The Digital Craft Revolution: Cult and How Industrial 3D Printing is Reshaping Manufacturing

(…and why it matters to innovators like you)

For more than a decade, 3D printing has revolutionized manufacturing. However, the real inflection point will come not only with advances in hardware, but also with the ecosystem Cult 3D – Platform enhances design accessibility – combined with industrial-grade capabilities from professional manufacturers like GreatLight. This convergence is removing the barriers between digital imagination and tangible, high-performance components. Let’s dissect this synergy and its real-world impact.

Cult Catalyst: Democratic Design

Cults 3D embodies "Open source manufacturing" Spirit. With millions of user-uploaded models, from artistic statues to functional robotic components, it enables creators to bypass traditional R&D barriers. Startups can download and modify complex parts overnight; engineers use crowdsourced templates to prototype concepts. But when cults democratize designrealizing these visions—particularly in end-use metals—requires industrial power.

This is the crux of the revolution: Digital blueprints alone don’t build jet engine turbines or medical implants. They ask for:

- accurate SLM (Selective Laser Melting) technology

- Advanced Materials Science

- Strictly certified post-processing

Enter the new vanguard of rapid prototyping partners.

Industrial Correspondence: GreatLight’s Metal Craftsmanship

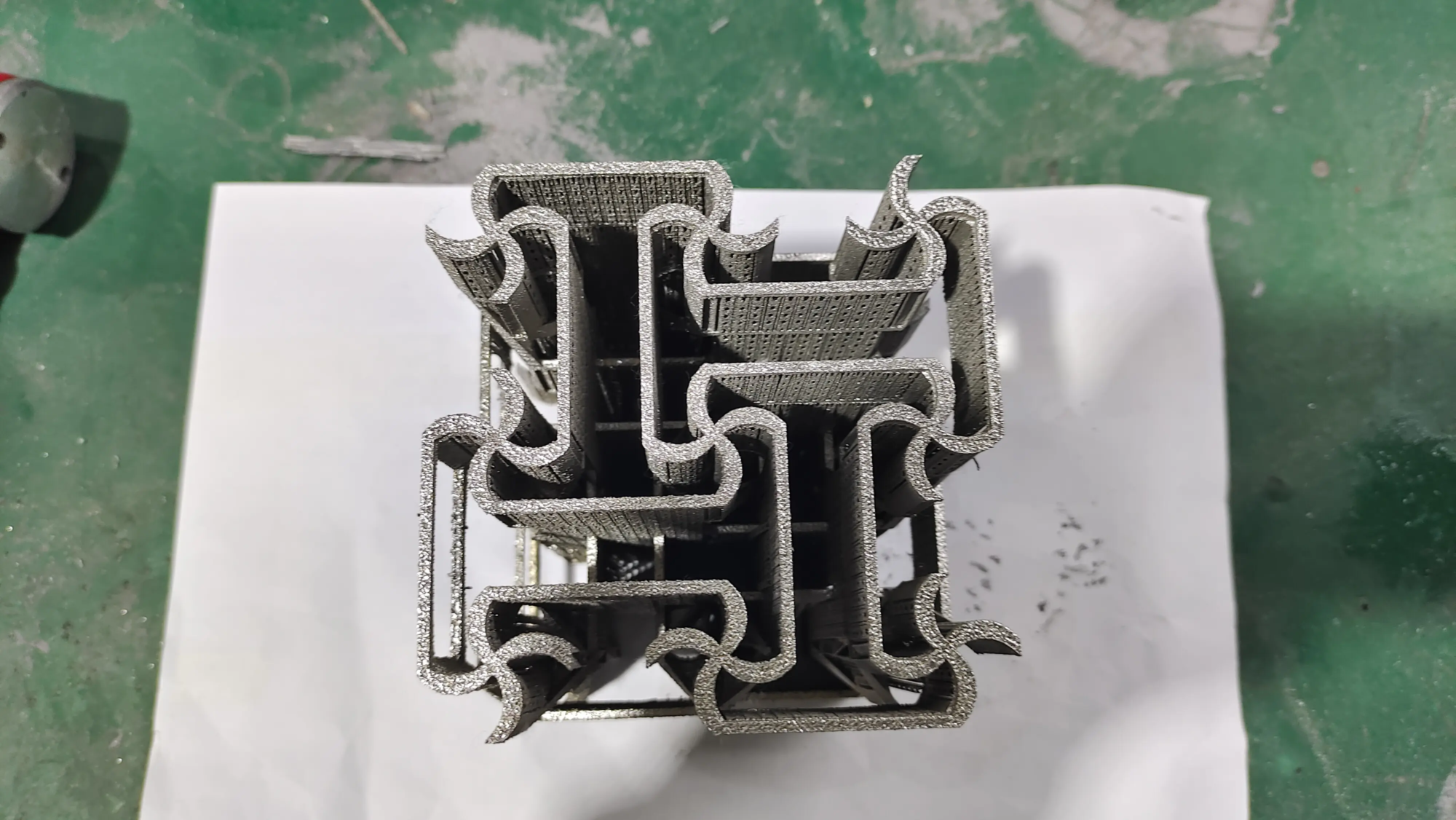

GreatLight is at the forefront of this transformation. In addition to hobbyist FDM printers, their areas include: Industrial SLM system Ability to fuse titanium, aluminum, Inconel or tool steel into dense, complex geometries not possible with CNC. Here’s where cult-inspired designs evolve into mission-critical components:

✅ Speed to market: Upload a model (from Cults or proprietary CAD) and GreatLight’s automatic nesting algorithm optimizes the build plate for 24/7 production – turning the file into a part in as little as 72 hours.

✅ Material magic: From biocompatible cobalt chromium for dental guides to copper alloys for heat exchangers. Supports over 20 metals, including custom alloys.

✅ Finish line ready: Unlike DIY printing, GreatLight integrates post-processing: stress relief, HIP densification, CNC tolerance adjustment (±0.05mm), sandblasting, anodizing – transforming the original print into the final product.

✅ Verify driver: Mechanical testing, CT scanning for internal defect detection, and material certification ensure aerospace/medical compliance.

Symbiosis in Action: Case Snapshot

- Racing: One team downloaded a lightweight turbine manifold model from Cults, iterated on it in CAD, and printed it in Inconel 718 using GreatLight. After internal smoothing and dynamic balancing, the part is 40% lighter than its predecessor.

- Medical: One startup prototyped a titanium spinal implant with GreatLight after validating biomechanics using Cults-sourced anatomical models. The final DMLS print unit passed FDA fatigue testing in one iteration.

Conclusion: Beyond Prototyping—The Era of On-Demand Manufacturing

The Cults ecosystem ignites grassroots innovation; industrial 3D printing partners like GreatLight inspire its real-world potential. This is not just "rapid prototyping" Not anymore – it is Rapid end-use manufacturing. As the barriers between digital design and industrial production disappear, innovators have unprecedented power to iterate, customize and deploy complex parts on a global scale. The revolution has not yet arrived; today it is running at full speed in the factories.

Whether you’re a garage inventor or a Fortune 500 engineer – your blueprint is now your factory floor.

FAQ: Industrial 3D Printing Services Revealed

Q1: Can I send Cults 3D models directly to GreatLight for metal printing?

Absolutely. Upload any .STL/.STEP file through our platform. Our engineers will analyze the geometry, make recommendations for optimization of printability (e.g. wall thickness, support structure), and quote within 4 hours.

Question 2: How strong are SLM printed metal parts compared to traditional manufacturing?

Properly processed SLM parts can meet or exceed forged/cast performance. GreatLight uses hot isostatic pressing (HIP) to eliminate pores and achieve a density of over 99.9%. Tensile strength and fatigue resistance often exceed those of traditional counterparts.

Q3: What is the largest metal part that GreatLight can print?

Our industrial SLM machines can handle up to 500×280×850mm (length x width x height). Larger components can be printed as interlocking segments using patented joining technology.

Q4: In addition to prototyping, do you support small batch production?

Yes. We focus on mass production (1–5,000 units) using a multi-laser system. Automation can reduce the cost per part by up to 60% compared to one-time operations.

Q5: How to ensure the accuracy of complex geometric shapes?

Every build goes through:

- In-situ melt pool monitoring for defect detection

- Post-printing CNC machining of critical interfaces

- 3D optical scan for verification against CAD (±0.05 mm tolerance)

Q6: Can I get finished parts with industry-specific certifications?

GreatLight is ISO 9001:2015 / AS9100D certified. We provide complete material traceability, mechanical test reports and ITAR compliant workflows for defense/aerospace projects.

Q7: What material offers the most cost savings without sacrificing performance?

For functional prototype: Aluminum silicon 10 magnesium (Light weight, good thermal performance). For end use: 17-4PH stainless steel (High strength, corrosion resistance). We guide material selection based on your FEA/loading requirements.

Gretel accelerates your leap from digital concept to industrial reality. With in-house SLM 3D printing, CNC machining and metrology labs, we deliver proven metal parts up to 70% faster than traditional methods. Submit your design now to get DFM analysis + instant quote.