introduce

Imagine having a one-of-a-kind robot action figure crafted directly from your imagination—without the constraints of mass production or compromises on design. With the help of 3D printing, enthusiasts and creators can now bring futuristic heroes and mechanical warriors to life in stunning detail. DIY 3D printed robot action figures blend artistry, engineering and personalization to revolutionize the way we interact with collectibles. As this trend takes off, understanding the entire process from concept to finished product can unlock endless creative possibilities. Let’s dive into this exciting world where your workshop becomes an innovation factory.

Why 3D printing is revolutionizing puppet creation

Gone are the days when Tangshan’s styling was limited to customization. 3D printing gives creators unparalleled freedom:

- Design flexibility: Software like Blender or Fusion 360 can achieve complex robot joints, armor textures, and dynamic poses that are impossible with traditional sculpting.

- Accessibility: Desktop FDM printers (for beginners) produce affordable plastic prototypes, while resin SLA printers enable ultra-fine details like circuit patterns or rivets.

- iterative prototyping: Quickly test articulation, balance and aesthetics by reprinting parts overnight – perfect for perfecting access compatibility for movable limbs or magnetic weapon mounts.

From independent designers to fans recreating vintage mechas, 3D printing is democratizing the production of high-quality collectibles.

Step by Step: Make Your Own Robot Action Figure

1. Conceptualization and Design

Start with a sketch or digital mood board. Define your robot’s legend: Is it a stealthy Scout or a Heavy Titan? Use Tinkercad to create simple shapes, or ZBrush to create organic-mechanical hybrids. Optimize the printability of your model:

- Avoid overhanging more than 45 degrees.

- Interlocking joints (ball and socket, hinges) designed with tolerances of 0.2–0.5 mm for smooth movement.

- Individual components (head, arms, weapons) for multi-material printing.

2. Printing process

- Filament selection: PLA is convenient; PETG is durable; TPU is used for flexible parts such as clamps.

- set up: The layer height is 0.1mm–0.15mm to ensure clear edges. Use trees to support complex geometric shapes.

- Post-processing: Sand the layers, apply filler primer, and assemble the parts with glue or dowels.

3. Finishing work

Airbrush acrylic paint for gradients, dry brush metallic paint for weathering, and sealed with matte/gloss varnish. Add LED wiring to make eyes or thrusters light up!

Materials matter: from plastic to metal

While plastics dominate DIY projects, metal parts elevate the numbers to a professional level. Metallagen provides heavy-duty realism and structural integrity to load-bearing joints or armor. That’s the beauty of working with an expert. For example:

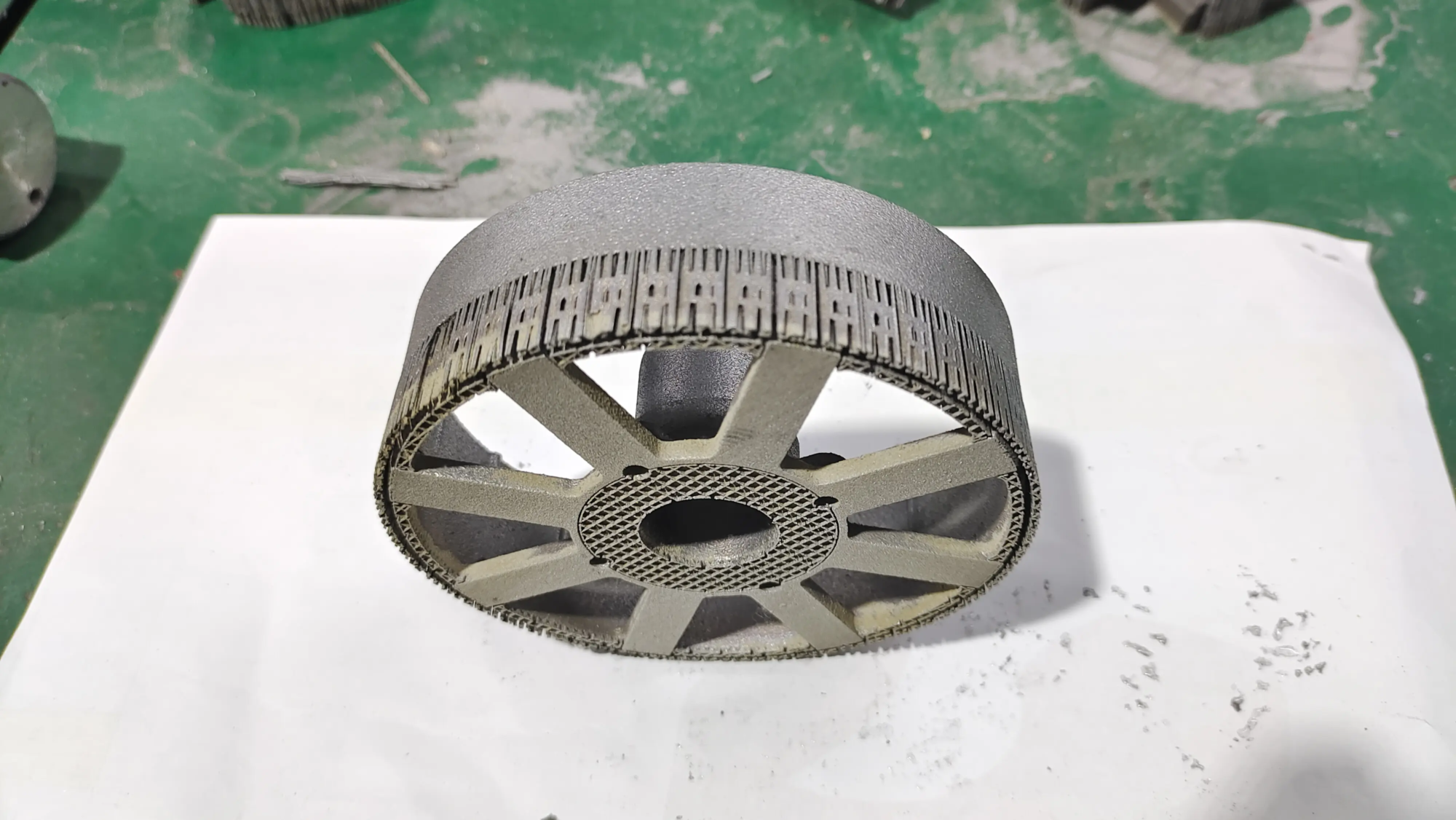

GreatLight specializes in metal prototyping using Selective Laser Melting (SLM), a high-precision 3D printing technology that uses lasers to bond layers of metal powder. Their SLM printers can process stainless steel, titanium or aluminum parts, making them ideal for articulated robot frames or decorative elements. In addition to printing, they also handle CNC machining, polishing and coating, transforming raw prints into exhibit-ready exhibits.

Metal integration solves common DIY pain points:

- Durability: Steel joints can withstand repeated poses without cracking.

- aesthetics: Anodized titanium metal allows for an iridescent effect that paint cannot achieve.

Overcoming Challenges: When to Consider Professional Services

There are some obstacles to DIY printing: support failure, deformation, or stiff joints. For steel complex metal assemblies or tight deadlines, industrial-grade solutions ensure success:

- precision gears: SLM-printed titanium gears enable silky-smooth limb joints.

- scale consistency: Professional calibration ensures that the components of multiple character 3D models are consistent.

- hybrid build: Combines a self-printed plastic exterior with GreatLight’s custom metal interior – the best of both worlds.

If your project requires aerospace-grade materials, microscopic tolerances (as tight as ±0.02 mm), and overall, rapid prototyping services can bridge the gap between imagination and execution. Companies like GreatLight handle the technical heavy lifting, leaving creators to focus solely on design.

Unleashing Creativity: Customization and Beyond

The real magic is in personalization:

- Modular kit: Design weapon exchange systems or reversible components.

- augmented reality: Embed NFC chip to trigger digital animation through application.

- community cooperation: Share STL files on platforms like Thingiverse to remix other people’s designs for unique variations.

With services ranging from tungsten exoskeletons to ceramic details, your robot’s complexity is limited only by vision.

in conclusion

DIY 3D printed robot action figures represent a seismic shift in creator culture—merging art with cutting-edge manufacturing. Whether you print at home or work with professional prototypes, this blend of technology and passion delivers unrivaled culturally personalized collectibles. With tools like SLM printing now available through partners like GreatLight, the barrier between a hobbyist’s dream and an industrial-grade masterpiece disappears. So fire up your printer, draft your mech design, and remember: in this age of custom creation, you’re not just building a character, you’re designing a legacy.

Frequently Asked Questions (FAQ)

**1.Can I