The Future of Game Control: Custom 3D Printing Steering Wheel

In the world of simulation racing, precision and immersion are not negotiable. As players push for a realistic experience, ready-made equipment is often insufficient. Enter Custom 3D printed steering wheel– Compensation for the revolution of personality and engineering excellence. Gone are the days of compromise on grip angle or button placement. Today, custom peripherals are tailored to your hands, racing styles and aesthetic preferences are redefining competitive games.

Why 3D printing is a game-changer

Traditional manufacturing relies on quality to produce molds, thus limiting design flexibility. 3D printingHowever, use conventional methods to enable complex geometry. For steering wheels, this means:

- Perfect ergonomics: Scan your hand posture to create anatomically molded grips, reducing fatigue during endurance races.

- Integrated features: Embed the mount into the screen, custom button panel or tactile sensor directly into the wheel structure.

- Lightweight power: Aluminum alloys or polymers infused with carbon fibers (such as aluminum alloys) provide aerospace-grade material that is rigid without penalty.

Professional Racer and SIM Jack Miller Note: "The switch to 3D printing wheel is transformed. The balance and feedback are different from any retail model I use."

Great Advantages: Engineering your Vision

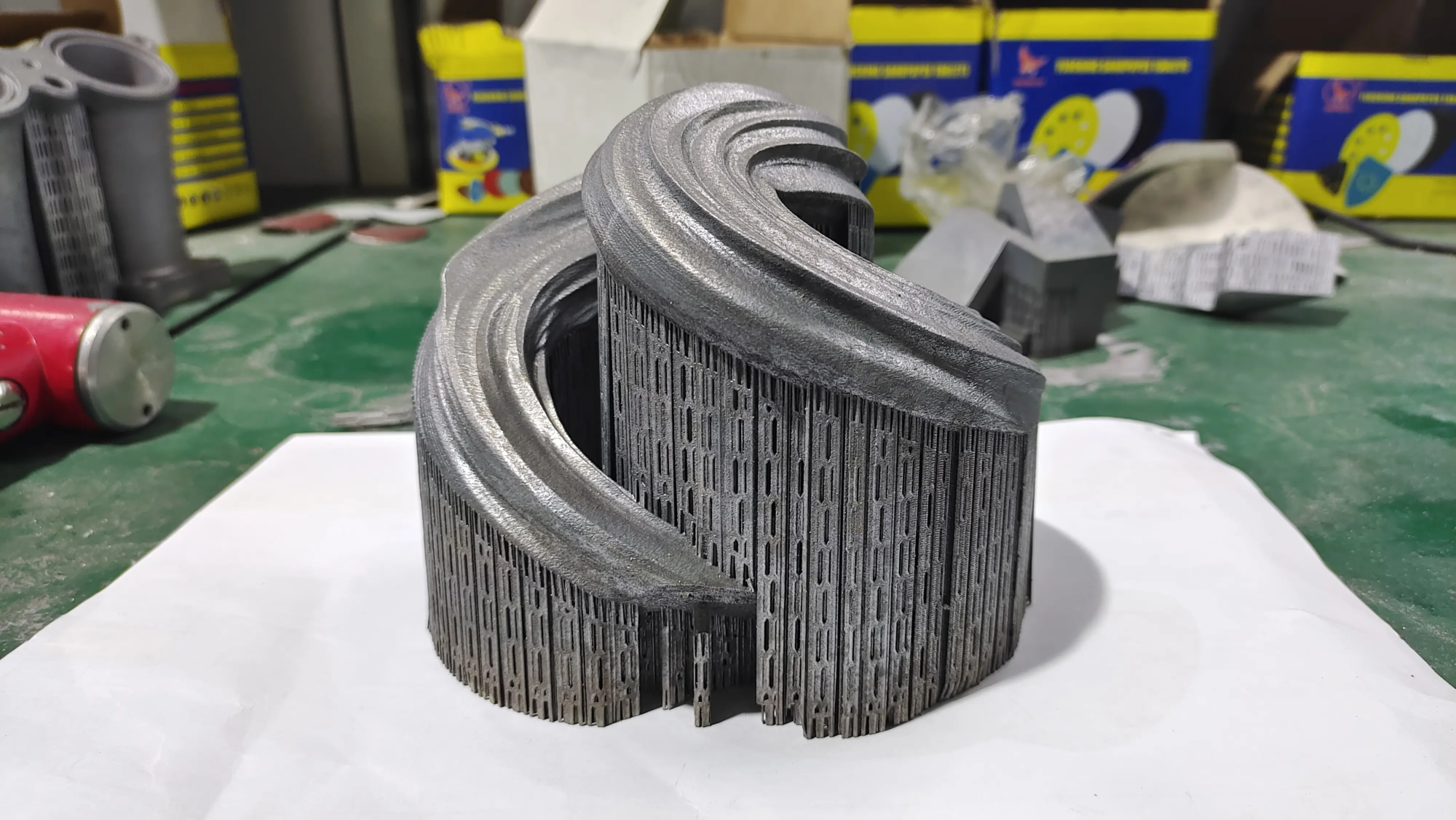

exist Greatwe merge Industrial SLM (Selective Laser Melting) 3D Printer Precision CNC completes excellent performance of wheels in delivery form and functionality. Our process ensures:

- Material versatility: Choose from titanium for unrivalled durability, lightweight aluminum alloy or high temperature resin. Do you need vibration? We integrate the elastic layer.

- Rapid prototyping: Iterative design in a few days rather than months. Test ergonomics based on actual feedback, adjusting thumb depression or adjusting paddle transmission angle.

- One-stop post-processing: From bead blasting for frosted finishes to CNC-filled button slots and waterproof paint, we can handle all the details.

🔧 Case study: A wheel that a customer requests to embed the rotational force feedback sensor in the spoke. Our SLM printers use internal channels to create hollow, weight-optimized structures while post-processing ensures perfect component integration.

Beyond Aesthetics: Performance Release

Custom wheels are more than just vanity projects – they are precise tools. Key innovations include:

- Heat-resistant grip: Palm of hand that is filled with glass to withstand sweat in high-risk matches.

- Dynamic weight distribution: Adjustable tungsten weight can be inserted into fine-tuned rotational inertia.

- compatibility: Designed to integrate with basics such as Fanatec, Thrustmaster or DIY Direct-Drive Systems.

Creation Journey: From Concept to Drilling

- Design consultation: Share sketches, manual measurements or CAD files. Our engineers optimize printability and strength.

- Material selection: Balance weight, stiffness and budget (e.g., aluminum and titanium used for use in Pro).

- Printing and finishing: The construction layer of the SLM printer is as thin as 20 µm. Post-treatment includes smoothing, sealing and color anodizing.

- Quality verification: Stress test grip, verify button responsiveness and ensure bolt compatibility.

Why gamers choose Greatlight

- speed: The prototype is shipped within 72 hours; all production within 10 days.

- accurate: Accuracy of ±0.05mm size.

- Scalability: From single-use wheels to e-sports team batches.

- Cost-efficiency: No mold fee + material optimization = 30–50% savings with small batch injection molding.

in conclusion

Custom 3D printed steering wheels represent the pinnacle of personalized performance. They eliminate compromises, enhance immersion, and empower racers through controlled racers that feel like an extension of their bodies. For developers, esports teams or dedicated amateurs, integrating ergonomic innovation with cutting-edge manufacturing unlocks unprecedented potential.

Are you ready to dominate the track? Your dream wheel starts with the blueprint and brings it to life.

FAQ: Custom 3D printed steering wheel

Q1: How durable are 3D printed wheels compared to commercial wheels?

A: When printed with metals such as Alsi10mg or titanium, they exceed retail plastic wheels in a strength-to-weight ratio. Greglight’s aerospace-grade alloys are heat treated to enhance fatigue resistance.

Q2: Can I add my own logo or texture?

Answer: Yes! Laser engraving, embossed texture or injected tinting coatings can personalize the wheels. Submit vector files during design.

Q3: What is the pricing range?

A: Basic aluminum models start at $350 – $600; titanium or multi-material versions reach $900 – $1,500. Complexity, size and finish choice can affect cost.

Question 4: Do you support electronic component integration?

Answer: Absolute. We design wire routing channels, screw mounts for PCBs, and waterproof seals for buttons/encoders.

Question 5: How to provide measurements for ergonomic grips?

A: Share 3D hand scan, photos or detailed sketches with reference scales. We will use biomechanical templates to model grip.

Question 6: Are these compatible with console racing games?

A: Yes, as long as the bottom of the wheel supports console connections (for example, through the fanatec ecosystem). We have adjusted the installation system to basic specifications.

Unlock your advantages –Contact Greglight Carry out free design consultation and let engineering excellence drive your victory circle. 🏁