The Ultimate DIY Guide to Making a 3D Printed Ring Sizer (Accurate, Affordable, and Customizable!)

Finding the perfect ring size can be a frustrating guessing game, especially when ordering online or having custom jewelry made. Purchasing multiple ring sizers or visiting a jeweler adds cost and inconvenience. What if you could make an accurate, reusable ring sizer at home? Enter 3D printing—A versatile technology that allows you to affordably design and build professional-grade tools. This guide will walk you through creating your own ultra-accurate DIY ring sizing guide.

Why 3D print a ring sizer?

- High cost performance: Dozens of sizers can be produced from a single spool of filament at a cost of just pennies per unit compared to commercial alternatives.

- High precision: Through careful design and calibration, tolerances below ±0.1mm are achieved, complying with professional standards.

- custom made: Design sizers with unique features: integrated size markers, ergonomic handles, custom designs or multiple international conversions.

- Auxiliary functions: Create sizes rarely found in standard suits (half sizes, wide).

- Durability: PLA+ or PETG filament provides long-lasting, chemical-resistant tools.

Step by step: Create your ring sizer

-

Get or design a digital model:

- Option A: Download reputable templates: Platforms like Thingiverse, Printables or Cults3D offer free designs. Look for models with good ratings, calibration instructions, and accuracy records.

- Option B: Design your own: Use CAD software (Tinkercad for beginners, Fusion 360 for advanced users). Design round rings corresponding to standard ring sizes (US, UK, EU). Crucial: Include resin-printed escape holes or consider FDM-printed gaps to prevent suction issues. Embed dimension markers directly into the model.

-

Material selection and printer preparation:

- Filament recommendations: PLA or PETG have excellent dimensional stability and are easy to print. Avoid using flexible filaments (TPU) as they can bend and affect measurements.

- Printer calibration: Basic! Make sure the printer bed is perfectly level. Perform extrusion calibration (e-steps) and flow adjustments. Precise dimensional printing requires meticulous calibration.

-

Optimize slicer settings to improve accuracy:

- Lower level height: Use 0.15mm – 0.2mm layers for a smoother surface and finer mark detail.

- 100% filled: Eliminates internal voids that can cause deformation under pressure or offset measurements. For resins, solids are standard.

- Horizontal expansion: Fine-tune this setting (e.g., -0.05mm adjustment) to account for filament expansion and achieve precise inner diameter.

- Slow peripheral speed: 30-40mm/s improves dimensional accuracy and wall thickness consistency.

- Minimize support: Cleverly designed to avoid bracing on surfaces of critical dimensions. Use tree supports sparingly if needed.

- Brim/raft: Used to provide better bed adhesion on small, round objects that are easy to lift.

-

Printing and post-processing:

- Monitor the first layer closely – ensure perfect adhesion.

- Remove the supports gently to avoid scratching the styling surface.

- calibration: This is mission critical! Use digital calipers to carefully measure the printed ring. Compare with nominal dimensions. Note any average deviation (± tolerance). Apply this offset to the slicer settings (horizontal expansion) for future printing. Make note adjustments based on filament type/brand.

- Use the 3D printed ring sizer:

- Fit test: The ring should slide over the sizer snugly But without force. It shouldn’t feel tight or fall off easily.

- method: Start with a small size and work your way up until the ring slides smoothly over the size pegs. Dimensions for correct fit correspond to printed markings.

- environment: Measure on your finger at room temperature (cold fingers will shrink!). Avoid measuring when there is swelling (after exercise, high temperature).

- bandwidth: Consider matching the sizer width to the actual ring width for the most accurate assessment.

Beyond DIY: When precision matters most

While DIY prints are great for hobbyist ring guides, Professional manufacturing becomes crucial For applications requiring unparalleled precision, material performance or aesthetic finishes:

- End use function loop: Everyday wear rings require durable, biocompatible materials (e.g. titanium, stainless steel, precious metals) and processed by advanced SLM/DMLS metal 3D printers, which are well beyond the capabilities of FDM/desktop resins.

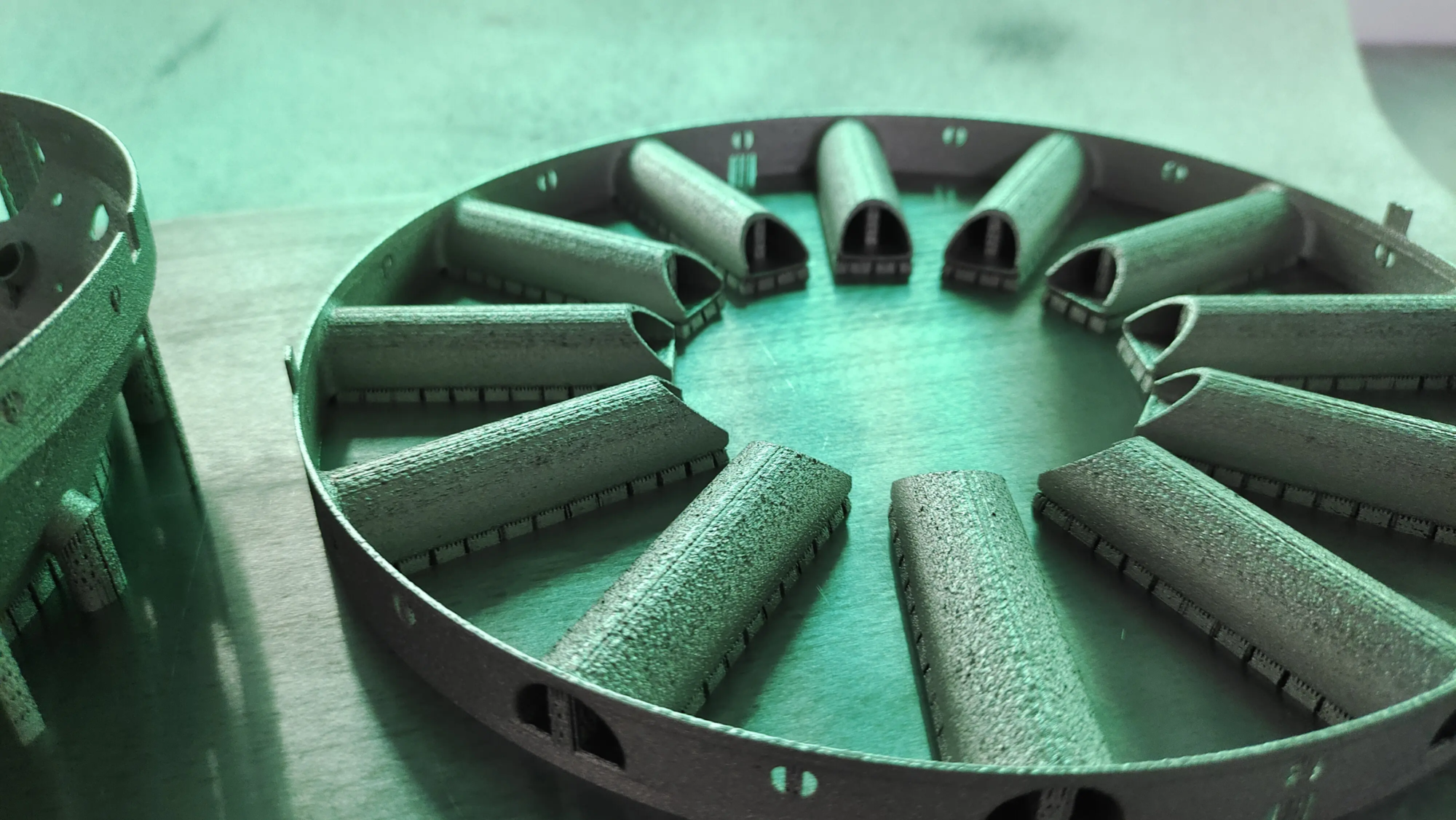

- Master Jewelers and Casting Models: Production-grade ring dies for casting require ultra-smooth surfaces and near-zero tolerances achieved through specialized SLS/SLA resins and specialized post-processing.

- Complex geometries/metals: Intricate filigree, embedded gemstones or thin-walled designs require the precision of an industrial printer and the versatility of materials.

- Mass production and finishing: Obtaining production-ready surfaces (polishing, plating, engraving) requires integrated post-processing services.

This is where working with experts like GreatLight can bring transformative value. ✨

as a leader Professional rapid prototyping, huge light lever:

- Industrial grade SLM/DMLS metal printer: Perfect ring prototypes and end-use parts for titanium, stainless steel, aluminum and precious alloys.

- Multiple technical expertise: Complement metal additive manufacturing with advanced SLS, SLA, CNC machining and injection molding for complex ring/jewelry projects.

- Engineering-led support: From design optimization (DFAM – Design for Additive Manufacturing) to material selection for functionality and comfort.

- Comprehensive post-processing: Mirror polishing, vibration polishing, electroplating (gold, rhodium, nickel), laser engraving, heat/freeze treatment and assembly.

- Full production: Seamlessly scale prototypes to small batches or large-scale production runs under strict quality control.

in conclusion

Create your own 3D printed ring sizing guide to affordably unlock personalized jewelry sizing at home. By focusing on meticulous printer calibration and optimized microtome settings, hobbyists can achieve surprisingly professional results. It embodies the empowering spirit of desktop 3D printing.

However, realize the limitations of DIY. For functional jewelry prototyping, complex end-use rings requiring biocompatibility, unparalleled surface finish, or scalable manufacturing, Entrust experts like Ferrite to ensure industry-leading quality. Our advanced SLM metal printing and integrated finishing bring complex ring designs to life efficiently and reliably. Ready to move beyond prototyping?

Get an accurate quote today and experience the difference professional rapid prototyping makes. Visit Gretel now!

FAQ: DIY 3D Printed Ring Sizing Guide

Q: How accurate are DIY ring sizers?

A: With diligent printer calibration (bed leveling, E-step), optimized slicer settings (low layer height, 100% infill, careful adjustment of horizontal expansion), and post-print verification using digital calipers, experienced manufacturers can usually achieve within-range accuracy. ±0.1mm to ±0.15mm. This is comparable to many commercial plastic applicators.

Q: Which material is best for ring sizers?

one: People’s Liberation Army is the easiest to obtain and print. polyethylene terephthalate Provides higher temperature resistance and toughness. Both have low shrinkage and good stiffness. ABS should be avoided due to the risk of warping, while TPU/Soft PLA should be avoided as a measurement tool due to flexibility.

Q: Do I need support?

Answer: Usually No Standard ring sizer for vertical printing. Designs with protruding handles, complex bases, or wide gaps may require minimal support (tree supports are preferred). Ensure supports do not contact critical dimension surfaces. Resin prints require strategically placed support structures.

Q: How do I calibrate the print applicator?

A: Print multiple key sizes (e.g. US sizes 5, 7, 9). Measurement Inner diameter (ID) Carefully in multiple places Digital caliper. Calculate the difference from nominal dimensions (± tolerance). Apply this offset using “Horizontal expansion” Set in slicer (negative values shrink, positive values expand) and reprint/test. Repeat until consistent accuracy is achieved. Different filaments may require different settings.

Q: Can I print wide-band sizing mandrels?

Answer: Yes! Design thicker rings (~5mm+) or cylinders with grooves/ridges corresponding to size to accommodate wider rings. Ensures excellent bed adhesion on tall and narrow objects. Consider adding a base plate for stability.

Q: Why choose GreatLight over DIY for actual ring prototyping/production?

A: GreatLight offers features not possible with desktop printers:

- Industrial metals: Print biocompatible titanium, stainless steel, and gold alloys via SLM.

- tolerance: Achieve ultra-tight tolerances as low as ±0.025mm.

- Premium finishes: Medical/skin grade polishing, jewelry plating (gold, rose gold, rhodium), texture creation.

- Materials and design expertise: Design to optimize strength, wear, casting fit and manufacturability.

- Scalability: Seamlessly connect prototyping to proven production volumes.

Q: How long do DIY PLA ring sizers last?

A: When stored properly away from heat or solvents, PLA sizing maintains dimensional stability and functionality Year. Exposure to moisture may cause gradual degradation over 2-5 years. PETG provides long-term resistance. Obviously, a professional metal size measuring instrument can be used indefinitely.