it can somewhat mask slight texture when applied to properly prepared (smoothed/sanded/filled) parts, it mostly adheres to the existing terrain. Pre-coating smoothing techniques (sanding, steam smoothing, epoxy primer) are critical to reducing layer lines. Glossy Cerakote will appear shiny on rough surfaces and There is texture.

Question 4: What is the lifespan of Cerakote on printed parts?

A4: When Cerakote is properly applied to the appropriate filament, its service life will be very long. Its chemical bonds, hardness and UV resistance protect it from degradation better than paint. If the underlying plastic does not degrade (use UV-resistant filaments like ASA or ASA-coated primer), you can expect years or even decades of use with normal weathering.

Q5: Can I use a heat gun or a regular oven to make Cerakote parts?

A5: Unreliable. Professional results require precise temperature control within a specific range (±10°F tolerance) throughout the cure cycle. Home ovens have inaccurate thermostats and hot spots; heat guns don’t heat evenly. Common results are outgassing, soft spots, inconsistent color, or bond failure. A dedicated powder coating oven is required.

Q6: Will Cerakote increase the thickness? Will the size change?

A6: Cerakote adds a minimal layer (0.