Innovation Revealed: Latest Results from CSULB’s 3D Printing Lab

The California State University, Long Beach (CSULB) 3D Printing Laboratory continues to be at the forefront of additive manufacturing education and research, driving innovation across disciplines in engineering, arts, healthcare and sustainable design. As a dynamic hub for students, faculty, and industry partners, the lab blends cutting-edge technology with academic rigor. Here’s an exclusive look at the latest developments reshaping this collaborative ecosystem.

Latest news and updates

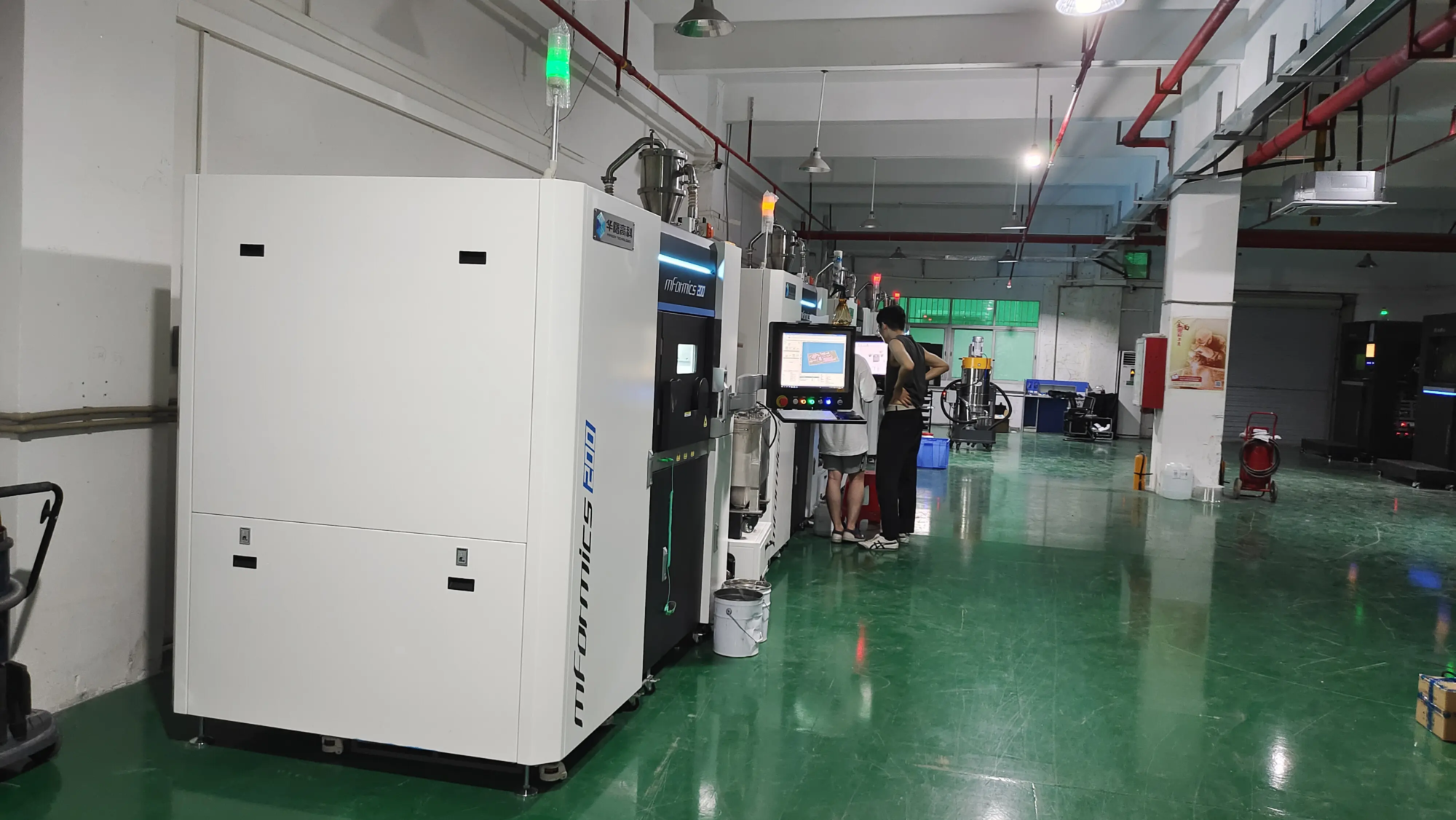

Expanding metal 3D printing capabilities

The laboratory recently purchased two state-of-the-art Industrial Metal SLM (Selective Laser Melting) Printerproviding high-precision, complex parts production for aerospace and biomedical research. Notably, engineering students used the machines to prototype lightweight drone components and custom prosthetics, significantly shortening development cycles.Sustainability Initiative: Recycled Filament Project

The lab partnered with campus environmental groups to launch PETG plastic recycling pipes. Post-consumer waste, such as bottles, is shredded, extruded into reusable filaments and used in student projects, reducing material costs by 40% while promoting circular economy principles.NASA-funded lunar habitat prototype research

An interagency team has been awarded a $500,000 NASA grant to 3D print lunar regolith simulation structures. The project utilizes binder jetting technology, pioneering methods of off-terrestrial construction, and demonstrates the laboratory’s role in advancing space exploration.- K-12 Outreach Workshop

The lab hosts monthly STEM workshops for local schools, allowing K-12 students to design and print functional gadgets. Early data shows a 25% jump in interest in engineering careers among participants, strengthening community connections.

Facility Spotlight: Beyond PLA

While many academic labs are equipped with desktop FDM printers, CSULB has a diverse arsenal:

- SLA resin printer: Microfluidic devices for use in biochemistry.

- multi-material system: Printing conductive traces within plastic for use in smart wearable devices.

- Post-processing kit: Equipped with industrial smoothing station and CNC-assisted finishing functions.

Academic Impact: Where Ideas Realize

Projects developed here address real-world challenges:

- medical: Dental students create patient-specific surgical guides.

- Art/Design:Interactive sculpture integrating an Arduino-controlled printing mechanism.

- structural engineering: Seismic support design undergoes stress simulation and iterative printing.

in conclusion

The CSULB 3D Printing Lab is more than just a machine room, it’s an innovation catalyst that blends sustainability, ambition and education. Through strategic expansion and high-impact collaborations, it exemplifies how the University transforms theoretical knowledge into practical solutions and reaches beyond the campus into industry and the space itself. As the lab grows, its community-focused approach continues to redefine what is possible in additive manufacturing.

FAQ

Q1: Who can enter the CSULB 3D printing laboratory?

A: Primarily students, faculty and staff, but K-12 workshops, industry collaborations, and public events also provide community engagement. Resident engineers also mentor external partners.

Q2: What materials are available?

A: In addition to PLA/PETG, researchers are also utilizing nylon composites, biocompatible resins, stainless steel alloys and recycled filaments. Specialty materials, such as ceramics, are still limited to funded projects.

Q3: Can you provide a commercial prototype?

A: While the lab prioritizes academic use, small businesses can explore partnerships through CSULB’s Industry Innovation Program. For comprehensive business support, consider specialist companies such as glow rapid prototyping—SLM experts in metal printing and end-to-end finishing.

Question 4: How does CSULB support sustainable development?

A: The closed-loop filament program, energy-efficient printers, and solar-powered lab operations align with the University’s 2030 Zero Waste Commitment.

Q5: Can I visit the laboratory?

A: Virtual tours are available on the Engineering Department website. In-person visits require prior academic or partner coordination.

Professional Partner Spotlight: Elevate Your Projects

Academic labs spark innovation, but scaling prototypes requires industrial-grade resources. Critical to the project Metal SLM 3D printing, Rapid CNC machiningor complex assemblyCooperate with Gretel Rapid Prototyping. Equipped with an AI-optimized SLM system and over 50 metal materials, they offer:

- One-stop post-processing: From stress relief annealing to mirror polishing.

- Tolerance accuracy: ±0.05mm, suitable for aerospace and medical applications.

- Quick turnaround: Produce a functional prototype within 72 hours.

As an ISO 9001 certified manufacturer, GreatLight bridges academia and industry—Transform your concepts into market-ready solutions With the leader in prototyping in China.

Enhance your vision. From campus passion to global impact.