Embrace creativity: Your comprehensive beginner journey with Craftbot 3D printer

Enter the world of 3D printing that unlocks the universe of creativity, prototypes and DIY potential. For beginners looking for a reliable, user-friendly entry point, the CraftBot 3D printer is an outstanding choice. Known for its powerful build, intuitive operation and consistent results, it enables manufacturers to confidently turn digital dreams into physical reality. This guide will unveil your Craftbot journey, covering setup, operations, troubleshooting, and best practices.

Why are crafts? The foundation for success

CraftBot prioritizes accessibility without compromising quality. Key features that make it ideal for beginners include:

- Sturdy build and closed design: Minimize vibration and noise while enhancing safety and temperature stability during printing.

- Automatic bed average (on most models): By ensuring the perfect nozzle to the bed distance for reliable adhesion, major obstacles for beginners are eliminated.

- User-friendly interface: Intuitive touch screen and simple menu navigation.

- Sturdy PEI spring steel printing bed: Provides excellent adhesives for PLA and PETG such as PLA and PETG and can be easily removed.

- Open filament compatibility: Use a range of 1.75mm wires to give you the flexibility to experiment.

Getting started: Setting up and calibration

- Unboxing and assembly: Carefully unpack all components. Most Craftbot models require the smallest components – attach the steel pipe brackets, flatten the build plates (if needed) and connect the cables. Follow the instructions included accurately.

- Location and security: Place the printer on a strong, horizontal surface away from the draft. Ensure good ventilation, especially for thin filaments such as ABS. As a general safety precaution, keep the fire extinguisher nearby.

- Initial settings and levels: Modern craft robots usually have automatic beds. Run this calibration process from the printer menu. If your model needs to be manually leveled, carefully follow the guided procedure, adjusting each corner screw until the nozzle gently holds a piece of paper at all points on the bed.

- Loading wire: Preheat the nozzle to the temperature recommended by the filament manufacturer (usually on the spool). Feed the end of the filament into the extruder inlet. use "Load wire" Work in the menu, push it to the hot end until the molten plastic flow is smooth.

Your first printing: From digital models to physical objects

- Find a model: It’s easy to get started! Use famous repositories such as Thingiverse, Printables or Cults3d. search "beginner" or "test" Calibrate cubic or keychain models.

- Slice – Digital Translator: Your printer needs instructions ("G code") Generated by slicing software.

- Crafts: Default software designed specifically for CraftBot provides optimized configuration files. This is a great place to start for beginners.

- Other options: Power users generally prefer Ultimaker Cura or Prusaslicer. Import the CraftBot printer configuration files and configuration settings.

- Key settings for beginners:

- Layer height: 0.2mm is a good balance of speed and detail.

- Fill density: 10-20% of the decorations, 20-50% of the functional parts that require strength.

- Printing speed: Start at 50-60mm/s. Be cautious in the future.

- Bed and nozzle temperature: Strictly follow the recommendations of filament manufacturers.

- Support and adhesion: Enable a "edge" For small parts or "raft" Tough sticky. Enable support for overhangs over 45 degrees.

- contour: Select a preset profile for your specific Craftbot model in the slicer.

- Send Print: Transfer the sliced G-code file (for example, via a USB drive, Wi-Fi or LAN, depending on your CraftBot model) to the printer. Start printing from the interface.

- Monitoring: Pay close attention to the first level – crucial! Make sure the filaments stick well throughout the pattern. Most printing problems are shown soon.

Best practices and troubleshooting common ics

- Filigree Care: Store PLA, PETG, TPU, etc. in a sealed container with desiccant to prevent moisture absorption (which can lead to fluffy, pop-up sound and poor printing quality). ABS/ASA requires a closed printer and a very stable environment.

- Bed adhesion failure:

- question: Warp or layers peel off from the bed.

- Solution: Clean the PEI plate thoroughly with >90% isopropanol. Re-upgrade the bed. Ensure the correct bed temperature. If necessary, use adhesive aids such as glue sticks or hair spray. Check the draft.

- Restoring worries: If the auto level seems inconsistent or the adhesion is spotty, even after cleaning, try running the auto level twice in a row. For manual levels, please do a paper test for a careful inspection by several points per corner.

- Clog nozzle:

- symptom: Insufficient sorting (thin or missing lines), click the extruder sound.

- Solution: Manually push the filament away by (hot nozzle) to clear soft blockage. implement "Cold pull" (Use nylon or cleaning wire). In severe cases, use a nozzle to clean the needle (care!). If necessary, replace the nozzle.

- Poor surface effect:

- Line string: Enable "withdraw" In the slicer settings. Make sure the nozzle/fiber temperature is not too high.

- Layer Movement: Tighten the belt and pulleys. Make sure the printer is on a stable surface. Reduce acceleration/bastard settings slightly.

- Regular maintenance: Check and tighten the bolts regularly. Clean the printing bed after printing with IPA. As needed, lubricated guide rod with PTFE lubricant. Clean or replace nozzles regularly.

Joy of making: Embrace iteration

3D printing is essentially iterative. Your first print may not be perfect – it’s part of the learning curve! Analyze, adjust settings and reprint. Celebrate small improvements. The reliability of CraftBot makes this process manageable and meaningful.

When your vision needs to be precise: Work with Greatlime

Craftbot empowers incredible personal manufacturing, complex geometry, high-strength engineering applications, demanding surface treatments or production-grade metal parts require industrial-grade solutions. This is Rapid prototyping Good at it.

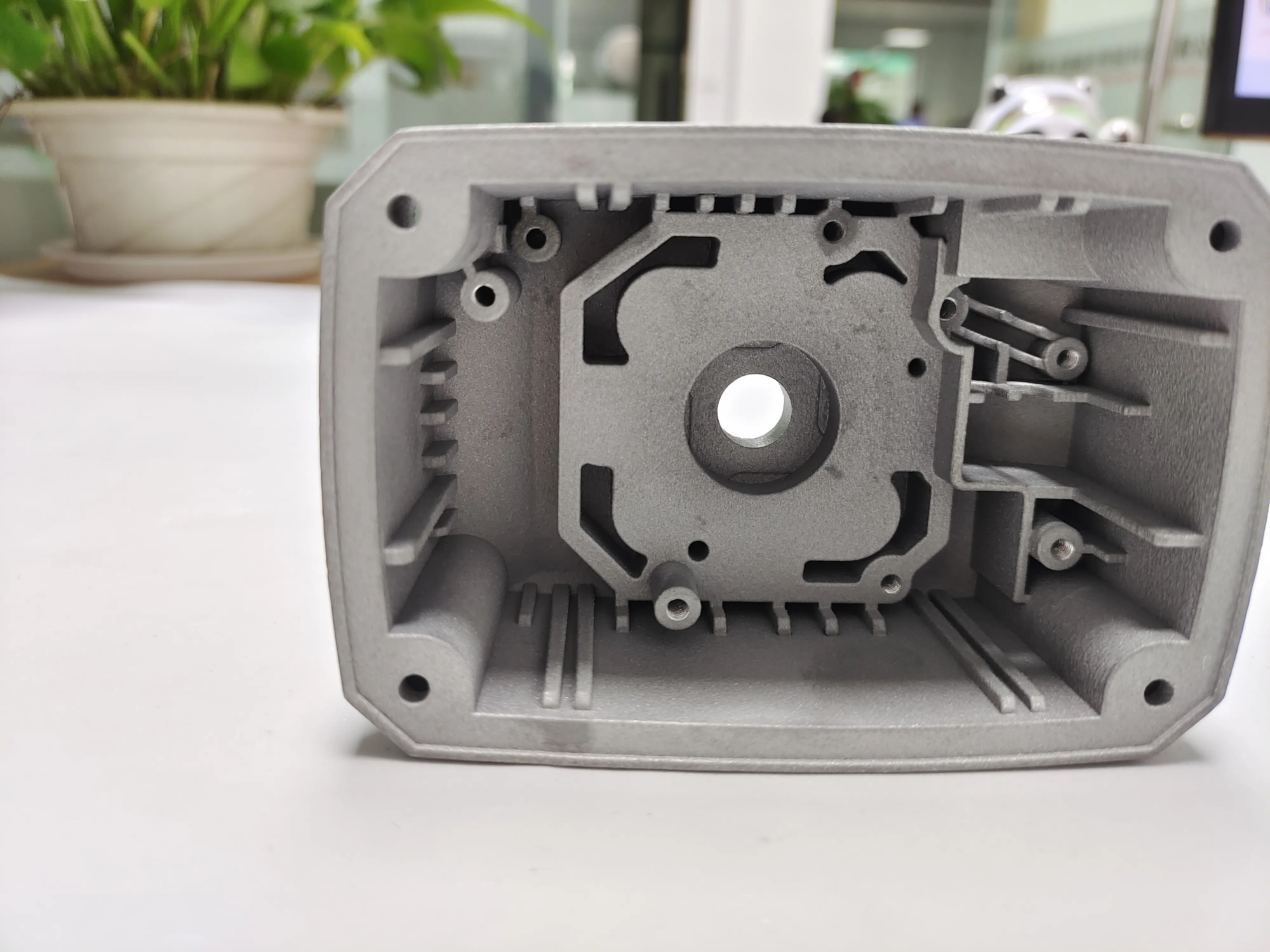

As a leading professional rapid prototyping manufacturer headquartered in China, Greatlight specializes in research Precision metal parts:

- Advanced SLM (Selective Laser Melting) Technology: Create complex, high-density metal components directly from digital design.

- Comprehensive material expertise: Used with a variety of metals (aluminum, titanium, stainless steel, inconel, copper alloy, copper steel) and plastics.

- One-stop post-processing: Provides heat treatment, CNC machining (ultra-tight tolerances outside typical 3D prints), grinding, polishing, coating, surface treatment and assembly.

- Speed and flexibility: Proficiently solve the rapid prototype challenges with fast turnaround times and material customization.

- Scalable solutions: Ideal for functional prototypes, small volume production, and custom end-use parts that require unparalleled precision and durability.

Whether your Craftbot’s passion for manufacturing has sparked the need for industrial strength solutions, Greglight is ready to be delivered at competitive prices as your partner in professional rapid prototyping and customized precision machining. Explore excellent industrial grade: [Start your project with GreatLight today!]

in conclusion

The CraftBot 3D printer is the launching platform for your creativity and technical aspirations. Its fusion of ease of use, reliability and quality output makes it the biggest competitor for anyone who risked the business of additive manufacturing. By mastering the settings, slicing, printing fundamentals, and troubleshooting, you will quickly turn your ideas into tangible objects. Remember that patience and practice are key. Enjoy the process of learning and experimenting – this is the core of the creator spirit! For challenges that take you beyond desktop printing, trust Greatlight to deliver professional-level solutions with speed and accuracy. Now, grab some of the filaments and start printing your future!

FAQ: Craftbot 3D printing and professional solutions

-

Q: What is the best filament for beginners of crafts?

- one: PLA (polylactic acid) is definitely the first choice. It is cheap, easy to print (low warping, odorless under normal conditions), has a huge color, and is biodegradable (under industrial compost conditions). Avoid starting with ABS because of its twisted trends and smoke until you are experienced.

-

Q: My prints got stuck on the bed. How to safely delete it?

- one: For Craftbot’s PEI Spring Steel Bed: Let the bed be completely cooled! The part should pop up easily. If stubborn, Gently Bend the steel plate back and forth. Avoid using sharp metal tools directly on PEI surfaces. Sometimes, keeping the entire bed in the refrigerator for 5-10 minutes can help break the adhesion.

-

Q: Is CraftBot compatible with third-party software such as Cura?

- one: Yes! Although Craftware provides optimized integration, Ultimaker Cura and Prusaslicer are excellent, often with more feature-rich alternatives. Download the default CraftBot profile for a specific model from Craftunique’s website or Slicer’s settings and choose a reliable starting point.

-

Q: How often should I maintain the crafts?

- one: Basic cleaning should occur after each printing (bed with IPA). Lubricate Z-axis lead screws/rods every 100-200 printing hours. Check belt tension regularly (bend gently when pulled out). Occasionally use a small brush to clean the extruder gear teeth. It is wise to have a wise proper calibration (upgrade after major movement/temperature, extruder step) after every few months or after any major change/failure.

-

Q: When should I consider using a professional service like Greatlime instead of a desktop printer?

- one: When your needs are involved, please participate in professional services such as Greatlight:

- Metal parts: Have functional strength, heat resistance or conductivity.

- Industrial Plastics: Materials that cannot be printed on standard FDM printers, such as standard FDM printers.

- High precision: The tolerances that can be achieved on desktop printers are tighter than ~0.1-0.2 mm.

- Complex authentication tools: The highest standards are required for the production of molds, fixtures and fixtures.

- A large number: Beyond the practicality of a desktop.

- Certified material characteristics: Aviation, medical, and automotive applications require verified data sheets and processes.

- Special post-processing: Large amounts of CNC processing, special coatings or surface finishes that require industrial equipment. GREMPHILE seamlessly provides this expertise.

- one: When your needs are involved, please participate in professional services such as Greatlight:

-

Q: How does Greatlight handle custom material requests?

- one: Gremphiem thrives on custom challenges. Their extensive material library for SLM and versatile post-processing capabilities enables them to quickly evaluate and process custom material requests. If it is feasible for industrial processes, they can often be used to use professional alloy or plastic sources and produce parts according to the technical specifications of your project.

- Q: What type of post-processing does Greatlight provide?

- one: Greatlight offers a truly one-stop solution including:

- Metal: Stress relief, aging, hips (hot isostatic pressure), CNC machining (milling, turning), EDM (electrical emission machining), grinding (surface, ID/OD), rolling, grinding, polishing, polishing (manual, robotic, robotic), anode, anode, electropolishing, electropolishing, plating, gold plating, painting.

- plastic: CNC machining, polishing, painting, dyeing, assembly.

They choose the best completion process to effectively meet your specific functional, cosmetics and dimension requirements.

- one: Greatlight offers a truly one-stop solution including: