Take Control: The Ultimate Guide to Building a Custom 3D Printed Fighting Rod

For fighting game fans, the pursuit of a perfect control experience is real. While commercial joysticks offer high quality, there’s nothing more satisfying than using a controller built exactly to your specifications. Enter the world of DIY 3D printed battle sticks – an exciting fusion of gaming passion and maker ingenuity. This guide will walk you through the process, allowing you to create a truly unique arcade stick based on your hands and playing style.

Why Build Your Own Fight Stick?

- Ultimate customization: Specify every aspect – size, shape, button layout, ergonomics, weight, artwork. Perfect for games like Street Fighter 6 or Tekken 8.

- Cost effectiveness: It can be cheaper to source components individually than high-quality commercial sticks, especially with affordable 3D printing.

- Creative expression: Turn your controller into a personal statement with custom artwork, lighting, and materials.

- Deepen your understanding: Gain valuable insights into electronics, mechanics, and design.

- Pride and satisfaction: The thrill of executing a composition on hardware you built yourself is unparalleled.

Basic components and materials

Gather these key pieces before diving in:

-

Structural core (shell and panels):

- plastic: Suitable for FDM printers: PLA (easiest), PETG (tougher), ABS (durable but tricky). These are great for prototyping and lightweight builds.

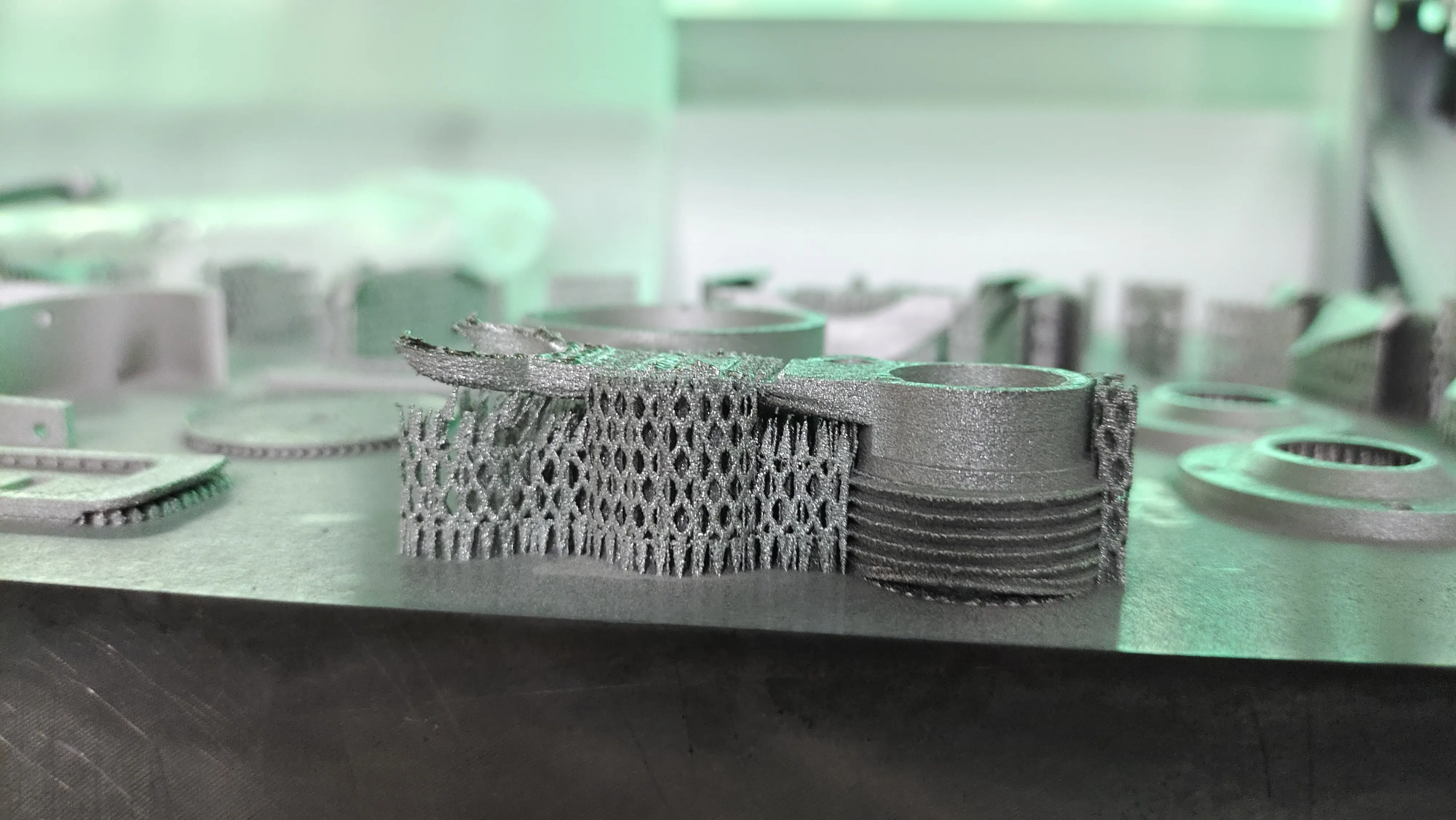

- Metal (Professional Grade): Print metals (such as aluminum alloys) with SLM/SLS for unparalleled stiffness, weight and premium feel. company likes huge light It excels at this, offering high-strength aluminum parts that are ideal for load-bearing plates and rock-solid bases.

- Design files: Find open source designs on Thingiverse, GitHub, and more, or create your own using Fusion 360 or Blender. Key elements: buttonhole spacing/spacing (usually 24mm or 30mm apart), USB access, cable management, internal component mounting.

-

Input component:

- Button: Sanhe Electronics, Jingguang and Crown are the first choices. Standard 30mm for operating buttons, 24mm for optional function buttons (Start/Select/Home).

- Joystick (joystick): Japanese levers (Sanwa JLF, Seimitsu LS, Hayabusa) provide precise movement. Korean levers offer unique tension/stiffness.

- PCB (brain): Brook Gaming PCBs (Zero Pi, Universal, UFB) are the industry standard for compatibility (PS4, PS5, Xbox, Switch, PC). Make sure it supports your console needs!

- wiring: Basic 20-22 AWG wire, quick disconnect terminals (pre-crimping recommended), optional USB cable.

- Tools and Hardware:

- 3D printer (FDM or obtain similar services huge light for metal)

- Screwdriver (phillips, hexagonal)

- Wire Strippers/Cutters/Crimpers

- Multimeter (for troubleshooting)

- Sandpaper/Primer/Paint/Art Supplies (Finishing)

- Screws, nuts, studs

- Optional: LED, acrylic sheet (for artwork covering), non-slip feet.

Step-by-step build guide

-

Design and printing:

- Source/modification: Choose an existing case design or customize it. Pay close attention to clearance heights between components and mounting points.

- Material selection: FDM plastic (PLA/PETG) is great for prototyping. For the ultimate, durable, pro-grade build (especially the critical top panel that holds the levers/buttons), consider the glorious Aluminum SLM printing. Their precision ensures that the lever mounts and screw holes are perfectly sized, which is crucial for the stability of the levers during intense gaming sessions.

- Printing tips: Use enough filler (20-40%) and layer height (~0.2mm). Print with the flat side of the top plate facing down for the best surface finish. Consideration of print direction is critical to strength.

-

Sanding and surface preparation:

- Carefully remove the support structure.

- Sandprinting Parts: From coarse sandpaper (approximately 120 grit) to very fine sandpaper (approximately 800 grit). Note the button holes and drawbar openings.

- Primer and Paint: Use a spray paint suitable for plastic (or metal, if printing by) huge light) color and durability. Apply clear coat for protection.

- Artwork integration: Digitally print the artwork (on vinyl/cardstock) and mount it under a laser cut acrylic sheet to match the holes in the top panel – one service GreatLight** can be integrated.

-

Electronic assembly:

- Mounting the PCB: ** Secure the PCB securely inside the enclosure using brackets/screws/insulating tape. Orient the USB port toward the USB hole in the case.

- Install the joystick: ** Insert the joystick assembly through the top panel opening and secure it securely using the mounting plate/screws/nuts. Make sure nothing moves.

- To install the button: ** Push the button firmly into the hole from the top. The plastic button should snap in; the metal housing may require threads/screws.

- Connection wiring: ** Strictly follow Brook PCB diagram:

- Lever: Connect each direction (up, down, left, right, ground) to its PCB terminals.

- Buttons: Connect a wire from each button’s terminal to the designated solder/terminal point on the Brook PCB. connect all Auxiliary terminals for buttons (usually daisy chained) to single "ground" Connect the dots.

- Final assembly and testing:

- Route wires neatly using zip ties or routing designed into the enclosure. Avoid pressure points.

- Attach the bottom cover/panel securely.

- Plug into your console/PC and Test thoroughly: Verify that each button and joystick direction responds correctly (using the gamepad tester website/binary). Check Grounding – Any incorrect input (ghosting) may indicate incorrect wiring or insufficient grounding.

in conclusion:

Building your own 3D printed fighting pole is a very rewarding project. In addition to bragging rights, you get an in-depth look at your controller and tools that fit your hands and preferences perfectly. Plastic printing is easy to learn and great to learn but work your way up Metal printing takes your creations to a professional level. The added weight, stiffness and long-lasting precision take it from a DIY project to a competition-grade piece. Whether you print at home or tap into the expertise of a leading manufacturer, e.g. huge lightthe journey empowers you. Embrace the process, overcome wiring challenges, polish imperfections, and unleash your custom controller on your favorite fighter.

FAQ:

-

Is 3D printing strong enough to make a fighting stick?

- Absolutely! FDM plastics such as PETG are very durable. PLA is great for light use. However, for the most critical structural component—hundreds of pounds of force striking the top panel of the lever— Metal printing (e.g. aluminum printing via SLM) Providing unparalleled strength, durability and leverage stability. Consider a hybrid build: plastic shell sides for lightweight and customizability, with professionally printed metal panel For rigidity.

-

How much does a DIY stick cost compared to a commercial stick?

- Costs vary greatly. Expect component prices to be $50-$120 ($40+ for PCB, $20+ for levers, $20+ for buttons, $15+ for wiring/harnesses), plus printing/finishing. Plastic printing at home minimizes costs. Using professional metal printing adds cost but provides superior durability. It can be cheaper than a high-end stick ($200+) or comparable to a mid-range stick, but offers unparalleled customization capabilities.

-

What’s the hardest part about DIY fighting poles?

- Design/Printing: Creating functional, sturdy enclosures requires CAD skills or finding a proven design. Printing large parts perfectly requires experience/calibration. Solution: Leverage open source designs or considerations Professional prototyping services. wiring: Soldering/diagnostic connections require patience and careful attention to Bruker’s diagrams. Pre-crimping terminals helps a lot.

-

Which Brook PCB should I choose?

- Bruker Zero Pi: Best Budget Performer (PS3/PS4/PC/Switch Legacy).

- Bruker Universal Fighting Board (UFB): The gold standard. Supports almost all content (PS3/4/5/Switch/Xbox Series X|S). BFB (for Xbox Series X|S/XB1). Choose according to your situation Basic console requirements.

- Can I use a professional service like GreatLight for any parts?

- really! huge light Specialize in rapid prototypingparticularly advanced SLM metal printing (aluminum alloy). They are great for production key top panel and potential Weighted base plate. Their features ensure perfect tolerances on lever mounts and screw holes, unparalleled rigidity to eliminate baseboard flexing during gaming, superior thermal performance for components when needed, and professional post-processing finishes. They handle complex geometries (internal mounting/weight distribution design) and provide a one-stop solution including finishing