Enhance your workspace: Design a custom 3D headphone stand

In the world of personalized tech accessories, a custom headphone stand isn’t just functional, it’s also a statement. While mass-produced stands have cluttered the market, why not create a stand that suits your style, space, and headphones? Advances in 3D printing have made this combination of practicality and creativity within reach. Whether you’re a designer, audiophile or hobbyist, building your own exhibition stand blends engineering and art. Let’s explore how.

Why customize?

- Ergonomics and protection: Tailor-made design optimally supports the headphones, reducing pressure on the headband and earcups.

- space efficiency: Maximize desktop space for your setup.

- aesthetic expression: Match your decorating style – minimalist, futuristic or themed.

- cost control: Avoid premium retail markups by producing affordable, high-quality solutions.

Key Design Considerations

-

Stability and load capacity:

- Calculate the weight of the headset (e.g. 300-500 grams for premium models).

- If designing a heavier unit, widen the base or add counterweights.

-

Material selection:

- PLA/ABS/PETG: Ideal for plastic FDM printing—affordable and customizable colors.

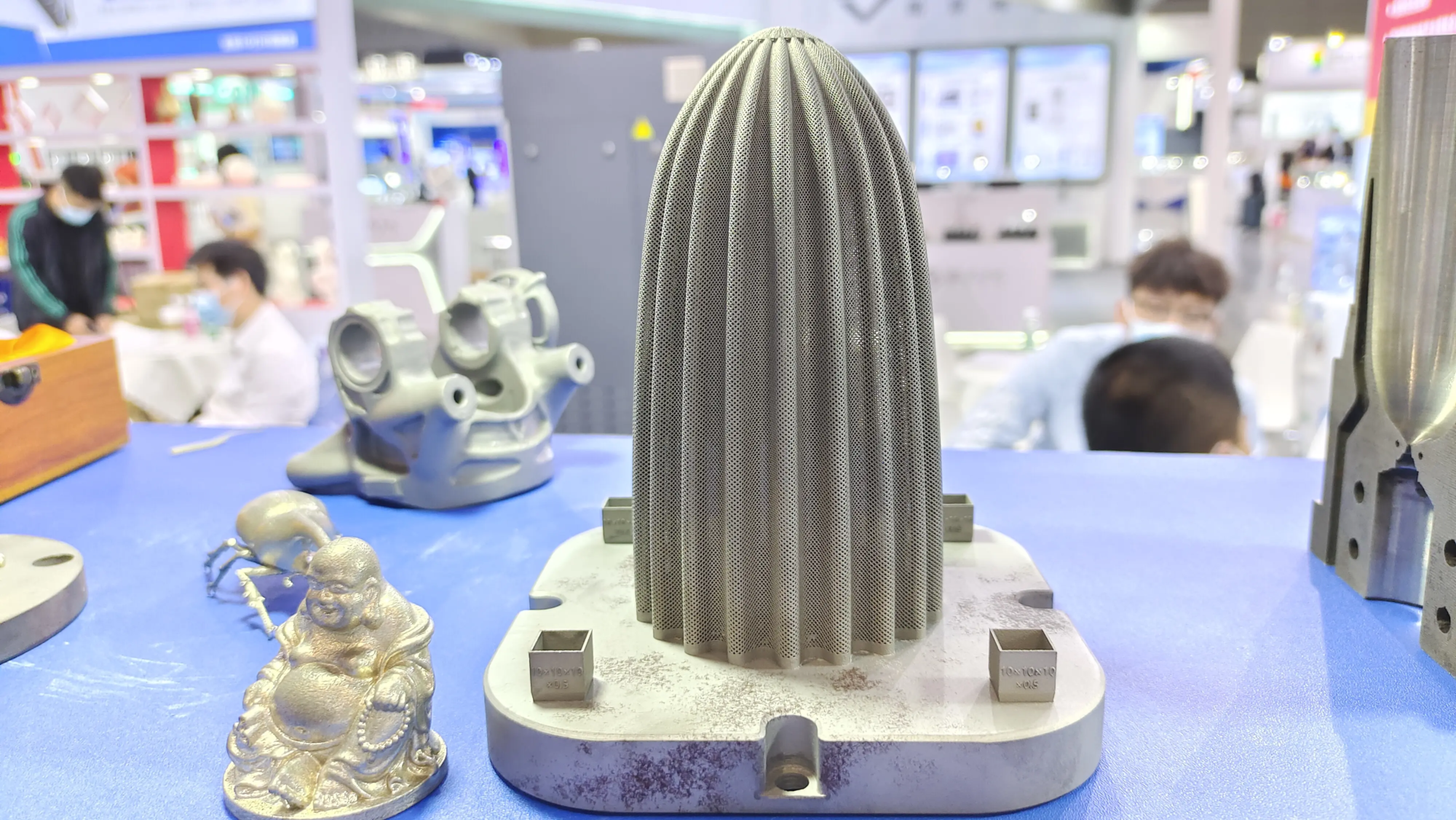

- Metal alloys (aluminum, stainless steel): Unparalleled durability with SLM/SLS printing. GreatLight’s specialized SLM (selective laser melting) systems produce corrosion-resistant, structurally strong metal stents.

- hybrid design: Combines metal joints with plastic parts for increased flexibility and strength.

-

Cable management:

Integrate clips, channels or hooks to organize cords – essential for a tidy desk. - Floor space and height:

Measure your desk constraints. Tip: Use the tallest headphones you have for modeling.

The power of professional 3D printing

Although DIY printers are suitable for plastic prototypes, Metal brackets require industrial-grade precision. This is where expert rapid prototyping shines. company likes huge light Good at:

- SLM 3D printer:Create strong, complex metal geometries not possible with traditional methods.

- End-to-end finishing: From sandblasted to anodized for matte, glossy or textured finishes.

- Material diversity: Custom titanium, aluminum, tool steel and custom alloys based on your requirements.

- speed: Functional prototypes are completed in days instead of weeks – perfect for iterative design.

GreatLight’s sophisticated technology ensures your stand can withstand daily use while looking premium – with no compromise between form and function.

Your design blueprint: step by step

-

sketching and conceptualizing:

Drafting ideas that balance art and physics. Consider cantilever designs, tree structures, or magnetic stands. -

3D modeling:

Use Fusion 360, TinkerCAD or Blender. Prioritize:- Pressure points (strengthens neck joints).

- Inclined support (to prevent slipping).

- Smooth contact surface (avoid scratches).

-

iterative prototype:

Print a plastic test version to verify fit. GreatLight’s rapid prototyping services allow for cost-effective adjustments before going to the metal. - final production:

If longevity and weight are important, choose SLM metal printing. Metal adds a luxurious, high-end feel and will last for decades.

Innovative add-ons to inspire

- Integrated charging: Embed in Qi wireless pad or USB hub.

- Modular: Stackable base to hold multiple headphones.

- Smart functions: If the earphones are not hung properly, the LED indicator or weight sensor will sound an alarm.

in conclusion

The Design 3D Headphone Stand transforms everyday storage into a display piece. It blends creativity and engineering to ensure your headphones fit securely while reflecting your personality. Whether printing plastic prototypes at home or working with industry leaders such as huge light To achieve metal excellence, the process democratizes innovation. Ready to create? Expertise in rapid prototyping "if what" Enter "here it is."

FAQ

Question 1: Can plastic 3D printing withstand heavy headphones?

Yes – clever design. Use PETG or ABS to increase flexibility and strength, and to widen contact points. For headphones over 500 grams, it is recommended to use metal reinforcement (especially at the connectors).

Q2: How can I ensure that my stand will not scratch my headphones?

Include a felt pad or silicone layer in the contact area. GreatLight post-processing can add non-abrasive coatings such as rubber paint.

Q3: Why choose metal instead of plastic?

Metal (Aluminum/Steel) offers superior longevity, stability and aesthetics. Ideal for studios or high-usage environments.

Q4: How long does it take to prototype using GreatLight?

Most functional prototypes ship within 5-7 days, including consultation and completion. Expedited service further speeds up the process.

Q5: Can I customize the surface treatment?

Absolutely. Options range from sandblasted matte to mirror polish, electroplating or custom textures – ask the GreatLight team for advice.

Q6: What is the cost difference between DIY and professional services?

DIY plastic prints start at less than $10. Professionally printed metal brackets range in price from $50 to $200 and reflect the premium quality of the material and enhanced durability.

Q7: Do you assist with CAD design?

Yes! GreatLight provides manufacturing-oriented design feedback to ensure your models are optimized for 3D printing success.

Ready to design your signature booth? Cooperate with Gretel Prototypes for bridging imagination and reality—precisely crafted and smartly priced.