As the world of 3D printing continues to evolve, the shortcomings associated with this innovative technology must be acknowledged. While 3D printing has revolutionized the way we design, prototype and manufacture products, there are not without limitations. In this article, we will dig into the shortcomings of 3D printing and explore the challenges faced by manufacturers, businesses and individuals when leveraging this technology.

One of the main disadvantages of 3D printing is the high cost of equipment and materials. Industrial-grade 3D printers can be very expensive, which makes it inaccessible to small businesses, startups and hobbyists. Furthermore, the cost of 3D printing materials such as metal powders and resins can be very expensive, increasing production costs. This limitation could make companies adopt 3D printing technology, especially for small-scale productions.

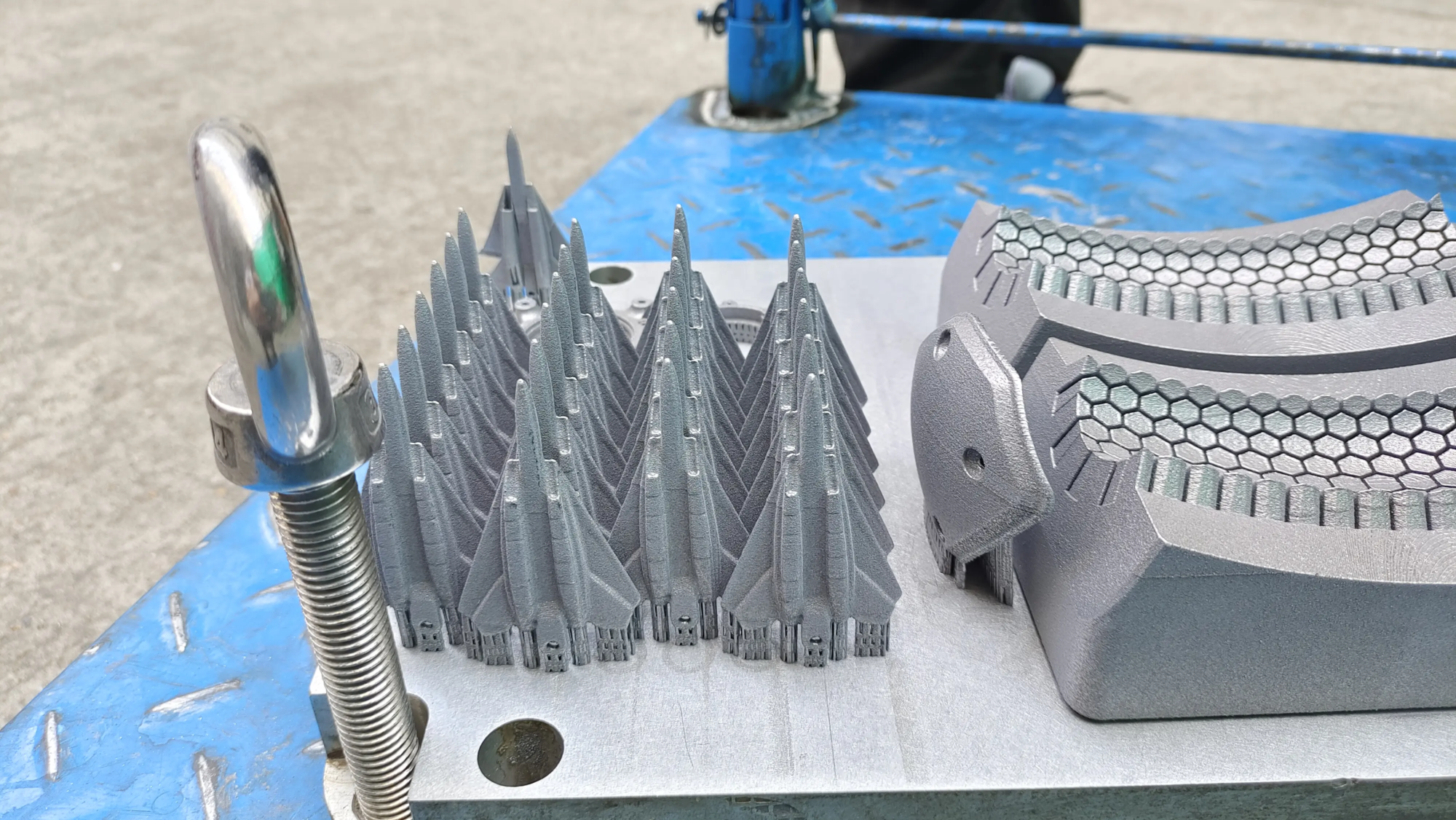

Another important drawback of 3D printing is the limited build size and complexity. Most 3D printers have limited build volumes, which can limit the size and complexity of parts that can be produced. Such restrictions are especially challenging for industries that require large, complex components such as aerospace and automotive. Furthermore, the layer-by-layer construction process may lead to limitations of geometric complexity, making it difficult to produce parts with complex internal structures.

The speed of 3D printing is another area of concern. Compared to traditional manufacturing methods, 3D printing can be a slow process, especially for large or complex parts. This can lead to extended production time, increased labor costs and reduced productivity. Additionally, the post-processing requirements for 3D printed parts can be time-consuming and labor-intensive, which increases the overall production time.

The lack of standardization in 3D printing is also an important disadvantage. The lack of standardized formats, materials and processes can make it challenging to ensure consistency and compatibility of different 3D printing systems. This can lead to problems with part quality, reliability and interchangeability, making it difficult to integrate 3D printed parts into existing production lines.

In addition, 3D printing has also raised concerns about intellectual property protection. The ease of copying digital designs and the ability to print copies of existing products can lead to patent infringement, copyright infringement and forgery. This can have a significant impact on companies that rely on intellectual property protection to maintain their competitive advantage.

In addition to these technologies and practical limitations, 3D printing also raises environmental and health problems. The production of 3D printed materials such as plastics and metals can have negative effects, including energy consumption, waste generation and pollution. In addition, inhaling particles and smoke during 3D printing can pose health risks to operators and users.

Finally, maintenance and repair of 3D printers can be a major challenge. The complex nature of 3D printing equipment requires specialized knowledge and expertise to maintain and repair, which can be time-consuming and expensive. In addition, the availability of spare parts is limited and the lack of standardized maintenance procedures can exacerbate these problems.

All in all, while 3D printing has revolutionized the manufacturing industry, it is essential to acknowledge the shortcomings associated with this technology. The high cost of equipment and materials, limited building size and complexity, slow speed, lack of standardization, intellectual property issues, environmental and health impacts, and maintenance challenges are all major limitations that must be addressed. By understanding these shortcomings, manufacturers, businesses and individuals can better address the challenges of 3D printing and unlock their full potential.

FAQ:

Q: What are the main disadvantages of 3D printing?

A: The main disadvantages of 3D printing include high costs of equipment and materials, limited build size and complexity, slow speed, lack of standardization, intellectual property issues, environmental and health impacts, and maintenance challenges.

Q: How to overcome the high cost of 3D printing equipment?

A: Consider outsourcing 3D printing services to professional manufacturers such as Greatlight, which provides affordable and high-quality 3D printing services.

Q: What is the environmental impact of 3D printing?

A: The production of 3D printed materials may have negative impacts on the environment, including energy consumption, waste generation and pollution.

Q: Can I use 3D printing for mass production?

A: While 3D printing can be used for mass production, it may not be the most efficient or cost-effective method, especially for complex or large parts.

Q: How to ensure the quality and reliability of 3D printed parts?

A: Work with reputable 3D printing manufacturers, such as Greatlight, which provides high-quality 3D printing services and strict quality control measures.

ISO 9001 Factory