Forge Your Own Lorrain: The Ultimate Dark Soul 3D Printing and Finishing Guide

The world of Dark Souls greets with its haunting beauty, intricate armor and legendary weapons. For countless fans, the desire to have a part of this iconic universe – the great swordsmanship of wielding Artorias or the compliment of the Solaire’s Solaire – is a powerful attraction. Thanks to modern technology, this dream can be realized. 3D printing has revolutionized the production of props and models, making defilements everywhere physically show artifacts of Lorain, drangleic and lothric. But the journey from digital files to the props worthy of display requires knowledge and skills. This guide is your Estus flask.

Crucible: From Digital Models to Physical Reality

-

Procurement Blueprint (STL file):

- Hunting begins: Treasures exist on platforms such as The Thingiverse, Cults3D, Myminifactory and dedicated Patreon creators. Search terms similar "Dark Soul Weapon STL," "Dark soul boss statue," "[Character Name] Armor STL" Produce rich results.

- Quality Review: Not all files are created equally. Check photos, comments (if any), and find details such as:

- Manifold (watertight) grid: Make sure the model is firm without holes or errors confusing the printer.

- scale: Is it pre-sizeable? If not, you will need to rescalate the skills.

- Including support? Some creators provide pre-supported files that greatly simplify printing settings.

- Level of details: Does it capture the complex prints and conform to the authentic weathering of the artistic nature from Software?

- Business and Personal: Strictly comply with the licensing terms. If the creator sells the documents, please buy it! Never use tear-out game assets for commercial sales – only your own personal projects.

- Choose your printing technology ( "how"):

- FDM (Function Deposition Modeling – Filigree):

- advantage: For large items, easy-to-get printers/materials, suitable for strong functional parts of armored plating or sturdy weapon cores.

- shortcoming: The visible layer lines require a lot of post-processing, lower resolutions to get details (chain mail, small prints), and distort risk on large prints.

- Ideal: Large armor pieces (helmet, breastplate, shield), sturdy weapon handle/blade, diorama terrain/building block. Materials: PLA (simplest, stiff), PETG (sturdier, more flexible), ABS/ASA (heat resistance, smoother, but requires a shell).

- SLA/DLP/MSLA (resin printing):

- advantage: Excellent surface resolution and detail capture – Great for characters, intricate jewelry, decorative parts, small arms/hilts, faces. The smallest visible layer.

- shortcoming: The resin can be fragile (not ideal for functional props), is more expensive per roll and requires careful treatment (toxic unfixed resin), and post-treatment includes washing/UV curing, and parts are usually smaller than FDM.

- Ideal: Boss/Miniature characters, character bust, detailed rings/amulets (Havel’s Ring!), intricate weapon embellishments, small props (Darksign, Estus Flask). Materials: Standard resin (brittle, details), similar to ABS-like resin (sturdier), flexible resin (for cloth effect).

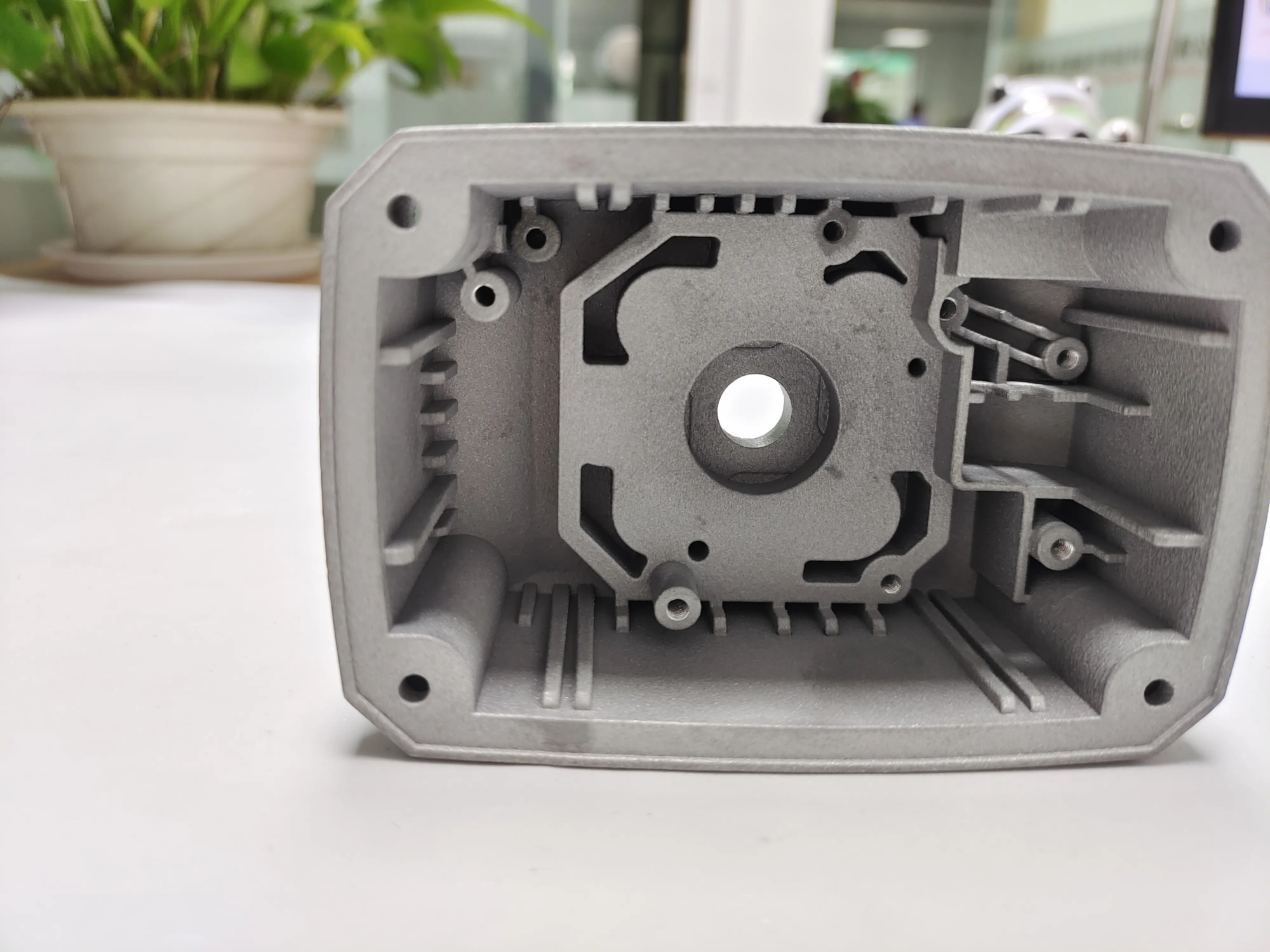

- Professional metal printing (Selected by Advanced Master – SLM): Selective laser melting (SLM) is the pinnacle when maximum intensity, metal authenticity and unparalleled details are needed, especially for extremely complex microscopic or surreal small arms.

- advantage: Generate solid metal parts (stainless steel, titanium, aluminum alloy) with incredible density and mechanical strength. Difficulty in implementing detailed information other processes. The result is inherently durable and feels real.

- shortcoming: High costs often require professional services such as Greatight rapid prototyping, which requires limited build sizes per machine compared to large FDMs (and requires professional sintering/post-processing).

- Ideal: Museum – Quality replicas of famous weapons, super detailed miniature battle scenes, custom jewelry/challenge medals, made of metal, functional height armor joints/buckles, scenes, demanding unique characteristics of metal. That’s where Greatlight’s expertise lies.

- FDM (Function Deposition Modeling – Filigree):

The Art of Blacksmith: Post-processing Perfection

The original version is similar to the burned undead; the post-processing makes them ignite like a bonfire to make them live.

-

Cleaning and Preparation:

- FDM: Carefully remove the support (flush cutter, pliers), and the sand parts start to rough (80-120 particle size) and move to finer gravel (220, 400+). Fill the layer/gap with fill putty, the sand is smooth.

- Resin: Wash thoroughly in an IPA (or a dedicated washing station). Completely cured under ultraviolet light. Carefully remove the support, sand/fine noodles.

* Metal (SLM): *Requires professional treatment. Greatlight provides vital post-treatment, such as stress relief annealing, removal of support structures by precise CNC milling or EDM, and surface completion by tumbling, polishing, bead blasting or special coatings. It may also be necessary to process critical mating surfaces.

-

assembly: For multi-part prints, use strong glue (epoxy, super glue or UV resin for FDM), pins (brass rods), or magnets for articulation (armor joint). Ensure accurate alignment.

- Prime & Paint: Prime (Filling Primers are great for FDM) produce a uniform surface. Patience is the key. To realize the aesthetics of dark souls, you need to master the painting techniques:

- Basic jacket: Put down the original color.

- Wash/Ink: Dark brown/black washing depressions create momentary depth and shadows.

- Dry brush: Gently brush light colors on the raised surface for wear and highlighting.

- weathering: Sponge debris (coating paint for metal debris), rust effect using special paint or pigment, mud/dirt splash. Reference game screenshots continue!

- seal: Protect your masterpiece with a matte, satin or glossy sheer jacket (varnish).

When Dreams Need Metal: Working with SLM Masterpiece

For many dark soul artifacts, especially iconic weapons or works envisioned with real metal, enthusiasts prints hit the wall. accomplish:

- weight: The true weight and feel of solid steel or titanium.

- Complexity: Capture tiny engravings with rings or blade inscriptions on a high-fidelity mini scale, which may be structurally plagued by it.

- Final Power: Functional props are durable, designed to last forever display or demanding applications.

- Metal finish foundation: Starting with real metal means achieving Patinas, thermal melting or mirror polishing is more convincing.

This is where Greatbight quickly prototypes enter competition. As a professional rapid prototype manufacturer Advanced SLM 3D printing technologyWe transform your highest dark soul STL file into amazing metal reality.

- Consultation and optimization: We work with you to analyze models, discuss material choices (stainless steel affordability and durability, aluminum alloys for lightweight strength, ultimate reputation for titanium), and ensure manufacturing – providing advice on wall thickness, detail fidelity and orientation.

- Precision SLM printing: Our industrial grade SLM printers use high-power lasers to selectively fuse fine metal powder layers in an inert atmosphere to create complex dark soul artifacts with extremely high accuracy and density, even on geometrically complex items such as geometrically complex items such as hovering swords or dancer’s Regalia.

- Professional post-processing expertise: This is very important. Our One-stop service deal with:

- Careful support structure removal without damaging delicate features.

- Relieve stress to ensure partial stability.

- Complete finishing range: from smooth media blasting and hand polishing to critical CNC machining for precision.

- Options for dedicated coatings (custom plating, anodizing) for specific appearances. We have taken complicated and dangerous steps from your hands.

- Materials and speed capability: Need a cinder replica in heat-resistant inconel? Or dream of using ilmenite ornaments in actual titanium? We provide A wide range of materials and custom solutions,deal with fast Thanks to our expertise and productivity.

Conclusion: Ignite your creation

3D printing unlocks the realm of dark souls, allowing you to fake legends on the screen. Amateur FDM and resin technology enhance incredible creativity, bringing the world to life through careful machining and artistic painting. For demanding unparalleled authenticity, structural integrity, complex details captured with real metals or pure reputation for possessing solid metal relics, the sheer reputation of professional SLM 3D printing becomes crucial.

This is a great field. We merge Advanced SLM equipment, deep production expertise in sintering parameters and metallurgy, and comprehensive post-processing functions Solve complex rapid prototyping challenges – transform your vision of the most ambitious dark soul into a breathtaking metal masterpiece. Whether it’s a small, exquisite ring or a powerful giant ring with size for display, our focus is on providing precision, quality and speed at the best value.

Are you ready to lift the passion project of Dark Soul from filaments or resin to unparalleled metal craftsmanship? Greglight is ready in your forging. Let us help you create something truly legendary.

FAQ: Dark Soul 3D Printing and Metal Prototyping

Q1: Where to find the best place to find high-quality Dark Souls STL files?

A: Famous markets include Thingiverse, Cults3D, Myminifactory and Patreon creators, specializing in gaming STL. Prioritize creators, with good reviews/previews and clear licensing terms.

Q2: I printed the helmet (FDM), but the layer line is terrible! How can I solve it?

Answer: Post-processing is the key! Thorough sand starts from coarse sand and develops into finer gravel (400+). Apply the fill primer and dot putty in the gap and sand again. Multiple primer cycles produce the smoothest surface. Embrace the challenge!

Q3: My resin-printed Knight Artorias statue broke on the sword (!). Which resin is best for numbers?

A: The standard resin is very brittle. Rescue attempts: Try to fix the rest with a small drill bit and bonded brass rod. Future printing: use "Similar to abdominal muscles" or "Tough" Resin with significantly higher impact on resistance and flexibility is perfect for thin parts such as weapon blades. Greglight’s SLM Metal is the ultimate solution that cannot break the micro.

Question 4: Can I print Real Metal dark soul armor?

A: It is not feasible to print out armor with a fully wearable board directly. However:

- replica Parts (Pauldrons, Gauntlets, buckles) for display: Greatlight’s SLM service is absolutely possible.

- Functional wearable armor: Usually involves printing molds (FDM) and cast in resin/fiber glass, or using printed parts as the core reinforced with foam, fiberglass. High-end commissions may be metal plating via electric type or professional SLM fragments.

Question 5: I want a miniature Artorias Greatsword, but it looks fragile in the resin. Is there any choice?

Answer: For Extreme microscopes that require strength and detailgreat SLM technology is the main solution. We can print out incredibly complex little swords (1:6, 1:10 ratios, and even smaller) with solid stainless steel or aluminum, capturing every detail of the twisted metal and crests while making it nearly indestructible. This bypasses the brittleness limitation of the resin.

Question 6: How much does it cost to get a professionally printed Dark Souls Replica metal?

A: The cost varies greatly based on complexity, size, metal material selected (titanium>stainless steel>aluminum), the required finish and quantity. SLM is usually more expensive than filament/resin-loving printing, but produces unique heirloom quality works. Contact your model files directly with Greatlight and accurate quote requirements – We focus on providing the best quality in competitive rapid prototype pricing. Small detailed items can be done surprisingly.

Question 7: Can Greatlight handle painting and final assembly?

A: Our core expertise is Precision metal 3D printing and professional post-processing/complete (grinding, polishing, blasting, coating (such as plating/anode)). We usually provide original metal components. For complex painting and assembly of complex multi-part props, you may need a professional model or prop painter (depending on the scope of the project). We can provide suggestions based on your needs!

Q8: Can metal parts be safely handled/weared?

A: Parts produced by SLM and parts made by Greatlight are safe solid metal objects. However:

- We recommend you to be bored with any Very sharp spot Unless otherwise specified to show, intentional (e.g., weapon prompts) are safe.

- Once the post-processing is smooth, wearable pieces (such as brooches or buttons) are inherently safe metal. Weight is a key consideration for larger wearable devices.