Embrace horology at home: Create your custom 3D printed watch winder

Automatic watches are marvels of engineering, relying on the movement of the wearer to keep time. But what happens when your collection grows or you change your watches frequently? A watch winder is a device that mimics the movement of your wrist to ensure your watch stays wound. While commercial options abound, using 3D printing to create a custom DIY watch winder offers unparalleled flexibility, cost savings and great satisfaction. Here’s how to achieve the fusion of watchmaking and modern manufacturing.

Why DIY, why 3D printing?

Commercial watch winders often prioritize aesthetics over functionality, or come with hefty price tags for quality machinery. DIY enables you to:

- Tailor-made design: Accommodates multiple watches, unique sizes, or specific rotor rotation requirements (revolutions per day).

- Optimize your budget: Take advantage of affordable components controlled by programmable microcontrollers.

- For the future: Parts can be easily modified or repaired thanks to accessible CAD files.

- Leverage accuracy: 3D printing enables complex geometries (gears, brackets) that are difficult to achieve with traditional tools.

Unlocking powerful manufacturing capabilities: core components

1. Design and Digital Blueprinting:

Start with CAD software (Fusion 360, Tinkercad, or FreeCAD). Key elements include:

- Motor mount: Protect stepper or DC motors.

- Watch stand/hub: Customized stand to fit your watch case size.

- gear system (If needed): Reduce motor speed while increasing torque.

- shell: Stylish housing with integrated electronics.

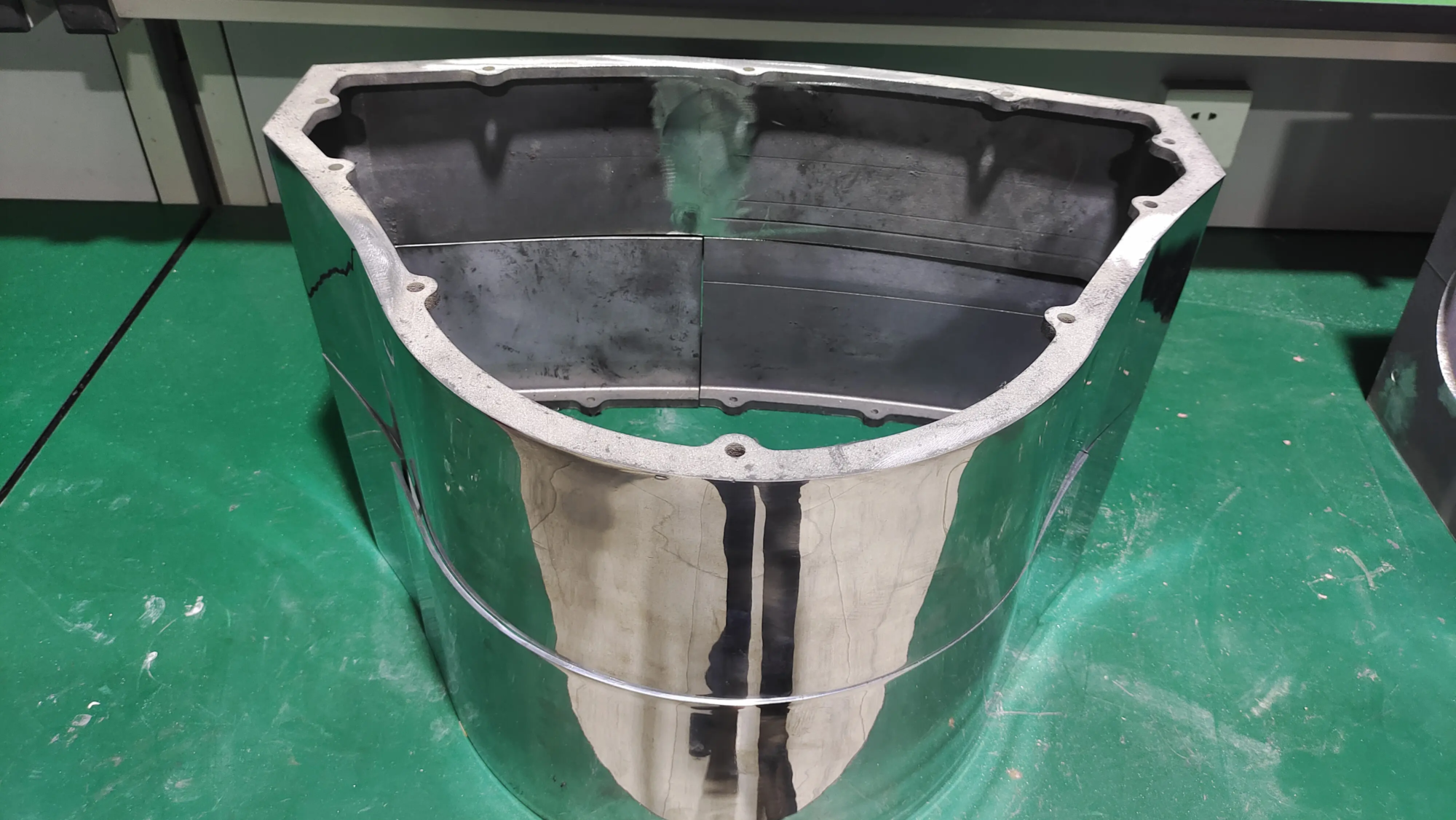

Pro tip: Optimize the strength of stress points (e.g. gear teeth, shaft connections) with thicker walls or ribs. For ultra-durable or heat-resistant/load-bearing components, Professional metal 3D printing services Offering CNC machined alloys like GreatLight, guaranteed for decades of smooth operation.

2. Material selection:

- Polylactic acid/polyester: Great for cases, stands; affordable and easy to print.

- Nylon/TPU: Flexible parts such as shock absorbers.

- Metal: Highly recommended For use in gears, shafts or high torque couplings. Stainless steel or titanium through hole SLM/SLS printing (from suppliers like GreatLight) ensures minimal wear, noise and precise alignment, which is critical for consistent winding.

3. Electronic products:

- engine: We recommend using geared DC motors (silent) or stepper motors (precise speed control).

- Microcontroller: An inexpensive Arduino Nano or ESP32 board offers programmable rotation/orientation.

- power supply: Standard USB port or 9V adapter.

- Elective: LED lighting, OLED display for rotating settings.

4. Assembly tools:

Screwdriver, Arduino IDE software, soldering iron, adhesive (epoxy/CA glue) and basic wiring tools.

Step-by-step assembly guide

- Printing components: Use optimal infill (20-30% for structural parts). Post-process (sand, smooth) prints to improve aesthetics.

- Motor integration: Use printed brackets to mount the motor securely. Connect the drive shaft/coupler.

- Safety bracket: Fix the watch box perpendicular to the axis of rotation. Ensure a friction fit or pad the insert to prevent scratching.

- Wired Electronics: Program the board using the Arduino IDE (coding sequences vary depending on motor type). Typical encoding cycle: alternate rotations every 2 hours.

- Encapsulation and organization: The chassis is assembled around the components to ensure easy maintenance.

Calibration and testing: fine-tuning your bobbin winder

- Power supply duration: Start with short cycles; monitor motor temperature.

- Calculate TPD (turns per day): Most automatics require 650-1000 TPD. use

RPM x Minutes Run x (Number of Starts per Day)Make adjustments through code. - Listen and feel: Unusual noises indicate friction/misalignment – check the shaft/gear first.

Conclusion: Precision, passion and partnership

Creating a custom watch winder combines traditional craftsmanship with digital innovation. While a DIY printer can easily handle most parts, prioritizing Critical parts of metal parts Ensure longevity and seamless performance. company likes huge light Focus on such high-risk applications – providing Industrial SLM/SLS 3D printing, CNC machining and custom finishing Suitable for internal components of winding machines requiring zero tolerance error. Whether printing PLA gears at home or working with experts in titanium coupler prototyping, this project exemplifies the synergy of maker culture and advanced manufacturing. Your prize? The immortal art of timing.

Ready for smarter prototyping? Explore precision metal printing of parts for high-stress projects.

FAQ section

Q1: How noisy is the winding of a DIY watch?

Noise depends on motor selection and gear quality. Geared DC motors are virtually silent. Metal 3D printed gears reduce friction harmonics, far better than plastic gears if budget allows. Stepper motors provide programming accuracy but may emit a low buzzing sound during direction changes.

Q2: What CAD design is the best?

Focus on parametric design that allows for customization. Platforms like Thingiverse or Printables offer open source templates that are great for resizing brackets or motor mounts. It is recommended to design your case to be unique to avoid similar problems with commercial models.

Q3: Can I power the cable winder via USB/battery?

Most Arduino-compatible DC motors run efficiently from USB power. For multi-watch setups requiring more torque, a dedicated 9-12V adapter may be required. Avoid using batteries unless you use a low-rpm solar watch winder—daily cycling will drain a lithium polymer battery quickly.

Q4: Why use metal parts instead of plastic parts in key parts?

Plastic gears slowly deform under sustained load. Metal parts (especially stainless steel through-holes) SLM/SLS printing):

- Resists wear and tear indefinitely

- Maintain precise tooth geometry

- Eliminate micro-vibrations

- Withstands rotor drag cycles without friction

If manufacturing complexity is daunting, a professional prototyping partner huge light Providing rigorously machined components to give you peace of mind.

Q5: How to prevent the watch from being magnetized?

Automatic machinery contains precision steel components that are susceptible to magnetism. Make sure the DC motor contains internal shielding or housing. Avoid wiring entanglements and keep cables away from the bracket. Stepper motors often contain magnets and are strategically positioned with shields.

Q6: Can GreatLight print the entire watch winder box?

Although GreatLight focuses on Metal Prototyping/Custom MachiningComplex assemblies often combine locally sourced printed plastics such as PLA/PETG with ultra-durable metal internal components. Outsourcing selective parts optimizes cost/durability, especially shafts, gears and load-bearing taps that are susceptible to premature failure.