introduce

Imagine walking into your entrance and seeing the shoes perfectly organized – no more piles, no crazy search for match pairs. Creating a custom shoe rack that suits your space and style has never been easier with 3D printing. Whether you’re an amateur for desktop printers or exploring industrial solutions for large projects, this guide dives into building durable, scalable DIY shoe racks. We will cover design principles, material selection, structural skills, and even professional rapid prototyping services. Great Can improve your project.

Why 3D printed shoe rack?

Traditional shoe racks usually come in fixed sizes and designs, but 3D printing offers the advantages of changing the game:

- custom made: Tailored to fit tight corners or unique shoe collections (e.g. high heels and sneakers).

- Modular: Design stackable parts to expand storage as needed.

- Cost-efficiency: Avoid retail markings – Small shelves cost less than $20.

- Sustainability: Use recyclable thermal plastics such as recyclable filaments or PETG.

Additionally, 3D printing gives quick iteration: test prototypes overnight without the need for expensive tools.

Key Design Considerations

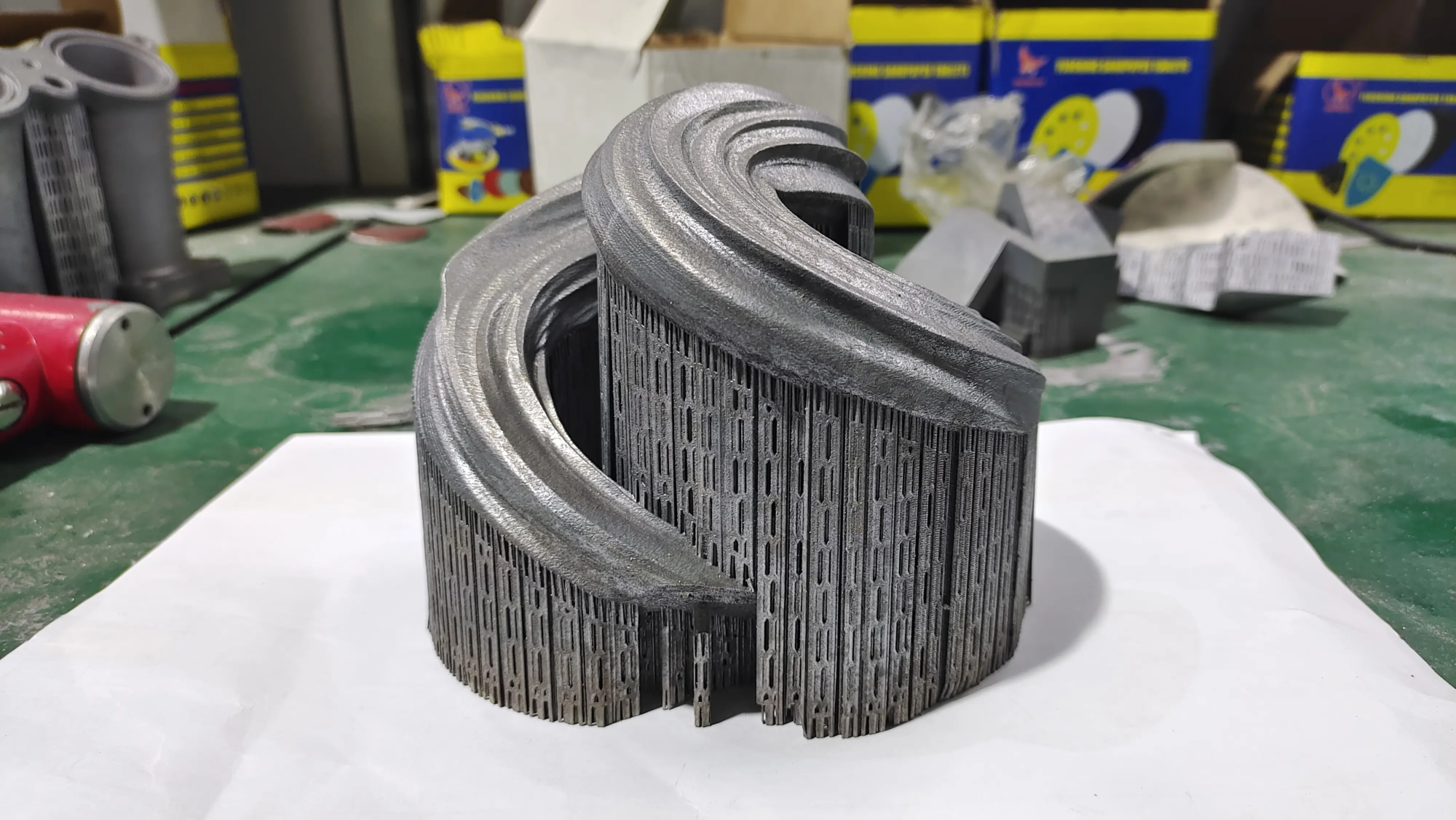

1. Carrying geometry:

Shoe racks must support 5-10 kg per rack. Integrate these features:

- Triangular support Rigid on joints.

- Rib or honeycomb filling Vertical support (15–30% density).

- Interlocking slots For friction-based components (no glue required!).

2. Material selection:

- PLA: Affordable and easy to print, but degraded in sunlight. Ideal for indoor racks.

- PETG/Pets: Provides UV resistance and flexibility. Wet areas are preferred.

- TPU: Used to support feet or flexible dividers.

For fire assessment or industrial applications, Nylon or polycarbonate (Printed via SLS) is the best – professional grade equipment is required.

3. Print settings for persistence:

- Layer height: 0.2-0.3 mm to maintain balance of speed and strength.

- Walls/circle: At least 3 layers to prevent splitting.

- direction: Print parts flat to maximize layer adhesion.

- annealing: Heat treatment of PLA at 110°C for 30 minutes to improve impact resistance.

Step by step building guide

(Tools required: 3D printer, caliper, CAD software, sandpaper)

Step 1: Measurement and Design

Calculate the internal dimensions based on the shoe size (average: 30 cm deep x 40 cm wide). Use parameter software like Fusion 360 to adjust variables (e.g. height or width) globally.

Step 2: Model Components

Design modular parts:

- Substrate: Embed non-sliding TPU pad.

- Vertical support: Add dovetail seam joints to stack.

- shelf: Includes ventilated drainage holes.

👉 Pro Tip: Easy to insert on a 10° angle rack.

Step 3: Printing and Post-processing

- The wall thickness near the slice archive increases.

- Sand edges for smoother assembly.

- Apply acrylic spray coating to waterproof PLA/PET.

Step 4: Assembly

Use the designed connectors to merge the components together. Anchored to the walls, including mounts for seismic safety.

Strengthen your shelf with professional services

DIY projects thrive in creativity, while complex designs often require industrial-grade solutions. That’s where Rapid prototyping Good at it. As a leader Selective laser melting (SLM) 3D printingthey provide:

- Metal Prototyping (Stainless steel, aluminum alloy) for fire or outdoor racks.

- One-stop post-processing: Precision processing, smooth or powder coating.

- Material flexibility: Medical grade resin, carbon fiber composite or custom alloy.

- speed: Produce functional prototypes in 48 hours or less.

Whether you are a stand that requires load testing or a full-size stand with moving parts, outsourcing to bridge the gap between hobby experimentation and commercial-grade durability. Their expertise ensures that your design survives the stress of the real world, saving time and material waste.

in conclusion

Build a 3D printed shoe rack combined with creative expression to transform a overcrowded closet into a streamlined space. From adaptive modular shelves to smart materials hackers, the project demonstrates how additive manufacturing can democratize home design. For ambitious build desktop printers, work with experts Rapid prototyping Unlock metal perseverance and tailor-made finishes. Are you ready to be clean and tidy? Start the printer or CAD software and enter an organized life.

FAQ

Q: How long does it take to print a 4-layer shelf?

A: Use a standard FDM printer, it is estimated to be 15-25 hours in total. Use a 0.3mm layer and multiple parts per board to cut significantly.

Q: Can I print shelves outdoors?

A: Only weather-resistant materials, such as ASA or PETG. For permanent use of outdoor use, consider stainless steel with SLM printing.

Q: What if my printer’s build board is too small?

Answer: Use modular printing "ceramic tile" With puzzle joints. Industrial SLS services like Greatlight’s can produce oversized components in one piece.

Q: How much weight can a PLA rack hold?

A: Correctly designed (5 walls, 30% fill), each shelf can hold up to 8 kg. Strengthen the vertical columns of higher shelves.

Q: Will color affect strength?

A: No – The dent will not change the integrity of the polymer. However, black/white filaments usually have stricter quality control.

Q: Can I modify the design in the future?

Answer: Absolutely! Parameter CAD files allow you to resize the shelf immediately. Greatlight also supports iterative prototypes for complex updates.

Customize your precision parts now Great– Build tomorrow’s solution, one layer at a time. Request a quote or discuss material options [Your Website Link].