Greening Your Space: The Ultimate DIY Guide to 3D Printed Flower Pots (Plus Pro Tips!)

There’s something deeply satisfying about growing plants, and combining that with the creative freedom of 3D printing takes that satisfaction to a whole new level. Forget your average store-bought planter; imagine designing a container that perfectly fits your succulent roots, minimalist decor, and even an integrated smart watering system. Welcome to the world of DIY 3D printed flower pots!

Why 3D print flower pots?

In addition to being fun, 3D printed flowerpots offer unique advantages:

- Super customized: Design pots around a specific plant’s root depth, aesthetic theme (geometric, organic, whimsical) or tricky shelf space.

- Sustainability: Use biodegradable PLA filament, recycle failed prints and avoid mass production of plastic.

- Problem solving: Do you need drainage holes? Multiple layers? Built-in saucer? You design it.

- Auxiliary functions: Affordable desktop FDM (fused deposition modeling) printers make it easy for hobbyists to do just that.

Getting Started: Your Tools and Materials

1. Printer:

- FDM printer: Very suitable for beginners. Models like the Creality Ender 3 or the Prusa i3 are popular. They are cost-effective and print well using materials suitable for plant pots.

- Resin printer (SLA/DLP): Produces extremely smooth, detailed pots. Requires more post-processing (cleaning, curing), and uses a resin that may not be plant-safe long-term without sealing. For practicality, stick with FDM.

2. Filament – choose wisely:

- PLA (polylactic acid): Flower pot star! Derived from corn starch/sugar cane, biodegradable (industrial), odorless, and easy to print. Choose PLA+. Avoid direct sunlight/high temperature for long periods of time.

- Polyethylene glycol: More durable and heat/UV resistant than PLA. Ideal for outdoor pots exposed to mild sunlight. Drawn easily; needs adjustment.

- Avoid using ABS: The casing needs to be heated, smoke is emitted during the printing process, and it’s not very environmentally friendly.

- Metal or stone filled PLA: Available in unique finishes (bronze, granite-like) but may require careful handling and sealing.

3. Design software:

- beginner: TinkerCAD (simple browser-based modeling).

- middle: Fusion 360 (powerful CAD with free hobbyist license) or Blender (organic shapes).

- Source code ready: Platforms like Thingiverse, Printables, and Cults3D have thousands of free potting designs. Filter by "planter" or "pot."

Designing your perfect planter: key considerations

- Drainage is non-negotiable: Always include drainage holes (minimum diameter 3-5 mm). Raise the bottom slightly or add Raspberry Pi patterned holes for aesthetics. Designed with built-in integrated saucer to fit larger pots.

- Thickness issue: Walls thinner than 1.5mm are at risk of rupture; thicknesses greater than 4mm are scrapped/time. Aim for 2-3 mm as an ideal target.

- Nemuro: Study your plants! Add a 2-5cm gap around the expected size of the root ball. Depth is critical for carrots, snake plants, etc.

- Texture and ventilation: Add grooves, ridges or subtle air gaps to aid soil drying and root health.

Printing protocol: successful setup

- Bed adhesion: enable edge (especially for narrow pots) or raft (If the base has intricate details).

- filling: 15-25% is enough – keep the pot lightweight. Use gyro or grid patterns to increase force efficiency.

- Number of layers: A layer height of 0.2 mm provides a good speed/surface quality balance.

- Wall/Perimeter: Use 3 more perimeters (walls) to increase strength and waterproofing.

- support: Required for true overhang >60 degrees. Avoid placing supports in the cavity unless absolutely necessary – they are difficult to remove. Use tree supports sparingly.

Post-processing: Make it beautiful and protected

- seal: Although PLA is waterproof, moisture penetration will affect its service life. seal:

- Clear acrylic spray paint/sealer (multiple coats).

- Food safe epoxy (ideal for interior coatings, adds water resistance and shine. Make sure to cure completely!).

- finishing: Sand ranges from coarse (~120 grit) to fine (~400+ grit). Wet grinding PLA works well.

- decorate: Use non-toxic acrylic paint after sealing. Add glitter/glow pigments to resin!

Go beyond the basic pot – unleash creativity

- Automatic watering system: Design pots with reservoirs accessible from below (use strips of capillary action felt).

- Sensor fusion: Embed humidity/light sensors in the space that connect to vintage displays or IoT systems.

- Wall magic: Design a stunning geometric wall-mounted planter or terrarium. Optimize print orientation for increased strength.

- triple: Modular stacking system for printed herbs – grow peas, basil and parsley vertically.

When DIY reaches its limit: The advantages of professional prototyping

What if your dream planter needs an impossible angle…or can withstand the Arizona sun? What if it wasn’t plastic, but had an intricate pattern? Metal? This is where professionalism comes in rapid prototyping Improve your horizons. Enter huge light.

as a leading Chinese rapid prototyping manufacturer, huge light Leveraging technology that’s light years ahead of desktop printing:

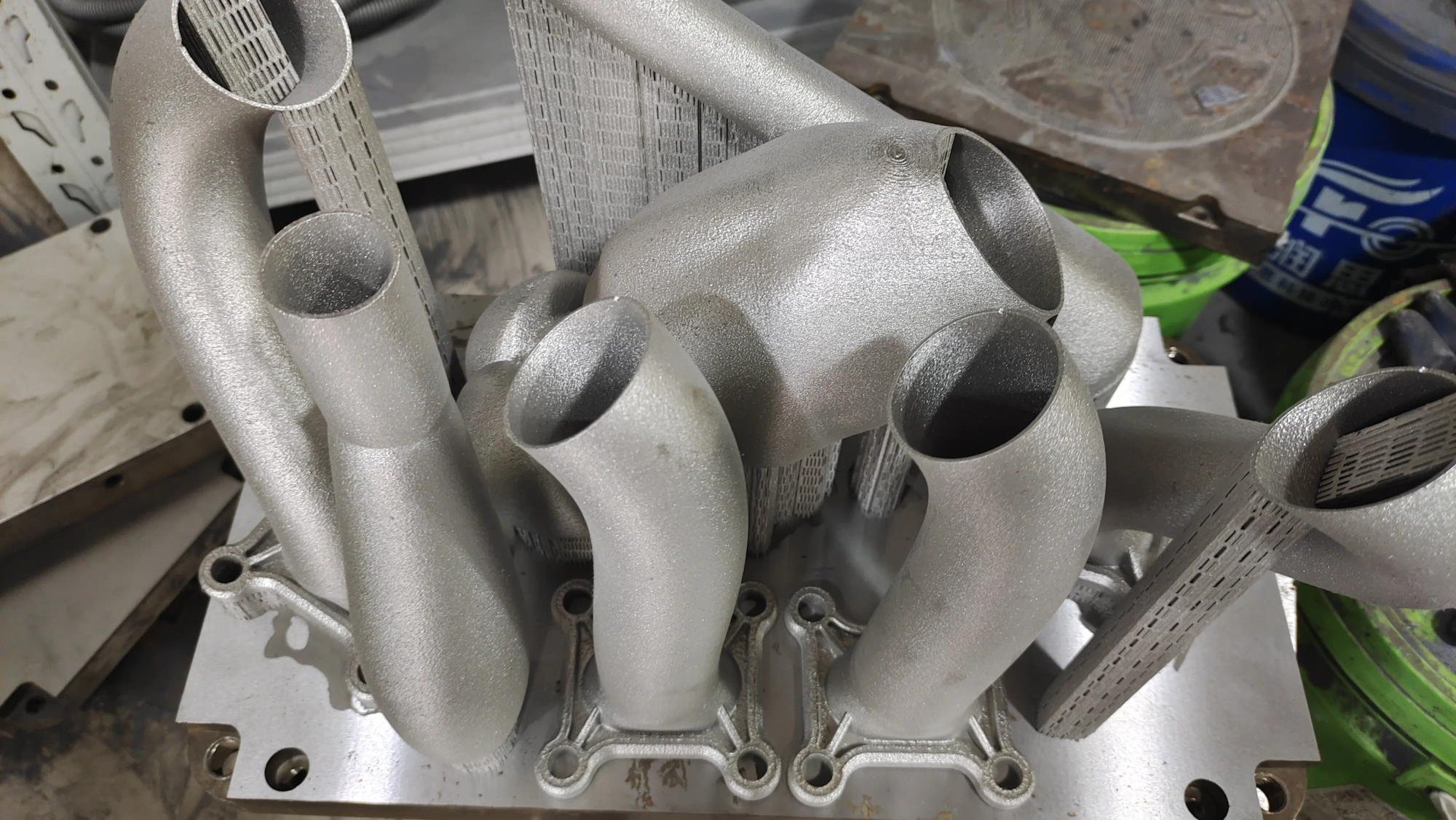

- Industrial grade metal: use Selective Laser Melting (SLM)GreatLight creates sturdy, sophisticated metal basins ideal for demanding outdoor/public installations or bespoke luxury designs. Think of a brass, titanium or stainless steel flower pot whose lattice structure cannot be cast or machined.

- End-to-end service: GreatLight can handle it all:

- Expert file optimization for manufacturability.

- SLM printing For complex metal geometries.

- Professional post-processing: Precision machining (CNC), sandblasting, polishing, electroplating, anodizing – for a museum-quality finish.

- Speed and customization: Need a prototype of a laminated ceramic/glass-filled nylon composite basin in days? Gretel specializes in Quick turnaround Without compromising accuracy while adapting to virtually any material specification.

- Why choose Pro version? When your vision requires extreme durability, unique composites, flawless mass-production parts, or corrosion/weather-resistant metals, professional prototyping will unlock possibilities not possible with consumer-grade printers.

Turn your precise rapid prototyping vision into reality. Giant Light United Advanced SLM equipmentdeep materials science expertise and strict quality control deliver custom metal and composite parts that perform beautifully. Get best-in-class rapid prototyping solutions tailored to your needs – Request a competitive quote today!

(Find GreatLight online: your high-risk prototyping and production solution.)

in conclusion

3D printing your own planter combines botany with limitless creativity. Start simple: nail drainage, understanding filaments, mastering microtome settings. From quirky desk companions to sensor-filled smart ecosystems, DIY printing allows you to reach beyond the pot aisle. When ambitions extend to metal art or ultra-durable composites, partners like huge light Bridging the gap between imagination and industrial-grade reality. So fire up your printer, design your planters, embrace the filament tango, and watch your greens—and be clear personal –Thumb boom!

FAQ: Answers to DIY 3D Printed Flower Pots

Q1: Is it safe to grow edible plants/basil in PLA?

one: Uncoated PLA itself is generally considered non-toxic. However, its porous nature traps moisture and bacteria over time. Always seal the interior with food-safe epoxy For safe consumption. Avoid using resin over exterior pre-cure.

Q2: Why does my flowerpot crack/leak after a few months?

one: Common culprits:

- Thin walls (<1.5mm) crack under stress.

- Unsealed PLA will gradually degrade due to UV/sun exposure or continued moisture leakage.

- Use standard PLA (fading and weakening) outdoors in harsh sunlight – use PETG or specialized UV resistant/composites. Always seal the inside!

Q3: How can I make my flowerpot truly waterproof?

*A: Internal sealing is key:**

- Clean/dry the interior thoroughly.

- Apply Food safe epoxy resin – Apply evenly as directed (twisting is usually required).

- Allow time for full cure (usually 72+ hours). A light color spray/paint on the exterior helps minimally.

Q4: Can I print potted plants directly outdoors/under sunlight?

one: Standard PLA will deform and degrade. If outdoors:

- use polyethylene terephthalate filament or Polylactic acid+.

- Look for a primer/paint that is UV resistant.

- Best for outdoor activities: Professionally printed parts pass huge light Metal or advanced polymer for weather-resistant design.

Q5: What is going on? "food safety" print? Worried?

one: Tabletop printed planters pose two microbial-related risks:

- Tiny layer gaps harbor bacteria/mold.

- The filament absorbs impurities during the printing/sealing process. seal This situation is significantly mitigated. Risk is minimized by using FDA compliant filament/epoxy. For critical applications, use professionally finished solid metal (via SLM) parts from trusted sources, e.g. huge light.

Question 6: I need hundreds of identical pots – can I print them commercially?

one: Desktop FDM Yes Very Mass production is slow. Valid expansion requires:

- Industrial printers (large format/high throughput).

- Injection molding (Once processed, the yield is cheaper/higher). explore rapid prototyping bridge statue huge light – Prototype with rapid 3D printing, then scale seamlessly with optimized manufacturing pathways.

Ready to innovate? Whether tinkering at home or expanding your vision with a professional prototyping partner, the future of personalized gardening starts at the print bed!