The Revolution of Visual Sales: Exploring Custom 3D Printed Displays

In today’s competitive retail environment, attracting audiences depends on innovative visual storytelling. Custom 3D printed displays are rapidly changing how brands present products, blending art with functionality and creating an immersive customer experience. Unlike traditional manufacturing, 3D printing unlocks unprecedented design freedoms, making the display as unique as their standout products. At Greatlight, we pioneered this revolution by leveraging cutting-edge revolution Selective laser melting (SLM) Turn the concept of vision into a technology for tangible brand reporting.

Why 3D printing Reigns to Supreme is used for custom display

Traditional display manufacturing (such as injection molding or CNC machining) often involves significant upfront costs, extended lead times and design compromises. 3D printing eliminates these obstacles:

- Unlimited creativity: Design complex geometric shapes, organic shapes or lightweight lattice structures using conventional methods.

- Quick iteration: Prototyping, testing and refining units in a few days rather than months.

- Cost Efficiency: Eliminate tool fees; ideal for small batches or one-time masterpieces.

- Sustainability: Reduce material waste through additive manufacturing (layer-by-layer structure).

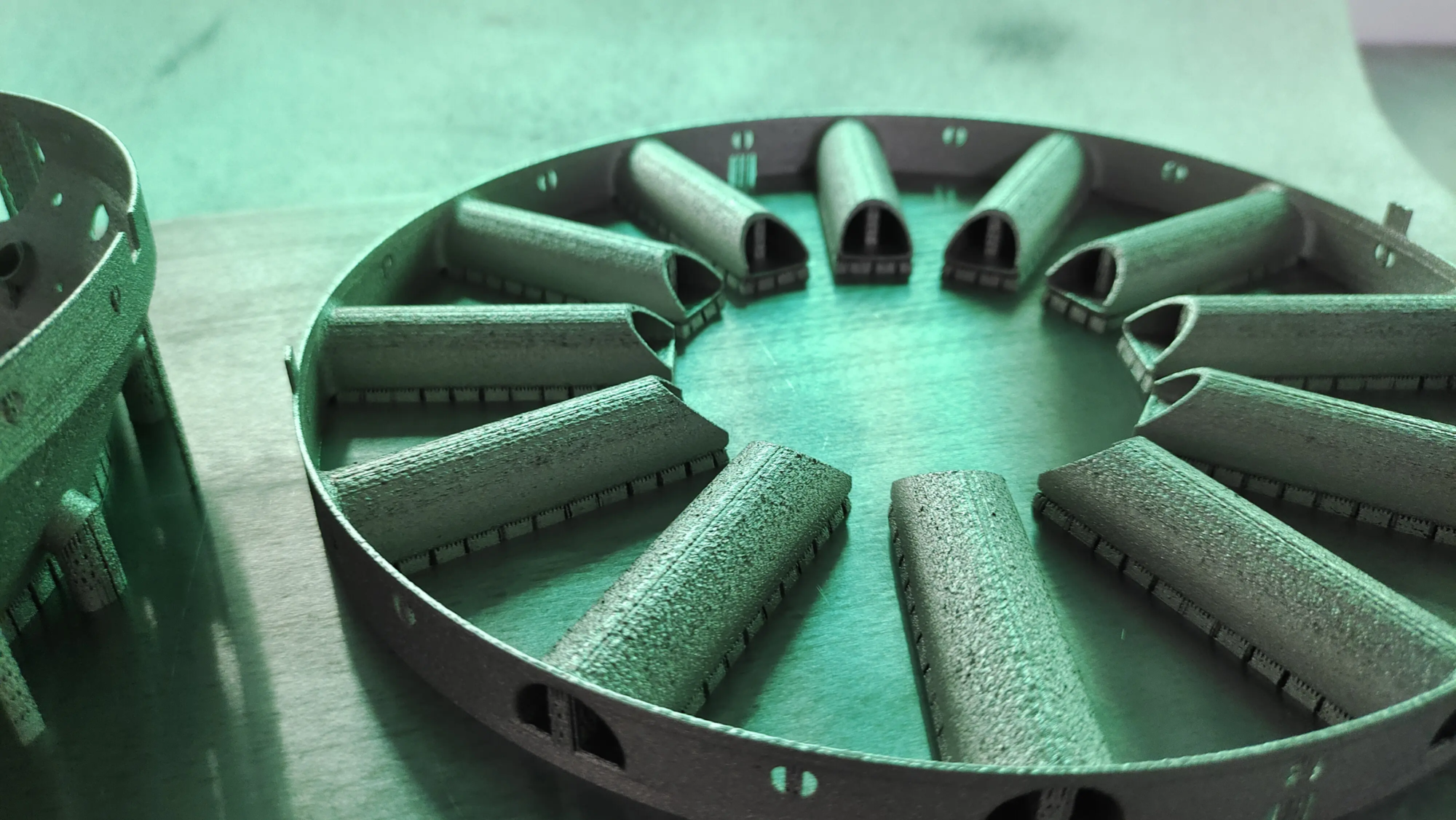

Technical advantages of Gre’s large agent: accurate and artistic

As a leader in rapid prototyping, Greatlight uses industrial-grade SLM 3D printers to manufacture metal displays with microscopic precision. SLM uses high-power lasers to fuse fine metal powders (such as aluminum, stainless steel, or titanium) to create dense, durable components layer by layer. It’s not just printing – it’s Engineering Art.

Our end-to-end process:

- Co-create: Work with our design team to optimize your 3D printing concept.

- Material selection: Choose from metals, polymers or composites and can be customized for strength, weight or finish.

- print: SLM ensures structural integrity even for ultra-thin walls or interlocking parts.

- Post-processing: Our one-stop service includes pressure relief, CNC finishes, polishing, electroplating, powder coating or custom textures.

result? Displays can be used extensively in high-traffic retail environments while reflecting the aesthetics of the brand.

Transformative applications across industries

- Retail and Luxury: Customized perfume stand with intricate filaments or jewelry holders of interactive kiosks.

- car: Showroom model for engine or light aerodynamic components.

- Technology and Exhibition: Ergonomic VR headphone rack, trade show booth with recessed lighting.

- Museums and Arts: Sculpture base for workpieces or avant-garde installations.

Why Greatlight stands out

While many offer 3D printing, Greatlight redefines excellence:

- SLM specialization: Our advanced printers handle complex high-load structures.

- Material mastery: Prototype or any product from aero alloys to biodegradable polymers.

- Fast Market: Accelerate production cycle (the initial prototype has a speed of 72 hours).

- Price performance: Competitive pricing without sacrificing metrological precision.

- Global Trust: Fortune 500 brand trust for mission-critical and end-use.

in conclusion

Custom 3D printed displays are no longer a futuristic concept, but rather a ROI-powered engagement tool. By combining aesthetic innovation with structural flexibility, brands can create immersive narratives that resonate deeply with consumers. Greatlight empowers this transformation, providing partnerships that not only provide manufacturing but also art, engineering and business intersections. From the initial sketch to the final polish, we make sure your display is not visible – remembered.

Ready to reinvent your visual logo? Work with leaders. Contact Greatlight now for design consultation and project quotations.

FAQs about custom 3D printing displays

Q1: How is a daily retail monitor durable for 3D printed monitors?

A: When manufacturing metals such as stainless steel or aluminum alloys are made through SLM, the parts traditionally processed by competitors will be displayed in strength. Post-treatment (e.g., heat treatment, coating) further enhances the wear resistance of long-term durability.

Q2: Can I print a multi-matter monitor?

Answer: Yes! Greatlight combines the process of creating a hybrid display (e.g., metal bases with polymer decoration). Discuss requirements with our engineers to optimize functionality.

Q3: What is the advance time for custom display?

Answer: The prototype will be shipped within 3-7 days. Production schedule depends on complexity – usually 2-4 weeks. Provide urgently needed services.

Q4: Is there a size limit?

A: Our SLM printer handles can reach up to 500×280×360 mm. Split the larger structure and then use interlocking joints or bonds for precise assembly.

Question 5: How cost-effective is 3D printing and quality production?

A: For low to medium volume or highly complex designs, 3D printing can greatly reduce costs by avoiding molds/tools. We scale pricing on competitive scale of bulk orders.

Q6: Which file format do you accept for design submission?

A: The preferred formats include .step, .iges or .stl. Our team guides you to the best results with file optimization.

Q7: Can the display contain electronic devices (e.g., LED lighting)?

Answer: Absolute. We design compartments for wiring and components and can integrate conductive materials. Post-treatment includes a finish to avoid interference.

Question 8: Is Greatlight on a global scale?

A: Yes – Our certified logistics partners provide strict quality inspections worldwide.

Get attention by precisely enhancing your brand universe. Explore endless possibilities with Greatlight’s custom 3D printed display.