The Art and Function of Custom 3D Printed Ashtrays: Blending Nostalgia with Modern Precision

Ashtrays have a unique personal touch. For generations, they have been more than vessels; They are coffee table conversations, silent witnesses of shared moments, and even reflections of personal style. While mass-produced stamped metal or ceramic ashtrays were once common, today’s discerning consumers crave ashtrays that resonate with a personal sense. where is this Custom 3D printed ashtray design Step in to transform functional items into custom objects imbued with meaning, aesthetics and unparalleled precision. It’s about elevating something familiar into something unique yourcapturing memories and preferences in a tangible form.

Why choose custom 3D printed ashtrays?

Traditional manufacturing methods severely limit the design of ashtrays. Complex shapes, complex textures, integrated features or personalized elements are often very expensive or impossible to achieve with molds or machined fade moldings. Custom 3D printing breaks these limitations:

- Unparalleled personalization: From incorporating names, dates or meaningful symbols to reflecting specific hobbies (e.g. cars, music, nature), the only limit is your imagination. Imagine a deep-dish ashtray modeled after a vintage camera lens, with swirling ridges reminiscent of a film reel, or a sleek, modern ashtray with an integrated cigar strap holder.

- Functional innovation: Design is more than just looks. Custom designs can optimize functionality:

- Strategically placed cigarette/cigar racks won’t impede airflow.

- Ergonomic contours match hand placement.

- Optimized airflow vents minimize lingering smoke odor.

- Segmented compartments to store ashes/cigarettes/matches.

- Integrated moisture protector for humidors.

- Material Versatility: Unlike traditional methods that rely on specific materials, 3D printing offers a variety of options to suit aesthetics, durability, and feel:

- Stainless steel: Highly durable, heat resistant, easy to clean, modern industrial aesthetic. Ideal for outdoor or high traffic environments.

- titanium: Extraordinarily strong, lightweight, naturally corrosion-resistant, top-quality materials for a premium feel.

- Nickel alloy: Excellent high temperature stability and corrosion resistance, ideal for heavy cigars or pipes.

- Polymer/Nylon (Prototype/Concept): Used to quickly prototype design concepts before going to metal.

- Shorten ideas to reality: For designers, artists or collectors who want a unique piece, 3D printing bypasses the lengthy setup and molding costs associated with traditional methods, making custom items feasible.

The GreatLight Advantage: Precision and Customization

At GreatLight, we know that turning your vision for a custom 3D printed ashtray into a flawless reality requires more than just a printer. As a specialist rapid prototyping manufacturer, our expertise ensures your concept reaches its target with unparalleled professionalism:

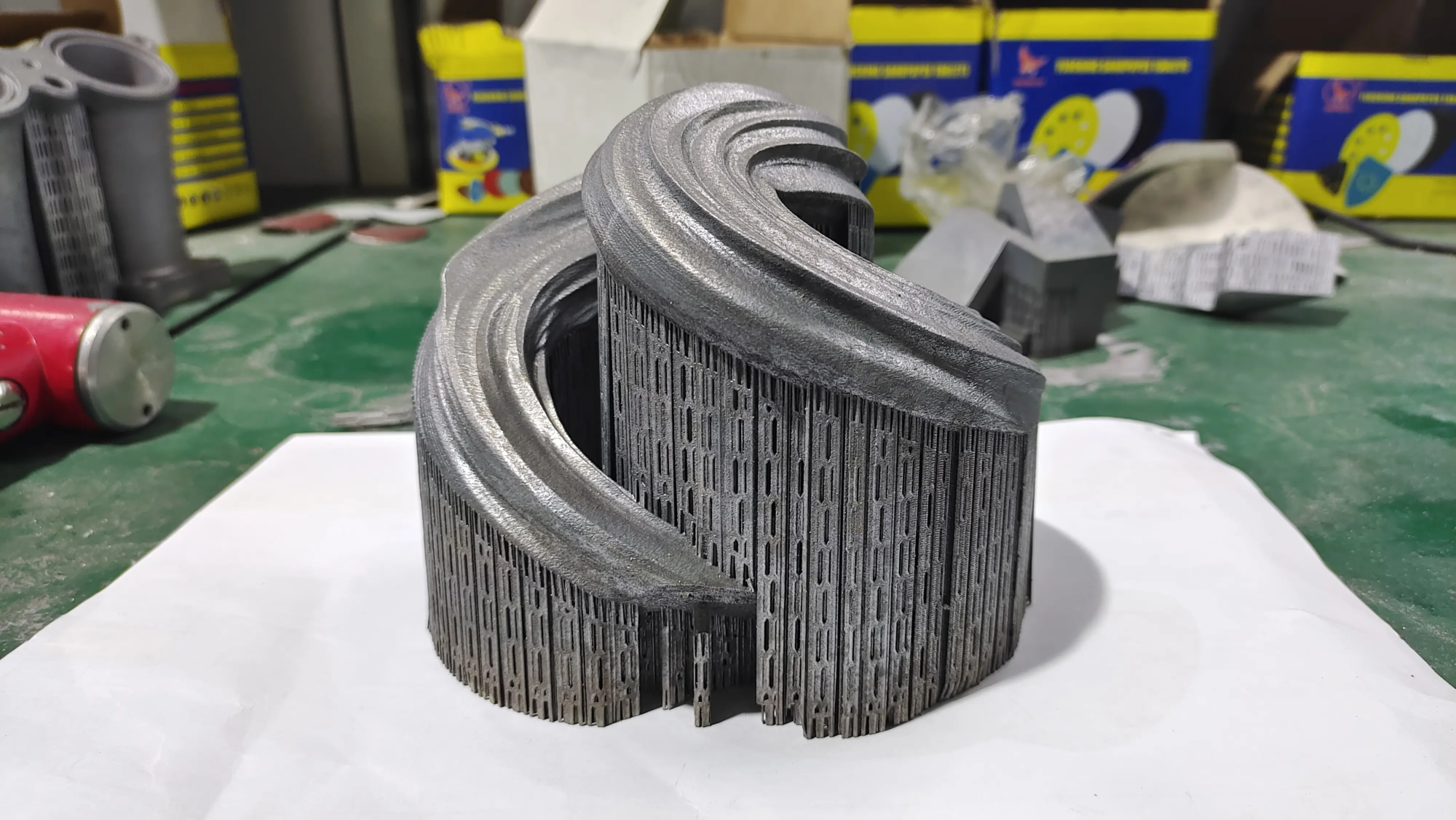

- Advanced Metal Additive Manufacturing: Utilize state-of-the-art technology SLM (Selective Laser Melting) 3D Printerwe build complex metal geometries layer by layer directly from your digital design (CAD model). This patented technology produces dense, strong and precise metal parts necessary for durable, functional ashtrays (bubble effect check).

- Materials Science Expertise: We don’t just print; we understand the materials in depth. We provide recommendations for the best metal alloys based on your needs – emphasizing the heat and corrosion resistance durability of stainless steel and titanium grades. Most materials can be quickly sourced and processed to your specifications.

- Professional one-stop finishing: Printing is often just the beginning. Our comprehensive post-processing department handles everything needed for a high-quality end product:

- Support removal: Carefully remove the sacrificial structures used during the printing process.

- Stress Relief/Heat Treatment: Enhance material properties and ensure dimensional stability.

- Precision machining: Achieve ultra-tight tolerances on critical mating surfaces or threads.

- Advanced surface treatment: From easy-to-clean smooth mirror polish, vibrant colored ceramic coating (PVD), refined sandblasting (matte look) or unique textured finishes.

- Engraving/Marking: Add personalized text or logo with laser precision.

- Rapid prototyping core capabilities: addressing "Rapid prototyping issues" is our specialty. We excel at rapidly iterating designs, identifying potential manufacturability issues early and, where applicable, using advanced simulation tools to optimize geometry for aesthetics and structural integrity. This strict requirement ensures that your custom ashtray not only looks great, but always performs perfectly.

- Quality and precision focus: As one of the top rapid prototyping companies in China, quality assurance is crucial. We use rigorous inspection techniques (dimensional inspection, visual inspection) to ensure that each custom ashtray meets precise specifications.

Create your unique smoking accessories

Designing a custom ashtray starts with conceptualization. consider:

- Trenching (impact angle dependence): Size, shape (round, oval, geometric), depth – optimized for academic cigars.

- rest: Quantity (one-handed convenience vs. multi-user convenience?), grooved style mecha, nice angles.

- feature: Finger impression grooves, integrated match holder, integrated nozzle wrap track, cigar recycler holder, ventilation slots/holes (design potatoes).

- aesthetics: Minimalist/modern, vintage, organic shapes, fractal grid patterns, abstract forms, tribal ethnic patterns.

- Material/Surface Treatment: Highly polished metal with a subtle brushed texture and a deep matte coating (PVD). Weight and feel are important.

Share your vision with our designers or engineers. We provide DFM (Design for Manufacturability) feedback, suggesting optimizations for printability, strength, ease of processing and cost-effectiveness without compromising your core concept.

Conclusion: Beyond practicality, towards legacy

Custom 3D printed ashtrays go beyond mere functionality. It becomes a statement, a reflection of personality, a conversation starter and may become one of his remains to be cherished. With modern additive manufacturing technologies such as SLM and the expertise provided by specialist partners such as GreatLight, it is now possible to create unique heirloom-quality ashtrays. No more settling for generic items. Combine your imagination with precise engineering and quality materials to create an ashtray that truly resonates with your story and aesthetic.

FAQ: Custom 3D Printed Ashtrays

-

What materials are best for 3D printing ashtrays?

Stainless steel (316L/304) is generally the most popular choice due to its excellent durability, heat/corrosion resistance and cost-effectiveness. Titanium has an excellent strength-to-weight ratio and exceptional appeal. Nickel alloys have excellent heat resistance. We provide recommendations based on your specific use case and aesthetic.

-

Can I 3D print any design?

almost! While SLM technology offers tremendous geometric freedom, the design is subject to cyanide constraints such as unsupported overhangs, extremely thin walls, or internal channels that require supports. Our technical team provides DFM analysis to optimize your design for successful printing and functionality.

-

How heat-resistant is a 3D printed metal ashtray?

Metals such as stainless steel (316L) and titanium (grade 2) have high melting points (>1300°C, well above cigarette/cigar ember temperatures of ~700°C) and are specifically selected for their thermal stability. Proper design can avoid the creation of extreme localized heat traps. Heat conduction on the exhaust surface helps to dissipate heat efficiently.

-

Are they easy to clean?

Finished stainless steel and titanium are very easy to clean. Polished finishes wipe clean easily; textured finishes may benefit from careful brushing. Avoid using abrasive cleaners on coated surfaces (PVD/coating). Print-on-demand smooth designs improve cleaning results.

-

How much does a custom 3D printed ashtray cost?

Cost depends largely on size, material selection, complexity, volume (simple disposable rollers vs. complex batches) and finishing requirements. Because tooling costs are eliminated, custom parts can often be produced more economically than the comparable complexity of using traditional methods.

-

How long does it take from design to finished product?

Timetables vary. A simple design using readily available materials, with basic touch-ups, may require a few days’ notice. Complex large workpieces requiring extensive post-processing (multi-step finishing/custom machining) may take days. GreatLight prioritizes quick turnaround and quality.

-

Can I provide my own CAD files?

Absolutely! Providing well-defined, impeccable CAD files saves a lot of time. We support major formats (STEP, STL, .IGES/SLDPRT). Our engineering team can also assist in creating or refining CAD based on the meaning of your sketches/concepts.

- Are there any restrictions on the copyrighted logos or designs I can use?

Yes. You must obtain appropriate permissions/permits for your branding project Protected trademarks Copyrighted material Posters Ready for loud sounds Interior selection Operable materials Pedals