Embrace the magic inside: Make amazing DIY 3D printing Mickey ears

The iconic silhouette of Mickey Mouse’s ears is immediately recognized worldwide, symbolizing fun, nostalgia and Disney charm. Souvenir shops are packed with options, but personalized, unique Mickey ears have a special charm. The World of Input 3D Printing – A revolutionary technology that enables creators to design and manufacture custom accessories that have never been so before. This guide step in creating your own DIY 3D printed Mickey Ears, exploring the process from concept to finished, magical headdresses, while highlighting how professional services can enhance your project.

Why 3D Print Your Mickey Ears?

- Final Customization: Beyond the standard feeling. Design the ears shaped like your favorite characters, decorated with intricate patterns (such as small castles, fireworks, or constellations), scaled to any size, or even personalized with a name or date.

- Durability and material selection: 3D printed ears, especially through powerful materials such as SLM (selective laser melting), such as nylon, PETG and even metal, are more durable than fabric versions. They can resist rain, bumps and sunlight, making them perfect for frequent park visits or collector displays.

- Professional Completion Options: 3D printing allows for a variety of post-processing: smooth to satin finish, bright colors, metal quality or unique textures that can’t be achieved with traditional handmade high-end look.

- Perfect for: Design a headband that comfortably matches your specific head measurements for all-day wear comfort.

- Manufacturer satisfaction: Wear pride in something truly original, designed and brought you to life.

DIY Journey: From Pixels to Plastic (or Metal!)

1. Design Phase: Sketch your vision

- software: First, use Tinkercad or Fusion 360 (such as Thingiverse or Myminifactory) to start with platforms like existing ear and headband designs (respect copyright – make sure to allow personal use/modification).

- Main things to note:

- Proportion and proportion: Refer to existing ears. The standard width range is 10-14 cm. Unless you are intentionally designed to design alternatives, keep the classic round ear circle pattern.

- Attachment: How will the ears be secured to the headband? Design the corresponding features of slots, clips or screw holes on the ear and headband. Magnetic connections offer stylish, toolless options.

- Hollow and solid: Hollow internal ribs significantly reduce weight and material use, making them ideal for plastic printing. In very thin designs or in complex metal prints, solid structures may be required.

- Personalization: Merge raised or concave text, symbols, or patterns into the ear design itself.

2. Printing Phase: Bringing Your Design to Life

-

FDM (Fusion Deposition Modeling – Plastic):

- Suitable materials: PLA (Affordable, bright colors, easy), PETG (Stronger, more heat resistant/flexible), ABS (Strong but requires ventilation), TPU (Flexible headband for flexible filament).

- Key settings: Use enough support structure for overhangs (especially under the ears). Vertically eastward ears (minimize layer lines on the front face). Optimized fill density (15-30% is usually sufficient for hollow designs). Prioritize layer height to maintain smoothness (e.g. 0.15mm or lower).

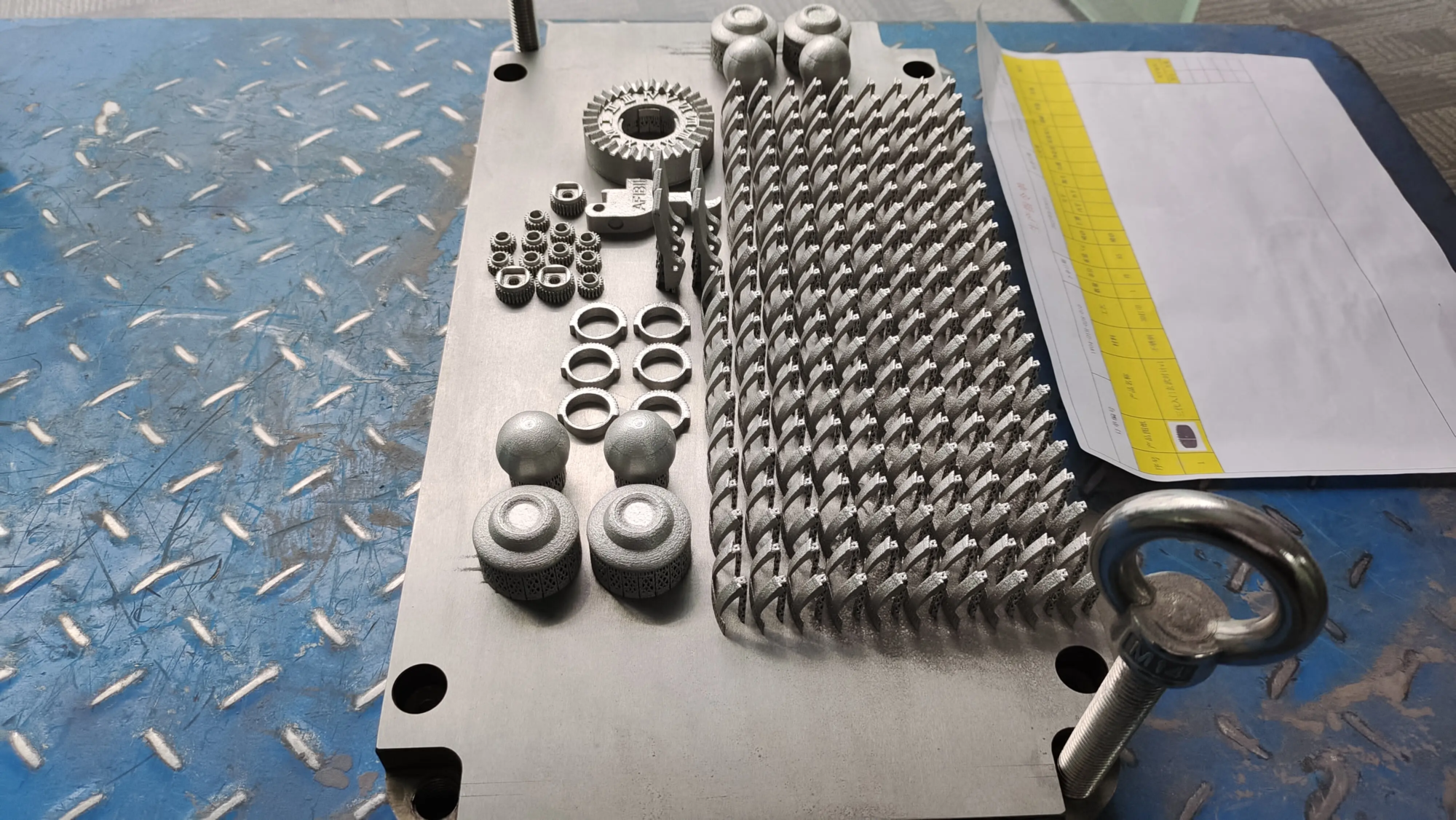

- SLM (Selective Laser Melting – Metal): For truly premium, durable ears

- Professional Edge: Here, like Greatlight Shins, work with expert manufacturers. SLM uses a powerful laser to fuse fine metal powder particles (such as stainless steel 316L, aluminum alloy, titanium) into one layer. result?

- Excellent durability: Unrivaled Strength and Resilience – Your ears become a potential heirloom.

- Complex details: SLM captures the exquisite design details and intricate geometric shapes of the FDM struggle.

- Metallic Glory: Real metal finishes (polished, matte, satin, gold/silver) with plastic wire.

- Perfect for professionals: Ideal for custom merchandise suppliers, performers or collectors, requiring absolute quality and point of difference accessories. Greatlight’s advanced SLM equipment and technical expertise ensures accurate and reliable results for metal prototypes and final parts.

- process: While Home Metal 3D printing is rare, send your final, optimized design files to providers like Greatlime. They handle complex printing processes, powder handling and necessary safety procedures.

- Professional Edge: Here, like Greatlight Shins, work with expert manufacturers. SLM uses a powerful laser to fuse fine metal powder particles (such as stainless steel 316L, aluminum alloy, titanium) into one layer. result?

3. Post-treatment and completion: Release professional polish

This stage converts the original print into the display accessories:

- Support removal: Carefully remove the special support used in FDM support structures or SLM metal printing.

- Grinding: Start with coarse sand (for main layer/support blocks) and then gradually move to fine sand (400+, up to 2000+) for a smooth finish. Wet sand prevents plastic dust. Metal printing allows for powerful support removal and surface smoothing.

- Start and Painting (FDM): Sprayer fills the microscopic lines. Use high-quality acrylic coatings. Sealed with a sheer jacket (matte, satin, gloss).

- SLM- Greatlight Specialty: This is a key value-added to professional services.

- Grinding and polishing: Achieve mirror finish.

- Media explosion: Creates a uniform satin or textured surface.

- Chemical polishing/electropolishing: Significantly enhances corrosion resistance and smoothness.

- Anodized (aluminum): Added vibrant durable colors.

- plating: Apply gold, silver, nickel or chrome finishes for real luxury.

- assembly: Secure the ears firmly to the headband. Powerful epoxy resin is suitable for plastics. Metal ears can be welded (professional recommendation), tightened (if designed for them), or bonded with high-strength metal adhesives. Make sure the headband is comfortable to fill.

4. Enjoy your creations!

Paint the final decorative touch (ribbons, glued trinkets back finishing). Your unique high-quality Mickey ears are ready to turn your head!

in conclusion

DIY 3D printed Mickey ears offer unparalleled creativity, personalization and satisfying craftsmanship. While FDM printing provides an accessible entry point for plastic ears in your home, the pursuit of truly premium, durable and very detailed ears (especially using metal) highlights the profound value of professional rapid prototyping services. The company likes it Great Bring advanced capabilities, such as industrial grade SLM Metal 3D Printing and comprehensive One-stop post-processing (Smoothing, polishing, electroplating, anodizing) Direct to creators and businesses. Have professional knowledge Quickly customize parts from a variety of materials and solve complexes Rapid Prototyping ChallengeGreatlight ensures that your custom ear design not only meets professional standards, it can surpass it. Whether you’re making or prototyping a product line for entertainment, embracing these technologies unlocks a whole new level of magic in personalized accessories.

FAQ: DIY 3D Printing Mickey Ears and Professional Services

Question 1: Can I legally sell 3D printed Mickey ears?

A: This is a key copyright consideration. The basic outline may be argueable, but using Mickey’s name, exact similarity, or trademark symbols are protected. Ears can usually be created for personal use or gifts. To sell them requires a clear permission from Disney. Focus on highly unique transformative designs, rather than directly copying Disney’s trademarks. If sold, be sure to consult official information or legal advice.

Q2: What is the best FDM silk for durable Mickey ears?

one: Petg Is the best choice for home printers: excellent layer adhesion, flexibility, waterproof/UV resistance and durability. Avoid brittle PLAs with treated wearable accessories. ABS is powerful but trickier and requires ventilation.

Q3: How to make my plastic FDM ears look smoother and more professional?

Answer: Invest time for post-processing:

- print: Use a smaller layer height (0.12-0.15mm) and carefully calibrate the printer.

- Grinding: Start rough (~120 particle size) and then work Gradually Down to very fine grit (1000-2000+). Wet helps. Consider filling the primer to fill the layer after initial grinding.

- painting: Multiple thin layers are better than a thick coat. Finished with a protective sheer jacket.

Q4: Why consider the metal of Mickey Ears (SLM)?

A: Metal ears provided Unrivaled durability, heavy duty premium feel and stunning metal finish (Polished, plating). They are perfect for high-end collectors, professionals (e.g., designated park guide guides) or prototypes of licensed merchandise. SLM allows for complex designs that are impossible with plastic. Although upfront costs are higher than FDM, its lifespan and unique appeal justify advanced applications.

Q5: What are the advantages of using a service like Greatlight for my printed ears?

A: Professional services offer the advantages of changing games:

- Material expertise: Enter engineering grade plastics and a variety of metals (stainless steel, aluminum, titanium).

- Advanced Technology: Industrial SLM printing for complex high-strength metal parts.

- Superior finish: Professional grade polishing, anodizing, plating and painting for perfection and durability.

- Accuracy and reliability: Professional equipment and expertise ensure consistent, highly critical parts.

- Volume and scalability: prototype and Proportional production is smoothly carried out in large quantities.

- Complexity of solution: They deal with design optimization, challenging geometry and the post-processing challenges you may face." Greatlight is especially good at One-stop solution From rapid prototype to finalization, the refined part, especially in metal. Customize your precision parts now at the best prices!

Question 6: How to secure the ears to the headband, especially for metal ears?

one: Design is the key! Function of directly embedded parts (best suitable for SLM printing accuracy):

- Screw Hole: Design match threaded holes in the ears and headbands. Use small stainless steel screws.

- Embedded magnet: Design a cavity of a strong, new magnet in both sections for seamless tool-free connection. Use super glue or epoxy for extra safety.

- Cemented high strength adhesive: For the final bond, use a special metal adhesive or a high-strength epoxy designed for metal/plastic bonding. Always carefully clean the surface before bonding. Professional welding is an option for all-metal components, but requires specialized equipment.