Creating Perfect Sound: Your Guide to Custom 3D Printed Speaker Boxes

Have you ever felt limited by off-the-shelf car speakers? Striving to incorporate high-quality sound into an unusually shaped boat, motorcycle fairing, or custom furniture? Custom 3D printed speaker boxes are revolutionizing the world of audio integration, providing unparalleled freedom for achieving optimal acoustics and seamless aesthetics. This guide delves into why you need custom pods, how they are designed and manufactured, and the cutting-edge technology that makes them possible.

Why customize? Beyond One Size Fits All – None

Standard speaker enclosures utilize common spaces and mounting points – a rarity in custom vehicles, marine applications, architectural installations or high-end audio setups. This is the highlight of custom Pod:

- Perfect fit, perfect sound quality: Customized pods ensure the speakers are installed correctly within the precise space constraints of the vehicle or environment. This eliminates buzz, rattle and ensures the speaker operates within the optimal volume range for superior sound reproduction (bass response, clarity, staging).

- Maximize limited space: The pod effectively utilizes every nook and cranny to deliver high-quality audio in vehicles with limited space, such as sports cars or motorcycles.

- Enhanced acoustics and imaging: Pods can be designed to point the drivers precisely towards the listener, improving sound staging and imaging – crucial for an immersive experience.

- Seamless aesthetics: The one-piece design allows the pod to blend seamlessly with interior curves or exterior moldings, making it look like it was factory installed rather than added as an afterthought.

- Material mastery: Selecting materials optimized for strength, damping and dimensional stability allows the pod itself to act as a superior acoustic element rather than just a mounting bracket.

Core Allies: Advanced 3D Printing and Rapid Prototyping

Creating complex, acoustically tuned shapes to fit precisely into irregular spaces is a bottleneck in traditional manufacturing. This is the domain rapid prototypingspecifically Metal 3D printingenabling the creation of custom speaker pods that were previously impossible or prohibitively expensive.

- Free form: 3D printing (additive manufacturing) builds parts layer by layer directly from the CAD model. There are almost no geometric constraints. Complex internal bracing stiffness, optimized bass-reflex design port channels, complex organic shapes that follow the contours of the vehicle—all this becomes possible.

- Iterate quickly: Prototyping is critical for acoustics. Rapidly printing multiple iterations allows engineers to test the fit, structural integrity, and most importantly the sound quality (frequency response, resonance points) of different pod designs before going into final production. Rapid prototyping greatly shortens the design-to-function cycle.

- Unified complexity: Components that require assembly from multiple traditionally manufactured parts can often be printed as a single solid unit, reducing potential points of failure and assembly time.

Materials matter: building sound and intensity

Choosing the right material is crucial. Requirements include structural rigidity (to minimize vibrational deformations), dimensional stability (to prevent warping), damping properties (to absorb unwanted resonances), and sometimes thermal resistance. Common choices include:

- Advanced Polymers: High-performance engineering plastics such as polyamide (nylon PA12/PA11 – usually glass-filled PA-GF), PEEK or ULTEM® have excellent strength-to-weight ratio and good damping. Ideal for passenger vehicles or marine environments.

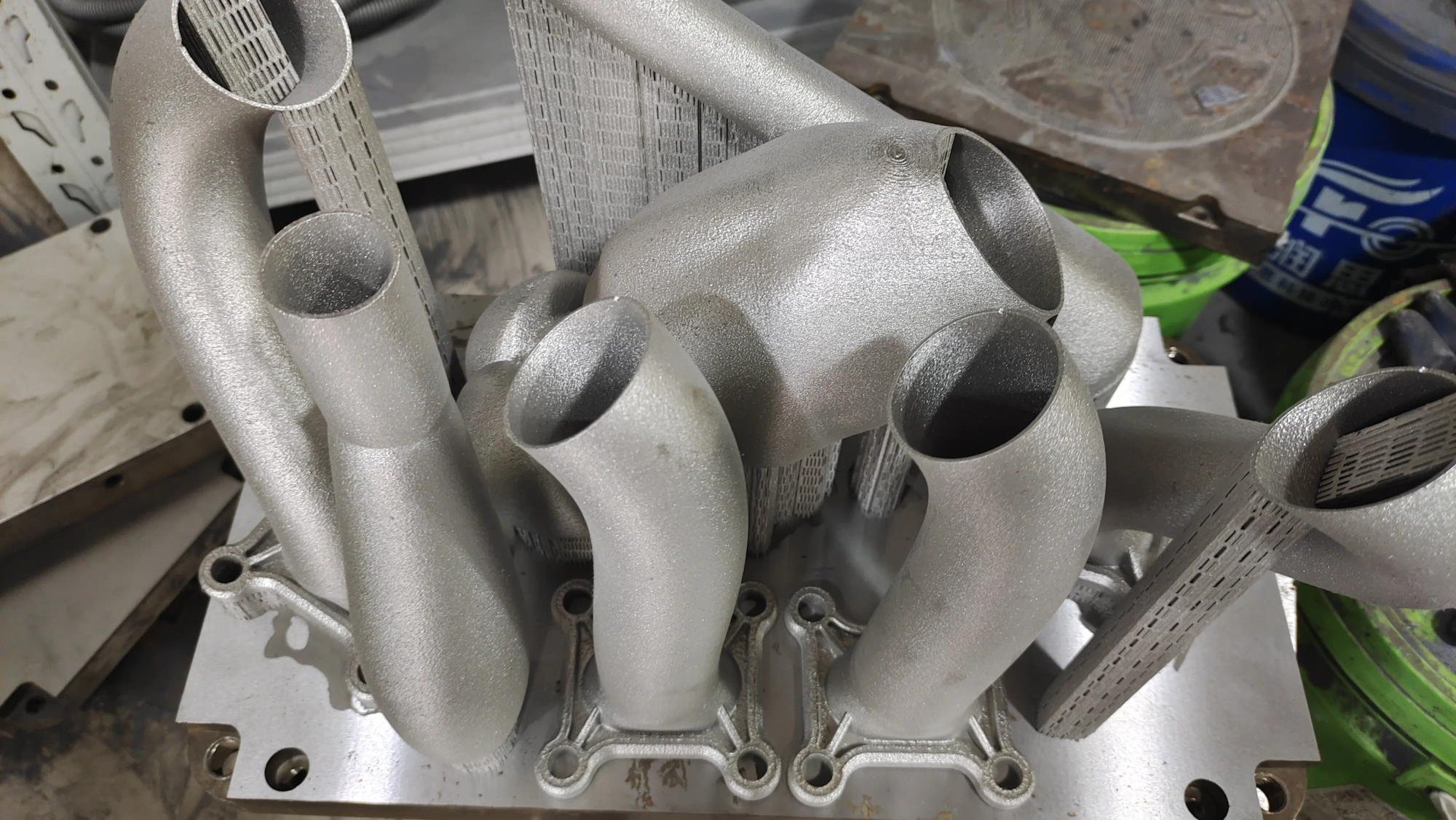

- Metal: Metal 3D printing shines when ultimate rigidity, heat resistance or integration with metal structures is required. where is this Selective Laser Melting (SLM) The technology is outstanding.

SLM: The power source of metal Pod

Selective Laser Melting (SLM) It is the premier metal 3D printing technology. It uses a high-power laser to fully melt fine metal powder layer by layer, fusing it into fully dense, complex metal parts.

- Why use SLM for speakers?

- Excellent strength and stiffness: The metal pods are extremely stiff and provide the speakers with a rock-solid mounting base, minimizing unwanted cabinet vibrations that can affect the sound.

- Precision and detail: SLM achieves outstanding dimensional accuracy and fine detail reproduction, which is critical for tight tolerances on mounting surfaces, port shapes and integrated features.

- Excellent thermal management: Metal dissipates heat more efficiently than plastic, which is beneficial in high-power speaker setups or environments such as engine rooms or marine applications.

- Material Versatility: SLM works on a wide range of high performance alloys: aluminum (AlSi10Mg – light and strong), stainless steel (corrosion resistant), titanium (high strength/weight), etc. This allows material selection to be optimized for specific environments and performance needs (for example, marine-grade aluminum for corrosion resistance).

- Ideal applications: Think high-end automotive show vehicles, demanding industrial audio monitors, motorcycle/integrated custom bike audio, marine applications requiring ruggedness and corrosion resistance, or situations requiring extreme heat resistance near the engine.

From Idea to Immersion: The Custom Pod Creation Process

- Design and CAD modeling: Work with designers/engineers. The detailed CAD model included precise measurements of the mounting location, speaker specifications (mounting points, magnet size, required enclosure volume), acoustic targets (seals, ports?), throat adapters, and desired aesthetics. Software simulations can predict vibration patterns and acoustic performance.

- Prototyping (iterative refinement): Initial prototypes are typically printed via SLS/SLA using cost-effective nylon or resin for initial shape/fit testing. Rigorously test fit. Subsequently, "tuning" The prototype focuses on acoustic performance and structural refinement under vibration/pressure. Metal prototyping via SLM may occur late in the process for critical metal parts.

- Material selection and final design lock-in: Based on the prototyping results and application requirements, the materials (SLM metals vs. high-performance polymers) are finalized. Improve the CAD model.

- Additive Manufacturing: Print the final Pod using the industrial AM technology of choice (SLM for metal, SLS/SLA/MJF for polymer).

- Post-processing and finishing: Basic steps to meet final specifications:

- Metal (SLM): Removal from build plate, heat treatment (stress relief, aging), CNC machining of precision mounting surfaces (if required), surface finishing (sandblasting, polishing, powder coating, anodizing).

- polymer: Supports removal, sandblasting, smoothing/coating, staining, and painting. Critical damping materials may be applied to the interior.

- Quality Verification: Precise metrology (CMM scanning) ensures dimensional accuracy, pressure testing (for closed designs), rigorous final FIT inspection.

Why choose GreatLight as your custom Pod partner?

Achieving world-class custom speaker pods requires deep expertise in acoustic engineering and advanced manufacturing. huge light Stand out as a leader Rapid prototyping and precision metal additive manufacturing solutions. That’s why we are your partner for your most demanding audio integration projects:

- Industrial grade metal craftsmanship: We operate advanced SLM 3D printerallowing us to produce structurally superior, complex metal speaker pods from strong alloys such as aluminum, stainless steel and titanium, which are critical for challenging environments and peak acoustic performance.

- End-to-end engineering support: We don’t just print documents. Our team works closely with your design team to provide materials science and DFAM (Design for Additive Manufacturing) insights to optimize your pod structure, acoustics and manufacturability.

- Comprehensive prototyping expertise: Speed is of the essence. We specialize in rapid iterative prototyping (functional polymers and metals) to validate designs and acoustics more quickly, significantly reducing your project time.

- Unparalleled post-processing: Our one-stop service includes advanced post-processing capabilities. For SLM pods, this means precision CNC machining of critical interfaces, along with heat treatment and high-quality finishing (powder coating, anodizing, polishing) to achieve perfect functionality and required aesthetics.

- Material flexibility: From specialized high-performance polymers suitable for interior integration to high-strength, heat/corrosion-resistant metal alloys, we provide expert guidance and processing of virtually any material needed to meet the unique needs of your speaker box.

- Precision core: Our foundation in precision machining translates into meticulous attention to tolerances and final quality control, ensuring every Pod operates flawlessly and integrates seamlessly.

- Dedicated partners: We understand that audio applications require passion and precision. We collaborate as an extension of your development team, dedicated to efficiently and effectively turning your vision of flawless sound integration into reality.

- Cost-effective innovation: Using additive manufacturing optimization, we can often reduce the cost of complex geometries compared to traditional methods, providing a high-quality solution at a competitive price.

in conclusion

Custom 3D printed speaker pods represent the pinnacle of custom audio integration. They unlock acoustic potential that traditional solutions fall short of, ensuring flawless fit, optimized performance and stunning aesthetics. While the shell may appear simple, the entire process from concept to finished pod utilizes complex design, rigorous prototyping, advanced additive manufacturing (particularly critical metal-based SLM) and meticulous finishing.

Select a manufacturing partner with deep rapid prototyping expertise, industrial metal additive manufacturing capabilities (such as SLM), and a commitment to engineering partnerships (such as huge light – is the most important. This ensures that your custom pod not only integrates perfectly, but delivers the accuracy, intensity, vibration control and acoustic fidelity required for truly superior sound.

Ready to elevate your audio with perfectly customized speaker pods? Skip limitations and embrace customized soundscapes.

FAQ (Frequently Asked Questions)

Question 1: Which speaker pods would benefit most from metal 3D printing (SLM)?

A: SLM is ideal for applications requiring extreme stiffness and heat/corrosion resistance: high power car audio near engines/turbines, marine/boating environments, exposed motorcycle pods, industrial/power sports equipment, custom outdoor installations, and high-end reference monitors requiring absolute box stability.

Q2: Are plastic printed cigarette cartridges strong enough?

Answer: Of course. Advanced engineering polymers, specifically glass/natural fiber filled polymers (PA-GF, PA-CF), provide superior strength, stiffness and damping. They are generally ideal for most automotive interiors, studios and home audio installations. SLS/SLA/MJF technology produces strong, functional plastic parts.

Q3: How much does the design process cost?

A: Costs vary widely based on complexity, prototyping iterations required, material selection, and manufacturing volume. Simple pods may be economical to start with, whereas complex metal pods that require extensive acoustic testing/prototyping will cost more. GreatLight provides advance quotes based on CAD models or specifications.

Q4: Can I design the pod by myself?

A: While technically possible, acoustic enclosure design requires expertise. Effective Pods integrate driver specifications (Thiele/Small parameters of enclosure volume/port), accurate spatial modeling, vibration analysis and DFTM. It is highly recommended to work with an experienced engineer or a company that specializes in audio integration. GreatLight provides collaborative engineering support.

Q5: How long does it take to customize a cigarette cartridge?

A: Timeframe depends on design complexity, prototyping stages required, material selection and finishing requirements. generally:

- Design/prototyping phase: 1-5 weeks.

- Manufacturing/Finishing: 1-4 weeks.

SLM production/heat treatment cycles for metal parts can be longer than for plastic parts. GreatLight’s rapid prototyping significantly speeds up timelines.

Q6: Does GreatLight handle both interior and exterior finishes?

Answer: Yes. We offer a wide range of surface treatments: Sanding, Sandblasting, Tinting/Staining, Professional Painting, Plastic Texture Coating. For SLM metals: fine machining, heat treatment, grinding/polishing, powder coating, electroplating (nickel, chromium), anodizing (especially aluminum) as required.

Q7: Are you producing more pods than the prototype?

Answer: Of course. Although excluding