Embrace innovation in backyard agriculture: DIY 3D printed chicken feeder

Raising backyard chickens bring joy, fresh eggs and connection to nature. But, honestly – daily chores, such as filling scattered feeders, can feel bored. What if technology could simplify this? Enter 3D printingchanged the game rules of DIY poultry solutions. Forget the feeder purchased by the GM store; imagine a custom designed, perfectly sized and easy to maintain feeder for your chicken coop. This blog delves into how to create 3D printed chicken feeders that leverage modern prototypes to address ancient agricultural nuisances.

Why 3D printed chicken feeder?

Traditional feeders often have limitations: they waste feed, attract pests or tend to tilt easily. 3D printing offers compelling advantages:

- custom made: Adjust the size of the sheep size or chicken house layout.

- Reduce waste: Design precise mechanisms (such as pedals or gravity doors) to minimize spills.

- Durability: Use UV-resistant, non-toxic materials that can withstand weather and peck food.

- Sustainability: Repair or iterate parts instead of replacing the entire unit.

Design feeder: Key considerations

- First of all, safe: Explore the chicken with a beak, so please use Food safety materials (e.g. PETG or PLA) prevents chemical leaching. Sand the surface to avoid injury.

- Function:choose:

- Gravity feeding hopper: Very suitable for consistent feed flow.

- Pedal mechanism: Weight activated lids prevent rodents and wild birds.

- Modular: Design replaceable components (e.g., feeding trays) for easy cleaning.

- environment: Explain rain, sunshine and humidity. Add drain holes and overhangs to keep feed dry.

Building it: Step by step overview

- Source Design: Find open source templates on platforms like Thingiverse, or create your own open source templates using CAD tools like Tinkercad.

- Material selection:

- PLA: Affordable and easy to print (preferably non-stained variant).

- Petg: Waterproof, more sturdy outdoor use.

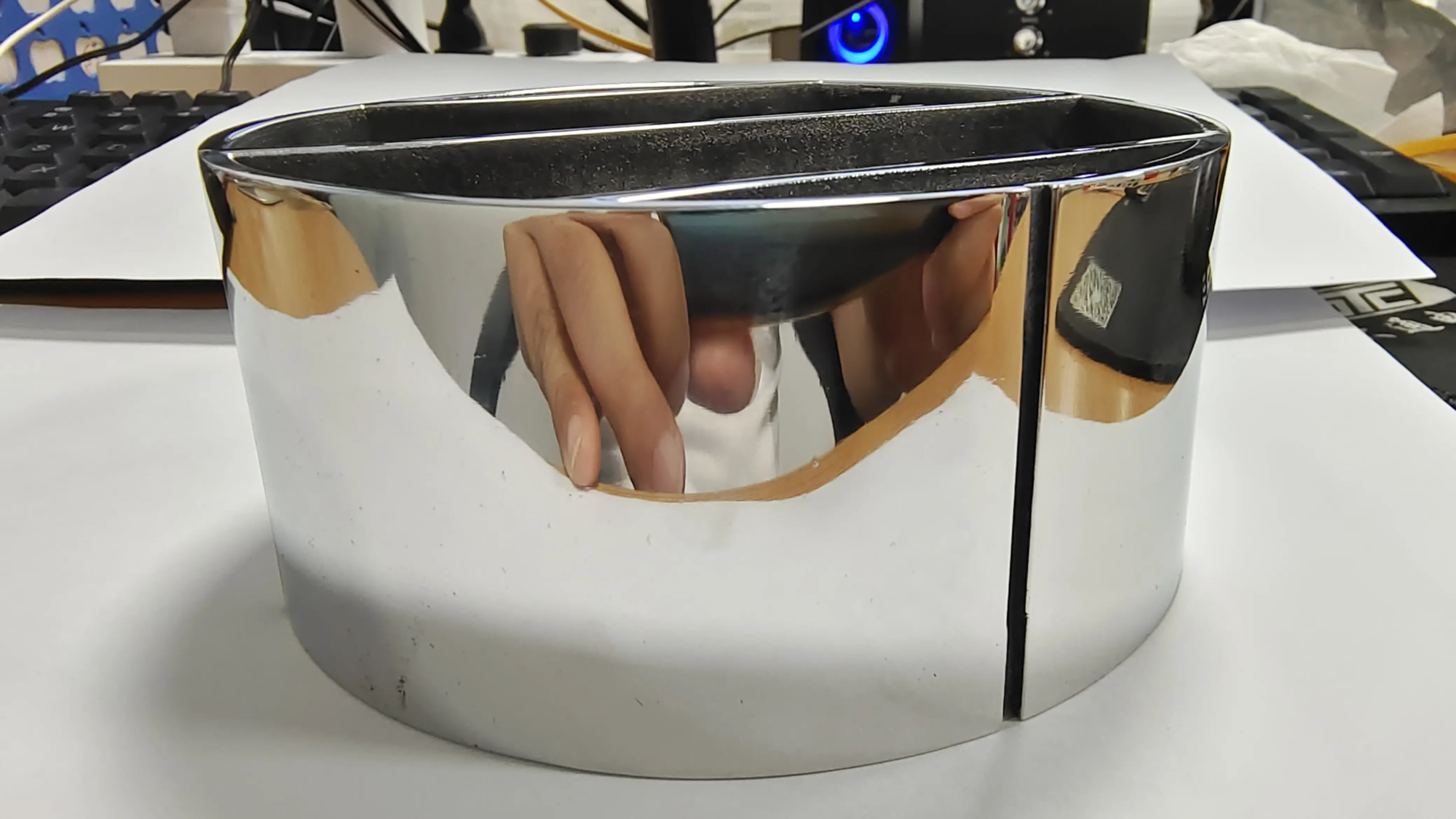

- Professional Metals: For critical parts (e.g., hinges) that require extreme durability, consider Stainless steel Printed by SLM (Selective Laser Melting).

- print: Use a nozzle of ≥0.4mm to perform solid walls. Apply food grade epoxy and print seal for humidity resistance.

- assembly: Use stainless steel screws or bird-safe adhesive to capture printed parts together.

When DIY encounters professional precision

Designing at home is fun, but complex components require industrial-grade reliability. This is Great® Specializes in. As a leader Rapid prototypingWe support backyard farmers in dealing with ambitious projects:

- Advanced SLM 3D printer: Corrosion-resistant with low light accuracy, carrying metal parts (such as pedal springs).

- End-to-end post-processing: Smooth, polish, sterilize or food coating for safety and longevity.

- Quick customization: Redesign the twisted stand? Do you need 20 units? Our teams are fast mass-produced production through materials from titanium to biocompatible alloys.

Whether your plastic prototype needs refinement or requires a heavy-duty stainless steel feeder, Gregmight combines agricultural creativity with aviation-grade manufacturing to provide you with time, money and feed.

in conclusion

A 3D printed chicken feeder blends tradition with innovation, giving you the ability to build smarter, cleaner chicken coop solutions. When enthusiast printers process basic versions, professional services such as Greatlight® have elevated the design to endure the toughest pecking and storms. Embrace this technology-driven approach and enjoy more time watching your chickens instead of replenishing feed.

FAQ

Q1: Can 3D printed plastic be safe for chicken feed?

A: Yes, if you use Food grade, BPA silk-free Like PETG or PLA. Post-treatment with non-toxic sealant can prevent microorganisms. The sand edges are smooth to prevent injuries.

Q2: Can I use a home printer to print the entire feeder?

Answer: The basic design (up to 6-8 chickens) works very well. For complex shaping, divide the model into sections. Large-scale or all-metal feeders are better outsourced to industrial solutions.

Q3: How to use 3D printing design to reduce feed waste?

A: Integrated pedal system (chicken pedals on the plate to open the lid) or adjustable feeding port. Add a basin pallet to pour the pellets down.

Question 4: Will rain destroy my feeder?

A: Design roof/overhang or choose weather-resistant materials such as ASA or sealing metal. Avoid porous printing containing moisture.

Q5: Why use professional rapid prototyping services (such as Greatlime)?

A: For precise overhead parts, metal hinges, rat-proof latches or 50 unit batches can be considered. Industrial printers ensure structural integrity and faster production compared to home machines. It is perfect for solving tricky chicken feeding puzzles or expanding production.

Q6: How long does the 3D printed feeder last?

A: The PLA model for home printing may last 1-2 years of outdoor activities. PET lasts longer. Professionally printed stainless steel can be used continuously for minimal maintenance within ten years.

Today, you can use Tech’s collaboration without an engineering degree!