Building the Perfect Headphone Stand: A DIY Journey into Functional Art

It’s a common sight on the modern desk: a pair of premium headphones, haphazardly placed near the keyboard or balanced precariously on the edge of the monitor. Not only does this look messy, but it also risks damaging your valuable audio equipment. A dedicated headphone stand elegantly solves this problem, blending organization with aesthetic appeal. While many people are tempted to buy an off-the-shelf solution, creating your own 3D printed headphone stand offers unparalleled customization, satisfaction, and often superior quality. This guide will walk you through designing and building a custom exhibition stand using the power of DIY 3D printing.

Why choose DIY and 3D printing?

Mass-produced stands often prioritize generic designs and low-cost materials, which can result in wobbly bases, weak hooks, or surface scratches on delicate headbands. 3D printing enables you to:

- Designed for your gear: Perfectly matched to your headband width, earcup size or weight distribution of your specific headphones.

- Optimized ergonomics: Place the hooks at the ideal height to prevent stretching or compression of the headband padding.

- Perfecting weight and stability: Design a base with a precise footprint and mass to feel rock solid and avoid annoying wobbles.

- Express your style: Incorporate unique patterns, logos, textures, and even functional elements like integrated cable management channels or matching holders for earbuds.

- Use ideal materials: Print with durable, non-damaging materials like PETG, ABS, or even rugged nylon to protect your gear.

Planning and Design: Combining Function and Form

-

Measure your headphones:

- Headband width: Measure the widest point on the inside of the band itself (where it meets the bracket).

- Hook height: Determine how high off the base the support hooks need to be to comfortably hang the headphones without them touching the table.

- Overall dimensions: Consider the space available on your desk.

-

Conceive your design:

- according to: Popular choices include solid rectangle/circle, minimalist "bean" Shapes, architectural forms or booths designed to resemble animals/game characters. Weight distribution is critical – a wider base or a design that allows for filler material such as concrete or metal pellets can increase stability.

- Stem/Column: Attach the base to the hook. Options range from straight lines to elegant curves or spirals (which can be printed with support structures).

- hook: Key functional components. Make sure the contact surface is curved, smooth and wide enough (usually 30-50mm is safe) to spread the pressure without causing deformation. Heated hooks (curved slightly inward) provide extra security. Rounded edges are a must!

- Design software selection:

- beginner: Tinkercad (web-based, intuitive drag-and-drop).

- middle: Fusion 360 (free for enthusiasts, powerful parametric modeling).

- Advanced: FreeCAD, Blender (complex curves, organic sculpting).

Key design tips for success:

- No sharp edges: All headgear contact points must be filleted/rounded (>2mm radius).

- Over-engineered basics: Make sure the base is much wider than the headset and has mass (either through solid filling or the ability to add ballast).

- Avoid thin features: The wall should be designed to be at least 2-3 mm thick, and the hooks should be thick enough (6-8 mm) to avoid cracking.

- Consider printing orientation: Imagine how the model will lie on the print bed. Avoid using support structures on critical smooth surfaces, such as headband hook contact areas. Splitting the model (e.g. separate base, stem, hook) improves printability and post-processing.

DIY Building Process: Step by Step

- Finalize your model: Use measurements and software to create your unique STL file. If possible, test components virtually.

- Slice the model: Prepare for printing using slicing software (PrusaSlicer, Cura).

- Material selection: Prioritize durability and surface finish:

- People’s Liberation Army: Easy to print in a variety of colors; will warp under constant pressure/heat. Best for filling bases.

- Polyethylene glycol: Excellent durability, impact resistance and good inter-layer adhesion. Highly recommended for hooks and rods.

- ABS/ASA: More challenging, but great for finish and heat resistance; requires a case. Good ventilation is required.

- TPU (flexible): Protective cover for hook surface.

- Print settings:

- Perimeter/Walls: 3-4 walls for strength.

- Filling density: Structural parts (stem, hook): 40-60%. Heavy base: 70-100% or designed to incorporate ballast.

- Floor height: 0.2mm allows for a good detail/strength balance. 0.15mm, the visible surface is smoother.

- slow down: Printing critical strength parts, such as hook connections, a little slower can reduce risk.

- brim/raft: For tall, slender stems or a thick base it is critical for bed adhesion.

- print: Make sure your bed is level and the filament is dry. Monitor the first level closely.

- Post-processing:

- Support removal: Use pliers/blade scissors to carefully remove the supports. Scrape or sand rough areas.

- Polishing: Sand gradually from coarse to fine to obtain a smooth contact surface.

- assembly: If multi-part, use strong adhesive (2 part epoxy, CA glue). Test thoroughly for fit.

- Ballast (optional): Fill the hollow base cavity with modeling clay, sand, or metal pellets before sealing (design a manhole!).

- Finishing touches:

- painting: Apply a primer (specifically for 3D printing), sand lightly, then use spray paint or acrylics.

- Install the felt/pad (vital!): Apply strips of adhesive-backed felt (EVA foam will also work) where the headband will be to prevent scratches and increase grip.

- Clear Coat: Protects paint/graphics and prints from UV rays (especially PETG).

Beyond DIY: When Precision Matters

DIY 3D printing can be worthwhile, but sometimes technical limitations (printer size, material limitations, need for ultra-polished finishes or specialty metals like aluminum/stainless steel) require expertise. where is this Gretel Advanced Prototyping Technology Excellent performance.

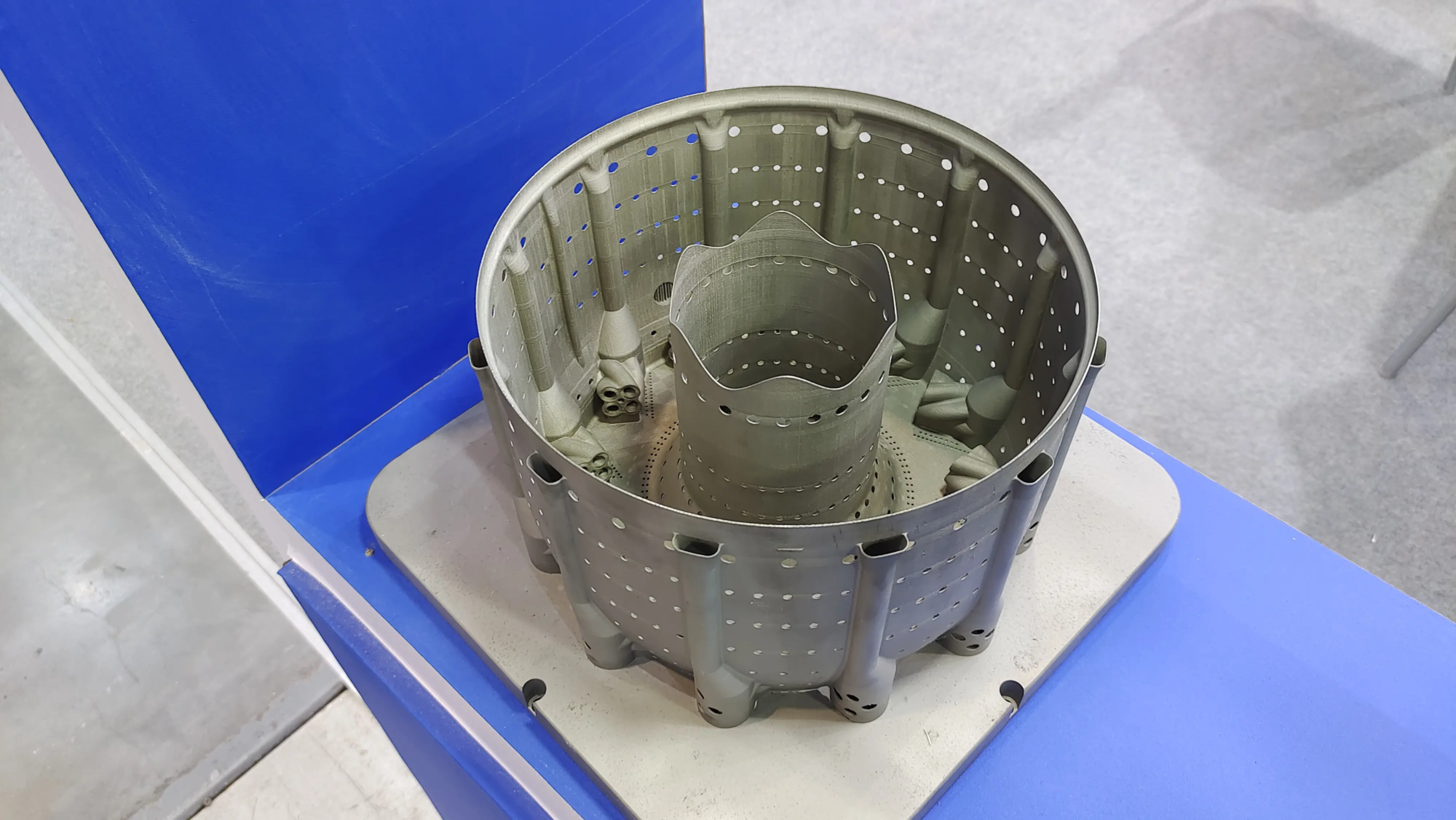

We utilize state-of-the-art technology SLM (Selective Laser Melting) 3D Printer and complete production technology to meet the challenges of complex metal rapid prototyping. Does your headphone stand have a complex design that requires flawless execution, the durability of aircraft-grade aluminum or a mirror-polished stainless steel finish? Gretel offers a comprehensive One-stop post-processing service – CNC machining for critical dimensions, sand blasting, polishing, powder coating, anodizing – ensuring your parts meet precise functional and aesthetic standards.

We focus on Quick customization with wide selection of materialsprocessing most orders with extremely short turnaround times. Whether you’re perfecting an initial DIY prototype or looking for a high-volume production-ready solution, GreatLight provides professional-grade solutions Precise rapid prototyping at competitive prices. Discover the difference expertise makes when form and function need to coexist perfectly.

Conclusion: Elevate your desk and protect your equipment

Building your own 3D printed headphone stand is more than just a practical project; it’s an opportunity to create functional desktop art that’s perfect for you and your device. It eliminates the clutter problem while providing superior protection compared to throwing your headphones on the table. Design flexibility, creative satisfaction, and potential cost savings make DIY 3D printing an excellent approach. For those looking for unparalleled sturdiness, precision or finishing brilliance, especially in durable metals, partner with a professional service such as huge light Unlock new levels of performance and aesthetics. Make your perfect stand today and place your headphones in the custom holder they deserve.

FAQ: DIY 3D Headphone Stand

Q1: Will the 3D printed stand damage my headphones?

one: A well designed and finished product will not. The key is:

- Round hook: Generous curves prevent pressure points.

- Smooth surface: Sand the printed lines or supports away from the contact surfaces.

- critical: Apply Soft adhesive-backed felt or foam pad Where the headband is located. When it comes to protecting quality finishes, there’s no compromise. Avoid direct contact of exposed 3D printed plastic with the painted/metal headband.

Q2: What is the best material for a sturdy 3D printed headphone stand?

one: polyethylene terephthalate Typically the best consumer-grade filament blend: durable, impact-resistant, has good inter-layer bonding, and won’t warp over time under pressure like PLA. ABS/ASA Not bad, but more difficult to print. For ultimate professional quality and durability, metal printing (Aluminum or stainless steel via SLM/DMLS) through services like huge light Provides unparalleled strength and longevity.

Q3: How heavy should the base be?

one: Balance the leverage of your headphones. Heavy headphones (400g+) require a sturdy base. Aim for a base that feels like solidly Heavier than headphones. Design features:

- A lot of: Physically larger (e.g. 150x100mm minimum) and use high infill (>70%) or incorporate ballast space (sand/metal pellets).

- footprint: A wider base is more effective at improving stability than just adding mass.

Q4: Can I print the headphone stand without the Slicer stand?

one: It depends on your design. Simple block designs with slight overhangs can often be printed support-free with a good bridge setup. However, curved hooks, complex stem shapes, or significant overhangs will Need support. Strategically segmenting the model and reassembling it after printing can often minimize the need for supports on critical surfaces.

Q5: My hook feels rough after printing. How can I make it smooth and safe?

one:

- Carefully remove supports: Use a flush cutter and needle.

- Polishing: Sandpaper grit (for example, 120 -> 220 -> 320 -> 400 grit). Wet sanding can help.

- Filler/Primer: Apply filler primer and sand again.

- Felt/Foam: Crucially, the last touchpoint is covered Filler should be used whether sanding is successful or not. Sanding alone usually won’t make filament plastic as smooth as molded plastic over the long term.

Q6: I don’t have a 3D printer. Can I still get a custom mount?

Answer: Of course! company likes huge light Focus on making your custom design a reality. Simply provide your 3D model files and they will handle the rest – material selection (including premium metals), precision printing (SLM for metals, SLS/FDM for plastics) and professional post-processing finishing. This is ideal for those who need an ultra-polished, ultra-durable or metal stand without investing in expensive printers and materials. GreatLight’s services provide fast turnaround and expert quality control even for complex or one-off designs.