Embrace green innovation: Making your own 3D printed meat pot

Succulents attract gardeners and minimal maintenance in their sculptural form. But why adapt to a universal flower pot when you can blend gardening with cutting-edge technology? 3D printing unlocks unrivaled creativity when designing custom artifacts that suit your space, style and juicy needs. This guide explores DIY 3D printed pots, from design to post-processing – and how professional services like Great Improve the project requires industrial-grade quality.

Why 3D printing a juicy pot?

- Customization Free: Design pots in any shape – geometric, animal inspired or interlocked set. Adjust drainage holes, soil depth and reservoir for plant health.

- Sustainability: Use biodegradable filaments such as PLA (derived from corn starch) or new spools in failed prints.

- Cost Efficiency: Print small pots, materials compared to the materials of store-bought alternatives.

- Educational Value: Ideal for learning 3D modeling, printing setup and botany.

DIY process: step by step

-

Design pot:

- software: Beginners use Tinkercad or Thingiverse templates; advanced creators utilize Fusion 360.

- Key Features:

- Includes 3-5 drainage holes (diameter 1-2mm) to prevent root rot.

- Add a removable disc or internal water flow layer.

- Elevate the base of the airflow (for example, small feet).

-

Material selection:

- PLA: Affordable, non-toxic, with bright colors. Avoid prolonged exposure to sunlight to prevent warping.

- PETG: Weather resistance to outdoor use.

- Regenerated filaments: Environmentally friendly options such as recycled pets reduce environmental impact.

-

Printing best practices:

- Layer height: smooth surface 0.2mm.

- Filling: Lightweight and durable 15–20%.

- Support: Use tree support for complex overhangs (e.g., lattice design).

- Post-processing:

- The sand has rough edges with 200-grain sandpaper.

- Sealed with food-safe epoxy resin to block tiny pores where bacteria reproduce.

- Use acrylic or spray paint to protect UV light.

When to work with professional services

Hobby printers do well in basic pots, but industrial-grade solutions ensure the accuracy and material versatility of complex projects. Greatis the leader of China’s rapid prototype companies, solving the limitations of desktop 3D printing:

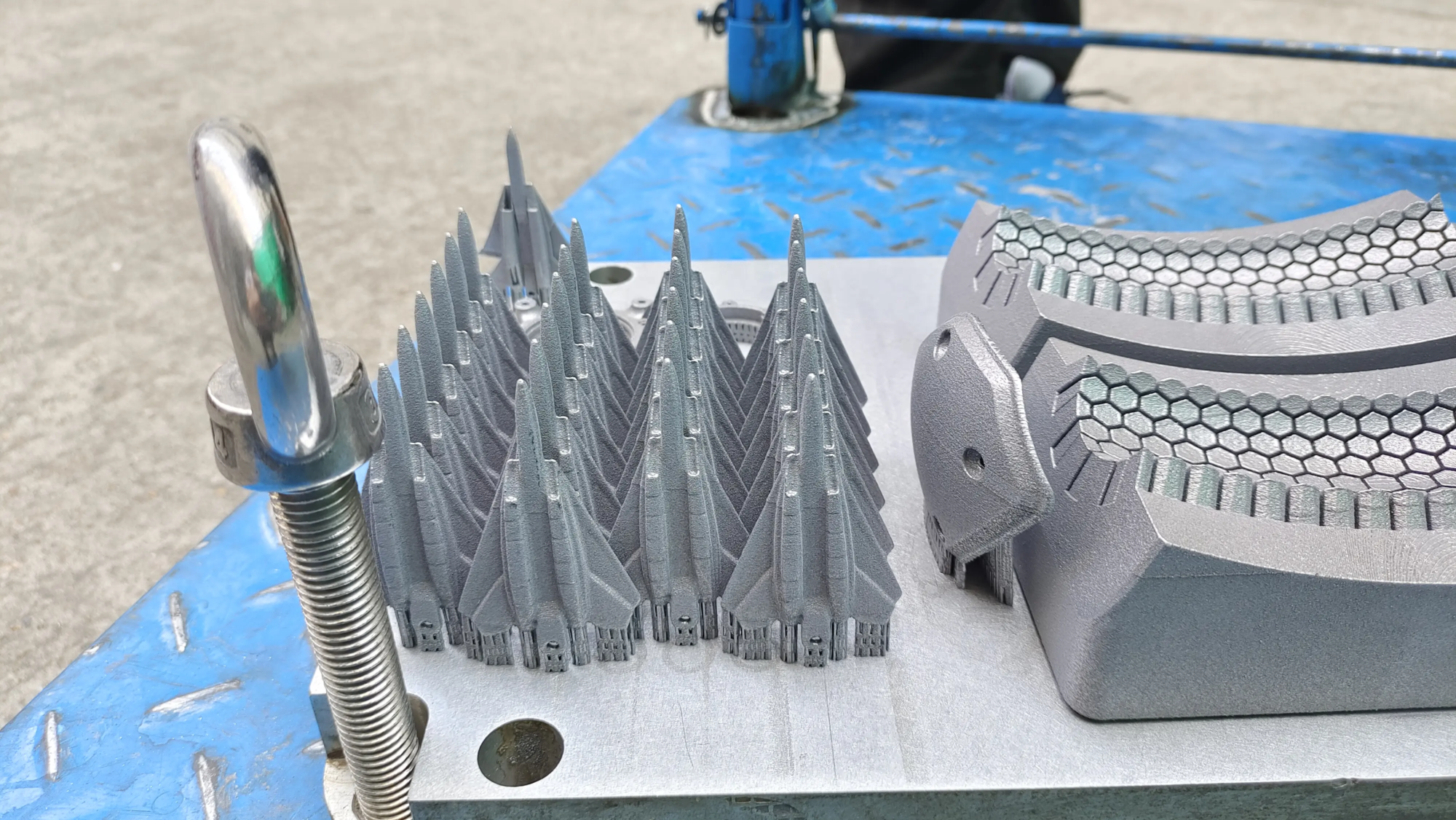

- SLM (Selective Laser Melting) Printer: Handmade pots in stainless steel, titanium or copper for avant-garde, weatherproof design.

- One-stop post-processing: Provide polished, electroplating (e.g., a gold-coated pot) or ceramic coating for aesthetics and durability.

- Scalability: Production of hundreds of identical units for commercial use with microscopic level of accuracy.

- Material expertise: Customized medical grade or anti-pressure materials for professional environments.

Example: The designer used Greatlight’s aluminum printing to create layered juicy murals and rust-free, structural debris that could not be achieved with plastic.

Real-world applications

- Modular Garden: Print stackable units for vertical green walls.

- Smart growers: Embedded soil sensors or irrigation passages in the design.

- Branded products: Business prints the pot of logo for eco-conscious promotion.

in conclusion

DIY 3D printed meat pots combine creativity, sustainability and technology to allow anyone to cultivate a custom indoor garden. Hobbyists can start with desktop printers and PLAs, while professionals who work on complex or large-scale projects benefit from industrial partners Great. Their advanced SLM printers and post-processing services transform the concept into a high-precision metal masterpiece – suitable for architects, brands or artists. Ready to innovate? Try a simple seeder today, or consult an expert to push the boundaries.

FAQ: 3D printed juicy pots

Q1: Is the 3D printing pot safe?

Yes, if sealed correctly. RAW PLA is non-toxic but porous. Coat the interior with waterproof resin to prevent bacterial growth and water leakage.

Q2: How long did the 3D printed pot last outdoors?

PLA lasts 1-2 years before biodegradation. For life, use UV-resistant PET or metal alloys printed through industrial SLM services.

Q3: Can I print the pot without drain holes?

Not recommended. Succulents need drainage to avoid root rot. If your design omits holes, add caution to the inner gravel layer and water.

Question 4: What is the cost difference between DIY and professional metal printing?

The cost of a DIY PLA pot is <$1. Greglight’s metal pans start at around $20 for small designs and can be used for premium durability, custom finishes or building uses.

Q5: How to design for larger succulents?

Ensure the wall thickness is ≥3mm to maintain stability. For 6-inch > 6-inch pots, use a triangular support structure or choose metal printing to prevent cracks.

Question 6: Can Greatlight print multi-mass pots?

Yes! Combine metal with embedded ceramic or glass inserts through hybrid fabrication to achieve unique textures and functions.

Q7: What file format is required for professional printing?

Submit .Step or .iges files for CAD accuracy. Greglight engineers optimize design during the citation process.