The perfect ending: How custom metal 3D printed cake decor can enhance your celebration

Imagine the following picture: The heart of your carefully planned activity, the cake caught people’s attention. But what really makes it memorable? Champion – Cake topper. While traditional plastic or resin trim has its place, the emerging customization wave blends artistic, durability and pure WOW factors: Custom metal 3D printed cake top hat. They are not only decorations, but also a precious heirloom that embodies the unique nature of your special moments.

Beyond Sugar and Frosting: The Charm of Metal

Why metal? The answer lies in its unique attributes:

- Unrivaled details and precision: Unlike materials that are prone to warping or blurring, metal 3D printing is especially used Selective laser melting (SLM) Technology to capture complex details with amazing loyalty. Consider delicate lace patterns on your wedding dress, fine hairs of beloved pets recreated for birthdays, intricate company logos, and even miniature portraits.

- Strength and stability: Metal provides structural integrity that paper, plastic or fudge simply cannot match. It’s tall and has no bends, swaying or succumbing to humidity, ensuring your top hat looks perfect throughout the event.

- Timeless elegance and sophistication: Metals such as stainless steel, brass, gold-plated steel or titanium provide a unique high-quality aesthetic. They capture the light beautifully, adding a sophisticated and luxurious finish to any cake design.

- Beyond Events: Plastic top hats are often discarded. Customized metal trim turns into precious souvenirs. It can be displayed indefinitely – on shelves, on tables, and even turned into ornaments. It has the tangible weight of your memory.

- Final Customization: real any Design is possible. A couple riding dinosaurs instead of limousines? Scaling model of your first home? Your child’s favorite cartoon character? Metal 3D printing turns even the most unique field of vision into a tangible reality without the limitations of traditional molding techniques.

Huge difference: Print perfectly on every detail

Creating these miniature masterpieces requires professional expertise and cutting-edge technology. This is where Greatlight is good at. As a professional rapid prototyping manufacturer specializing in the manufacturing of high-precision metal additives, we bring unparalleled advantages to custom cake toppers:

-

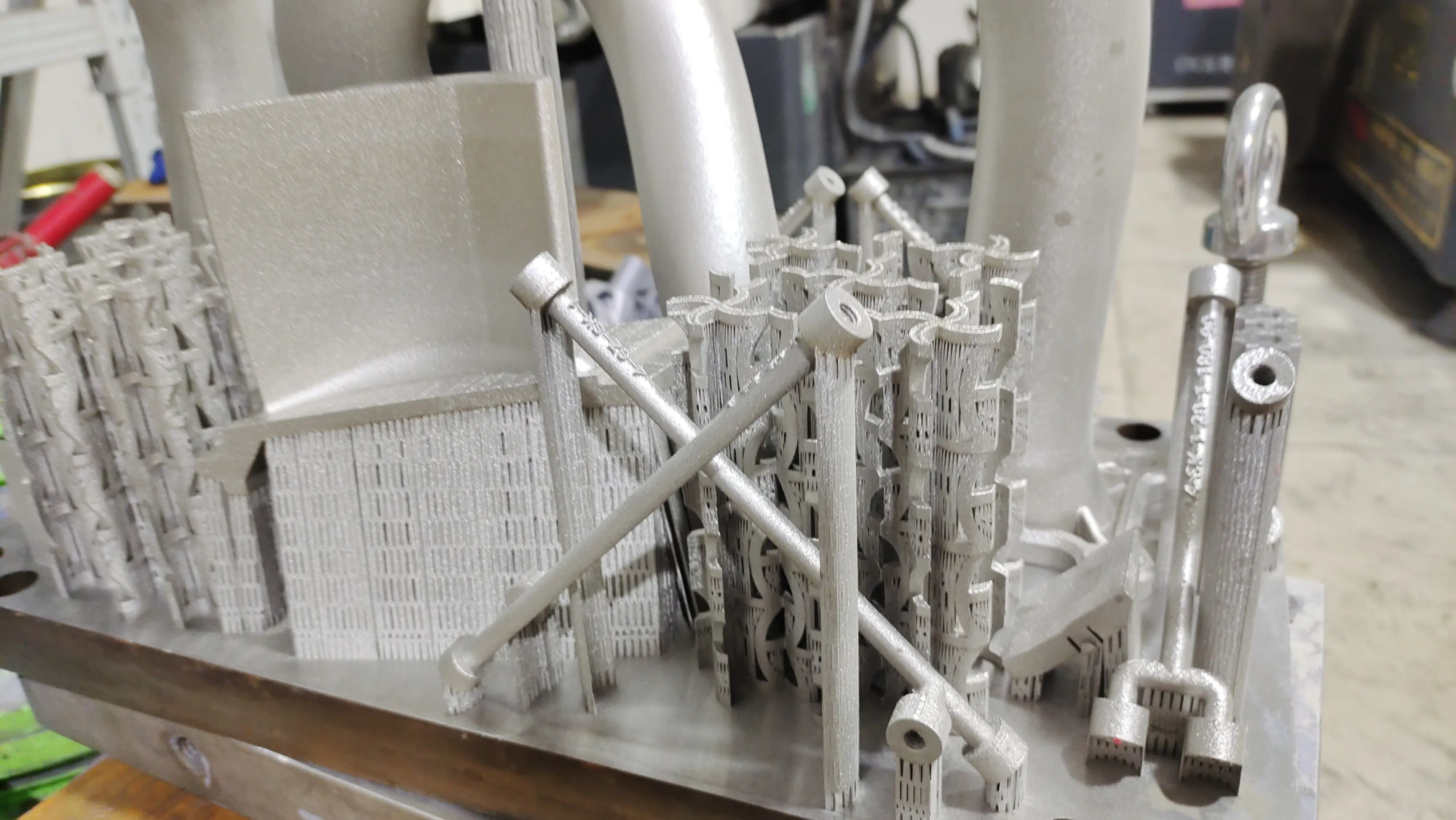

Advanced SLM technology: Our industrial grade selective laser melt printers use powerful lasers to fuse beautiful metal powder layer by layer. This ensures:

- Excellent resolution: Perfectly capture microscopic details until textures and thin lines work.

- Material integrity: Produces completely dense, robust parts that are perfect for handling.

- Geometric freedom: Complex undercuts, lattice structures and organic shapes are impossible by traditional methods.

-

Material expertise and choice: In addition to standard stainless steel, we also offer a variety of customizable options:

- Stainless Steel (316L): Durable, corrosion-resistant, affordable brilliance.

- brass: Rich, warm tones are perfect for retro or rich themes.

- titanium: Lightweight, exceptionally powerful with a unique modern grey finish.

- Precious metals gold plating (gold, silver, rose gold): Add a layer of luxury to the steel plate. We can discuss specific alloys to achieve the desired appearance and characteristics.

-

Comprehensive post-processing excellence: Printing is just the beginning. Our one-stop finishing service changes original printing:

- Support removal: Carefully disengage without compromising complex features.

- Surface smooth: Techniques such as tumbling or precision blasting to achieve the desired texture – matte, satin or smooth.

- polishing: The mirror finish makes the high-end look dazzling.

- plating: Plated with expert gold, silver, rose gold or nickel.

- PATINATION/Chemical pigment: Create a unique antique or artistic finish on brass.

- Final Cleaning: Ensure original, reliable food is safe adjacent to the surface (note: the metal pullover is on the cake board or on the base, rather than embedded directly in the frosting that can react with the metal).

-

Rapid Prototyping: Need a last-minute design tweak or a crunch deadline? Our core business is to iterate manufacturing industry rapidly. We use this expertise to provide effective turnaround time for your custom top hat without compromising quality. Design, Print, Finished – Simplified.

- Ensure accuracy: We understand that demanding industrial applications are rooted in rapid prototypes. Your vision is translated with meticulous precision to ensure the final product matches your design perfectly.

Design your dream top: Key things to note

For the most amazing results, remember these results when creating your design files:

- Proportion and proportion: Define the exact dimensions. Consider the size of the cake and the desired highlight. We usually deal with rows of clothes from a few centimeters to an impressive height. Make sure elements like characters or text are large enough to print securely.

- Stabilization and weight: While metal adds weight (a feature!), make sure the center of gravity of the design is firmly located on the base. We can recommend integrating weighted foundations or strategic structure support.

- Rounded corners and support optimization: The sharp inner corner may be a stress point. Smooth rounded corners improve strength and printability. Our engineering team can assist in optimizing the productivity of SLM and minimal support structure design for better results.

- Resolution focus: Emphasize important details. Upload high resolution vector files (preferred for 2D elements) or well-crafted 3D CAD models (STL, OBJ). The clearer the design intention, the better the result.

- Consult an expert: Not sure about the best material or finish for your theme? Not sure about the optimization model? Take advantage of Greatlight’s expertise! Our team can provide valuable design feedback and advice.

Where does the metal sleeve shine? (Obvious!)

While weddings are the main candidates (unique monograms, outlines, detailed scenes), their applications are extensive:

- Anniversary: Recreate wedding photos or important symbols in metal.

- Milestone Birthday: (No. 18, 21, 30, 40, 50th+, etc.).

- Company Activities: Brand logo, celebrating product launch, anniversary or major achievement.

- Baby Shower/Bathing: Personalized baby blocks, tiny footprints, symbolic animals.

- retire: Symbolized occupational elements (e.g., the judge’s miniature gavel, tiny scale).

- Food and Cooking Activities: Complex chef’s hat, stirring or abstract culinary art.

Conclusion: Improve, personalize, cherish

Custom metal 3D printed cake toppers represent the pinnacle of personalized celebration decorations. They transcend the ephemerality of events and become elaborate symbols of precision and lasting beauty. These garments combine artistic freedom with the technical strength of SLM 3D printing and professional finishes, adding undeniable luxury and meaning.

At Greatlight, we don’t just print objects; we help you bring your most meaningful moments to life in a tangible, lasting form. Our commitment to advanced technology, material expertise, strict quality control and comprehensive completion enables us to deliver authentic artworks of custom metal cake toppers. Ready to turn your dessert table core into a masterpiece and precious souvenir to start the conversation? Explore endless possibilities with Greatlight’s custom 3D printing expertise.

FAQ: Your Custom Metal 3D Printed Cake Topper Questions Answered

Q1: Can a metal cake top hat be placed on a cake safely?

A: Usually, yes! Metal trim usually sits on a cake board, base plate or base instead of being embedded directly into an edible frosting/sauce, which can lead to adverse effects. Greatlight uses biocompatible metals such as certified food-safe stainless steel (316L) and ensures a thorough post-processing cleaning. We recommend placing them firmly with inedible support exist A cake with absolute peace of mind.

Q2: How durable are these metal trim panels?

A: Very durable! Made of materials like stainless steel, brass or titanium, they are stronger than plastic, resin or fondant finishes. They resist rupture, shattering and warping. With proper care, they can continue to cherish souvenirs indefinitely.

Q3: What is the typical turnover time?

A: Turnover depends on design complexity, selected materials, finishing process, and our current workload. We take advantage of fast prototyping efficiency – can reverse simple designs in a few days; more complex or require multiple completions to take 1-2 weeks. Contact us with your details for a solid quote and schedule.

Q4: What file format does your design require?

A: We prefer high resolution 2D vector files (SVG, AI, DXF) for logos or text outlines, or high-quality 3D model files (STL, OBJ, STEP, IGES). The more detailed the cleaner and details, the better we start.

Q5: Can I do polishing or plating of the design?

Answer: Absolutely! Greglight offers a wide variety of One-stop post-processing options: Brush or polished finish for gloss, satin/matte bead blasting, plating with gold/silver/rose gold/nickel as well as chemical colors/jewelry for unique effects (especially on brass). Talk to us about the aesthetic you want.

Question 6: What is the price range?

A: Costs vary based on size, material, metal quantity, complexity (affecting printing and support time), and completion requirements. While essentially better than plastic, they offer great value through durability, uniqueness and heirloom potential. Contact Greatlight with your concept for competitive and transparent quotes tailored to your vision and budget.

Ready to create an amazing, unique focus for your celebration? Explore the art of possible with Greatlight’s custom 3D printed metal cake topper.