Unlocking Flexibility: A Comprehensive Guide to Designing a 3D Printed Life Hinge

Living hinges – those clever, bendable connections carved from a piece of material – engineered miracles in injected plastic. Think of a snapshot cap on a tomato bottle or a flexible toolbox compartment. Traditionally, the emergence of 3D printing is now limited to mass production, and now allows designers to directly produce functional living hinges with unprecedented speed and flexibility. However, mastering the life hinges of 3D printing requires going beyond traditional design rules. Let’s dig deep into the complexity of designing these flexible functions for successful additive manufacturing.

Why 3D printed life hinges? Advantages

- Integrated design: Eliminate assembly steps, reduce part counting, and minimize fault points (pins, bearings) associated with traditional hinges.

- Rapid prototyping: Iterative hinges are designed to be fast and cost-effective without the need for expensive tools.

- Complex geometric shapes: Creating hinges on complex non-planar surfaces is difficult or impossible in molding.

- Lightweight: Save a lot of weight by integrating the hinges into the part structure.

- Custom: Designed custom hinges feature unique flexible patterns, strength and a custom-made beginning for specific applications.

Design for success: Main considerations

-

Thickness is crucial: This is the most critical factor.

- Find a sweet spot: Typically, the hinge thickness is from 0.2mm to 0.5mm For common materials such as PLA, PETG, nylon and PP. Thicker speeds greatly reduce flexibility and increase pressure; thinner risks can be fragile and print failure.

- Consistency is key: Maintain a consistent thickness throughout the hinge length. Avoid sudden changes or bulges.

-

Hinge length and width:

- length: Longer hinges usually allow greater deflection angles to better distribute pressure over larger areas. It is usually recommended that the minimum length is 6-10mm.

- width: The wider hinges are stronger, but require more force to bend. Ensure that the width is sufficient to handle the applied load without tearing.

-

Transition zone (bending):

- Avoid sharp corners: The sudden 90-degree bending acts as a stress concentrator. use Large, spacious fish slices (Radius of 1mm or more) The hinge conforms to the rigid part of the part.

- Taper transition: The thickness of the material from the hinge to the body gradually increases by several millimeters.

-

Flexible direction and layer direction:

- Printing direction is crucial: The hinge should always be printed Perpendicular to the building board (Stand upright). Placing it flat on the bed results in a layer line parallel to the bending direction, which is easily layered and malfunctioned after minimal buckling.

- Bending direction: Design hinge bent Along the layer linenot the other party. When parallel to the layer, the intensity is significantly higher.

- Geometric variation:

- Straight hinge: The simplest form, suitable for applications that require precise alignment.

- Wave/Double Stable Hinges: Can be merged "beach" (wavy) pattern or specific geometric shape to create "Break" Open/close position or make the hinge more forgiving during bending.

- strengthen: For high stress applications or softer materials, micropatterns (such as diamond lattices) in the hinge area able Sometimes, despite the added complexity, it can sometimes help distribute stress.

Material selection: the basis of performance

Not all 3D printed materials are created for the purpose of living hinges:

- Thermoplastics (FDM/FFF):

- PP (polypropylene): The gold standard. High flexibility, excellent fatigue resistance (can withstand 1000 seconds cycle). Printing is challenging (adhesion problem), but ideal if possible.

- Nylon (PA6, PA12): Strong, flexible and durable with a good fatigue life. Careful drying and temperature control are required.

- petg/co-polyesters: Good balance of flexibility, strength and easy printing. Better fatigue resistance than PLA, but less than PP/nylon. Ideal for prototypes and medium-purpose hinges.

- TPU/TPE (flexible filament): Not recommended for Living hinges. They are too soft and lack the necessary button or structural integrity required in traditional hinge movements. They are hinge components itself In flexible parts, not thin connections.

- PLA: Stiff and fragile. After only a few bending cycles, it is prone to rupture. Avoid using very low count prototypes.

- Resin (SLA/DLP):

- Hard/durable resin: Due to the higher elongation at rest, some resins (e.g., formlabs Tough, Siraya Tech Blu/Tenacion Blends) can achieve decent hinge performance. It is more fragile than FDM thermoplastics such as PP/nylon. Fatigue life is usually low.

- Standard and engineering resins: Usually too brittle to use functional hinges. Hinge failure (capture) may be possible.

Printing Tips and Post-Processing Secrets

- Best settings:

- Walls/arounds on the filler: Print hinges using exterior walls only – No filler, no upper/bottom layer. Use 3-4 circumferences to ensure strength.

- Layer height: The fine layer (0.1mm -0.15mm) improves layer bonding and surface finish, thereby reducing stress concentration.

- Print slowly: Reduce the printing speed of the hinge section to ensure accurate deposition and maximum layer adhesion.

- Retraction/exhaust control: It is crucial to prevent spots that damage thin structures. Carefully adjust the recycling settings.

- cool down: Maintain consistent and intense cooling (100% fan) to quickly solidify the layer and improve geometric stability.

- Key post-processing:

- Initial bending ("train"): Gently bend the hinge back and forth Immediately After printing (FDM is still slightly warm) to its final open/close position 5-10 times. This aligns the polymer chains and significantly improves fatigue life.

- Pressure relief (Annealing-FDM): For materials such as nylon or semi-crystalline plastics, controlled annealing can increase crystallinity and toughness, thereby improving hinge life. Follow the precise material guidelines due to the risk of shrinkage.

Application of 3D printing life hinges

- prototype: Feature prototypes of housing, clips, snapshots, foldable components, containers, consumer product concepts.

- Low-volume production: Custom enclosures, professional equipment coverings, packaging fixtures, auxiliary equipment, educational models.

- Wearable devices: Adjustable belt, latch mechanism.

- Robotics: Soft robot or flexible joints in handshake.

- Theme props and role-playing: Functional, lightweight clothing elements.

in conclusion

3D printed living hinges open exciting avenues for exciting pathways to integrated, lightweight and innovative designs. While challenging, successful measures (pun intended!) are meticulously focused on design principles (especially thickness, direction and transition) – plus careful material selection and dial-in printing setup and post-processing. By respecting the unique properties of additive manufacturing and selected materials, designers can leverage 3D printing to create durable functional hinges that simplify parts and unlock new possibilities.

Remember, prototyping is the key. Test the hinge iterative design, starting with standard parameters and adjusting according to material behavior and real-world bending performance. Embrace the challenge and bend the limits of possible!

FAQ: 3D printed life hinges

Q1: Can metal 3D printing (SLM/DML) produce living hinges?

A: Usually, no. Metal 3D printing essentially produces rigid brittle microstructures that are not suitable for repetitive, high-quality bending, which is required for life hinges. While designers sometimes explore compliance mechanisms with similar thin layers in metals, they are fundamentally different from plastic living hinges and require expert crack mechanics analysis.

Q2: My PLA hinge was snapped up immediately! How can I solve it?

Answer: The fragility of PLA is the core issue. First, try to significantly lower the hinge thickness toward the downward end (~0.25mm) and ensure a perfect printing direction (the hinge is vertical). More importantly, switch materials. Petg PLA with hinge flexibility and lifespan is very superior to PLA, while providing similar printing properties. nylon or pp Best for demanding applications.

Q3: Why is vertical printing hinges so critical?

Answer: When printing vertically:

- Layer line operation Parallel lines To the bending direction.

- Bending force pull Along The bond wire is attached to the layer, and the strength is higher.

- Bending force behavior when printing is flat Passed through These layers, separating them – leads to rapid stratification and failure (usually looking like skinning).

Question 4: How many elastic cycles can I expect from the 3D printed life hinge?

Answer: This is very different:

- PLA: Very low (usually <10 cycles).

- PETG: Moderate (dozens to hundreds of cycles with good design and "train").

- Nylon (PA): High (hundreds to low cycles).

- PP (polypropylene): Excellent (thousands to thousands, close to injection molding performance through optimized printing).

- Resin: Varies by specific resin, but usually hundreds of thousands to hundreds of "Tough" mix.

Q5: What is it "Double stability" Can living hinges be printed in 3D?

A: The double-stable hinges have two stable resting positions (usually open and closed), breaking them without an intermediate position. Yes, specific bends ("beach" Style) Design hinge design can achieve double-stable or over-center behavior through clever geometry and can be successfully printed in 3D. Prototyping for adjustments "Break".

Realize your vision with expert rapid prototyping

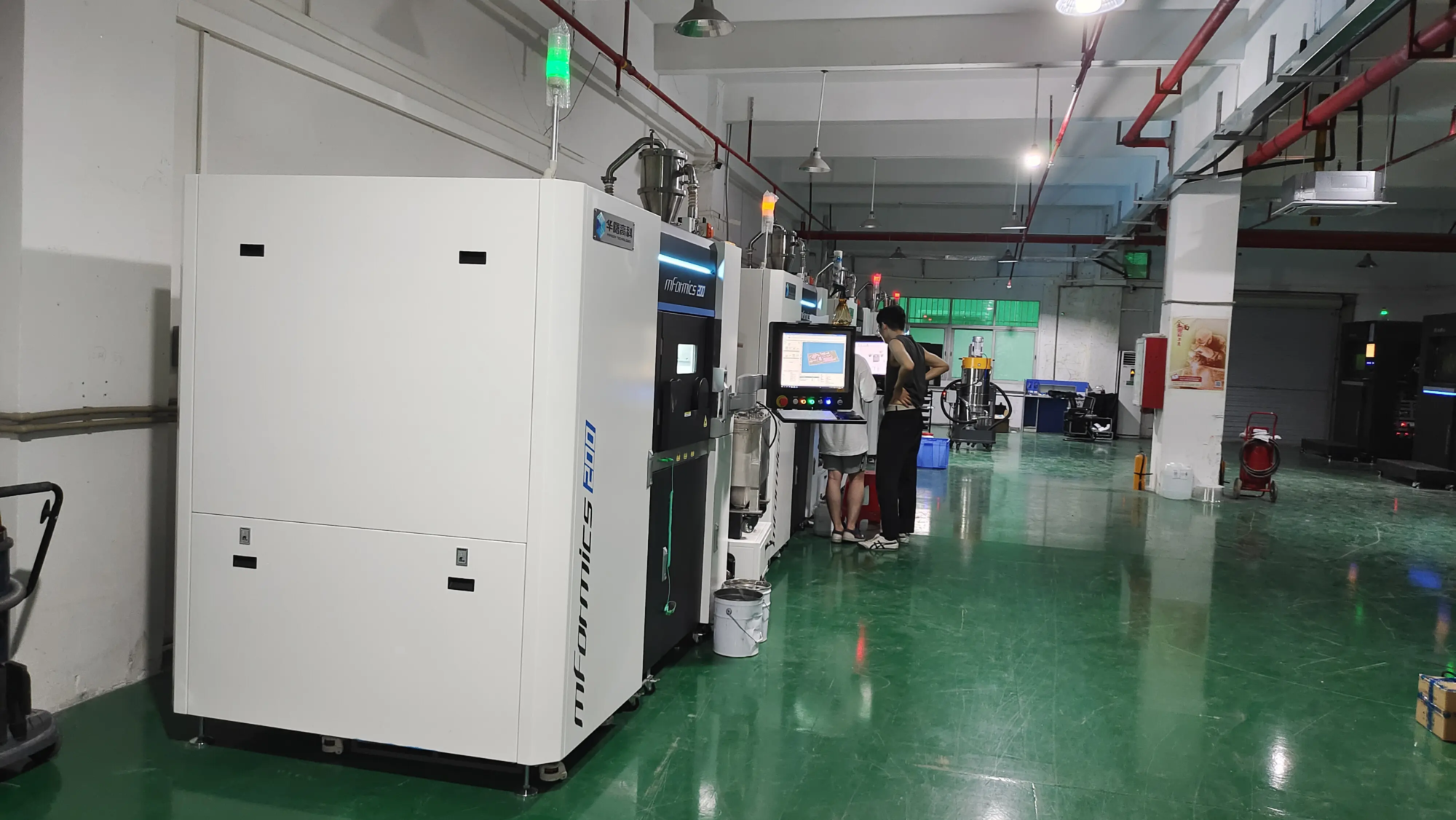

Designing complex functional parts such as living hinges pushes 3D printing capabilities to the limit. Success requires not only originality in design, but also excellent manufacturing. This is Great Good at it. As a leading professional rapid prototyping manufacturer, we combine:

- Advanced SLM technology: Precise metal additive manufacturing for reliable prototype and end-use parts.

- Industrial grade FDM and resin printing: Visit a wide range of engineering thermoplastics and Specialized materials are ideal for applications requiring elasticity, such as living hinges (PP, nylon, high performance resin).

- Expert design and DFAM support: Our engineers understand the nuances of designing for additive design, including living hinges, provide actionable feedback for optimal manufacturability and performance.

- Comprehensive post-processing: From the hinge "train" To remove expert support, finishes (sanding, smoothing, steam polishing), painting and assembly – we provide seamless one-stop solution.

- Speed and customization: Fast turnaround time on customizable parts regardless of complexity.

GRESTHILE: Your precise prototype partner. Stop using print settings and partial failure wrestling. Leverage our expertise to bring your innovative designs, including functional living hinges, from concept to reality, to speed, accuracy and reliability. Contact us today for a quote for your next custom Precision rapid prototyping project!