The Dawn of Custom GI Joe Collectibles: Unleashing Heroes through 3D Printing

Remember the excitement of opening a new G.I. Joe action figure as a kid? For decades, these iconic figures have symbolized heroism and adventure. But what if your Cobra Commander could wield a custom laser cannon, or Duke’s armor could be redesigned with intricate sci-fi details? that’s there 3D printing Transform nostalgia into limitless creativity. I’m taking a deep dive into how this technology could revolutionize Spec Ops customization, combining fandom with cutting-edge manufacturing—especially through things like glow rapid prototyping.

Why 3D printing could be a game-changer for ‘G.I. Joe’ fans

Traditional puppet customization relies on sculpting clay or assembling existing parts—a time-consuming process with mixed results. Now, 3D printing allows collectors to:

- Design custom parts: From robotic limbs to period-accurate military equipment, there are never-before-released characters.

- Achieve military-grade accuracy: Perfectly reproduce intricate details such as helmet visors or weapon textures.

- mixed materials: Plastic body Metal reinforcement materials (for example, joints or weapons) for durability and realism.

Behind the Scenes: How technology like SLM improves custom data

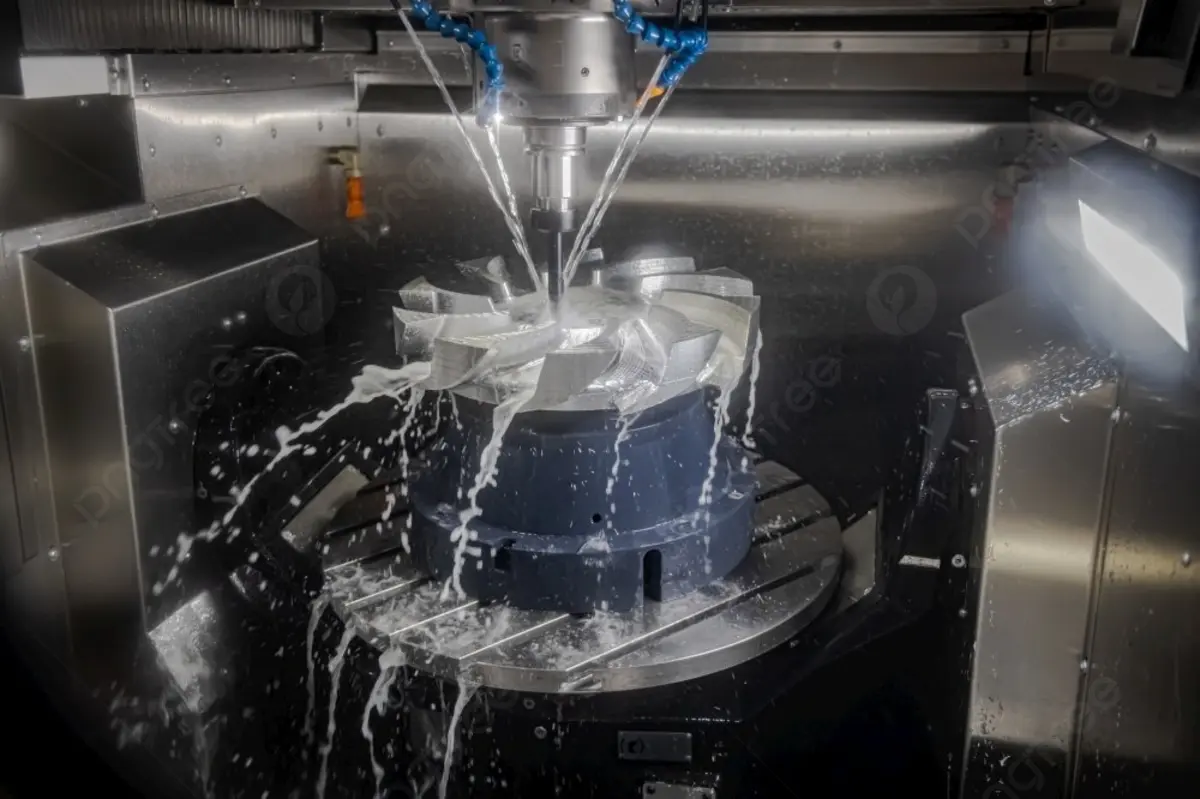

Although hobbyist 3D printers process plastic, metal parts It is the highlight of professional services. This is critical for functional parts like articulating knees or monitor bases. company likes huge light Leverage Selective Laser Melting (SLM) technology:

- Print durable metal alloys: Stainless steel, titanium or aluminum parts can withstand wear and withstand stress.

- Ensure microscopic precision: SLM’s laser precision enables up to ±0.025mmcrucial for interlocking components.

- Supports complex geometries:Create hollow structures or internal channels not possible by molding (for example, for connecting LED eyes).

In my own projects, I’ve found that plastic joints fail when frequently posed. Reinforce them with GreatLight 420 stainless steel part? It’s been a lifesaver for my collection.

Your workflow: from concept to battle-ready hero

- design: Use CAD software such as Blender or SolidWorks or collaborate with a digital artist. Share files in STL/OBJ format.

- Material selection: choose Nylon plastic For lightweight bodies or metal alloy For use in highly stressed components.

- Printing and post-processing: This is how important GreatLight’s end-to-end expertise is:

- SLM printing Used for metal strength.

- Grinding, polishing or electroplating Decorate your showroom.

- Painting/Coating: UV resistant layer prevents toy display from fading.

- assembly: Put together the upgraded GI Joe, now a one-of-a-kind masterpiece.

Professional advantage: Why GreatLight can provide products that DIY is not enough

While desktop printers are fine for prototyping, production Exhibition grade collectibles Industrial power is needed. Gretel’s outstanding features are:

- Solve unique challenges: Design that is easily deformed? Their thermally controlled SLM printer prevents distortion.

- Provide full material customization: From flexible TPU for capes to chrome-plated steel for decoration.

only - One-stop post-processing: Parts are hand-finished for ease of assembly.

their quick turnaround rapid prototyping Service means you can quickly test iterations, which is crucial to finalizing Baroness’ complex eyepiece designs!

Real World Impact: Case Studies

Imagine customizing one "Steel Brigade" Soldiers equipped with metal exoskeletons. Using GreatLight’s Hil service:

- The titanium chest plate is printed via SLM 0.03 mm resolution.

- Post-processed by sandblasting to give a matte military texture.

- Seamlessly integrates with 3D printed plastic limbs.

The result? Museum-quality piece survives drop test from 3 feet.

Conclusion: The future of fandom is in your hands

3D printing transforms the G.I. Joe collection from passive ownership to active creation. Work with professional partners like huge lighteven the most ambitious designs – whether in plastic, religious metal or mixed materials – become achievable. their fusion Advanced SLM technologymaterial versatility and finishing expertise ensure your custom hero isn’t just built; it’s engineered to last. Ready to design your elite lineup? The battlefield awaits you.