Blog Post: Build Your Ultimate DIY IKEA 3D Printer Desk – Organized, Affordable, and Professional-Grade Quality

introduce

As 3D printing enthusiasts, we know the struggle: tangled spools of filament, stray tools, and a printer sitting on a rickety table. A dedicated workspace isn’t just a luxury, it’s essential for precision, safety, and sanity. Enter IKEA, the paradise of modular DIY solutions. In this guide, you’ll learn how to transform off-the-shelf IKEA components into a stylish, fully functional, efficiency-optimized 3D printed desk, while getting professional-grade insights from industrial prototyping experts. Whether you’re a hobbyist or a low-volume creator, this build balances cost-effectiveness with industrial smarts.

Why choose IKEA?

IKEA’s ecosystem of tables, cabinets and accessories offers unparalleled flexibility:

- Modular: Mix and match parts as your printer count grows.

- Vibration stability: Heavy-duty tabletop suppresses resonance for clearer printing.

- Cable management: Built-in solution keeps wires off the floor.

- budget friendly: Get a professional setup for under $200.

DIY Blueprint: Step-by-Step Assembly

Materials required:

- Desktop (option)

- Lin Meng 78": Affordable particle board. Avoid placing the heated bed directly on an untreated surface – use a heat-resistant pad.

- Kirby Walnut Countertop(74"): Solid wood has excellent stability and beauty.

- Support Base (select one)

- ALEX chest of drawers (x2): Provide tool storage and fixed desktop.

- ADILS legs(x4-6): Suitable for open floor designs (with shelves in the middle to ensure rigidity).

- Accessories

- SIGNUM cable organizer: Installed under the table for routing power cords and USB cables.

- SKÅDIS pegboard: Wall-mounted filament holder, nozzle and caliper.

- KALLAX shelving unit: Side storage for resin or print parts boxes.

Assembly process:

- Prepare space: Measure your room. Allow 35" Clearance between printer door and ventilation.

- frame base: If using ALEX units, keep them 55-60 inches apart. Use rubber pads to secure legs or cabinets to the underside of the tabletop to eliminate vibrations.

- Prioritize ergonomics: Install the main printer at eye level using a lift stand. Place the filament spool in a higher position (gravity feed minimizes extruder strain).

- cable prison: Clamp all wires into the SIGNUM rail. Use sticky clips to secure loose lines to keep the rollers clear.

- storage hacker:Hang SKÅDIS active filament holder. Store spare PLA/PETG in a sealed box inside a drawer (avoid a humid attic!).

Professional grade upgrade

In addition to the basics, industrial design principles are incorporated:

- Anti-static floor mat: Ground the printer and collect debris.

- shell: Use simple plexiglass panels to control smoke and regulate room temperature.

- IoT integration: Install a smart plug in the ALEX drawer and control the printer via WiFi.

A professional touch: When DIY reaches its limit

For creators who pursue Long-lasting, industrial-grade prototypingadvanced solutions become non-negotiable. This is where our team is huge light Bridging the gap between DIY setups and professional manufacturing needs:

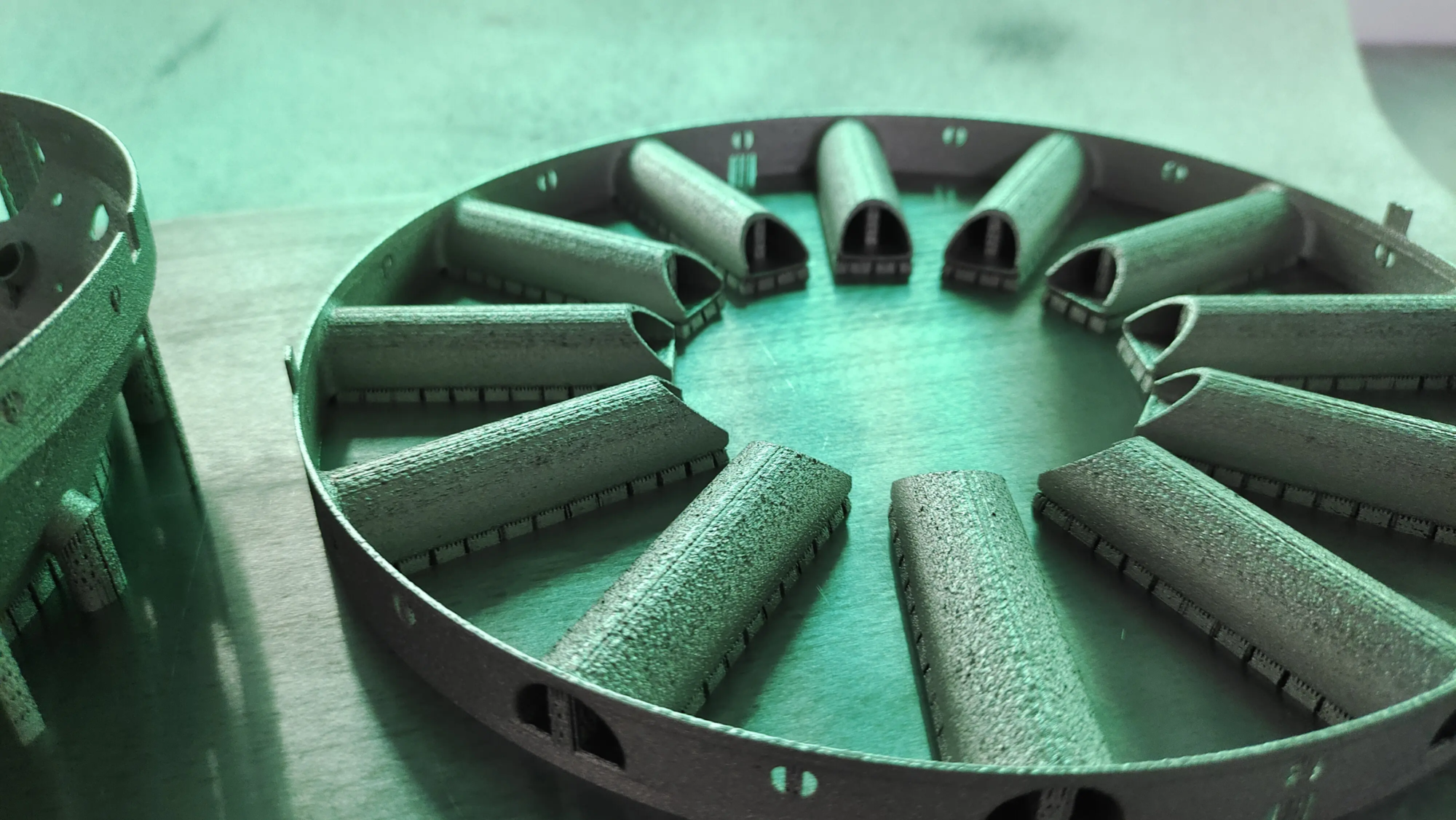

- Metal prototyping: Desktop FDM printers excel on plastics, but for complex aerospace parts? This is the field of SLM (Selective Laser Melting).

- One-stop precision: From prototyping to post-processing (machining, annealing or surface coating), GreatLight offers certified titanium, Inconel® or aluminum metal parts.

- speed and scale: Need to make 50 custom turbine blades in 4 days? Industrial SLM prints layers thinner than a human hair at unparalleled throughput.

in conclusion

The IKEA 3D printed desk is more than just furniture, it’s a launching pad for innovation. For less than $250, you can build an organized hub that eliminates clutter and optimizes your workflow. DIY empowers originality, while professional-grade manufacturing elevates vision into tangible form