Unleashing Precision: Mastering Dremel PLA Filament for Perfect 3D Printing

PLA filament remains the material of choice for hobbyists and professionals alike, prized for its ease of use, biodegradability, and vibrant color options. When you use a trusted brand like Dremel PLA, you have a solid foundation. However, even high-quality filament requires expertise to unlock its full potential. Based on advanced manufacturing insights honed through industrial-grade SLM 3D printing and precision prototyping, here’s how to optimize your Dremel PLA prints and avoid common pitfalls.

Why your method is more important than the filament itself

Dremel PLA is known for its consistent diameter and quality control, eliminating the variables inherent in budget filament. However, successful printing depends on an understanding of material behavior. PLA shrinks and warps less than materials like ABS, but it is sensitive to thermal management and moisture. At GreatLight, we utilize cutting-edge SLM (selective laser melting) technology to manufacture metal parts, but core principles of materials science translate across technologies: control, precision, and process optimization are critical.

Essential Dremel PLA filament tip for impeccable results

-

Silent Enemy: Moisture Control

PLA readily absorbs moisture from the atmosphere, resulting in blistering, poor adhesion between layers, and brittle, brittle final parts. Dremel PLA arrives vacuum sealed and contains desiccant – please respect this packaging before use.

- action: Store opened filament in an airtight container with a fresh desiccant pack. For critical prints or humid environments, consider drying briefly before printing (4-6 hours at 45-50°C in a dedicated filament dryer or food dehydrator). Avoid using the oven – temperature control is imprecise.

-

For perfect melting: temperature optimization

Every consumable and printer has its own "Goldilocks Zone." While Dremel recommends 190-220°C, the ideal setting depends on your specific printer hot end, print speed, and desired finish.

- action: Start with the Dremel’s mid-range (~205°C). Print a temperature tower calibration model to visually identify optimal settings. Looking for:

- Minimal guy wires between towers.

- Smooth, shiny surface finish – not matte or speckled.

- Good bridging and drape properties.

- No curling at the sharp corners.

- action: Start with the Dremel’s mid-range (~205°C). Print a temperature tower calibration model to visually identify optimal settings. Looking for:

-

Key Hugs of Beds: Adhesion and Flatness

Even the best filament can be ruined by a failed first layer of bonding. PLA prefers a clean, slightly tacky surface.

- action: Use a feeler gauge to ensure the bed is flat. Use a clean printing surface:

- Glass/Emery: Wipe gently with isopropyl alcohol (IPA). Hairspray or a diluted PVA glue stick adds reliable stickiness to the intricate first layer.

- Prince Edward Island: Clean with IPA. If worn, light sanding with fine sandpaper can restore bonding properties.

- Bed temperature: 60°C is generally the optimal temperature for Dremel PLA—hot enough to bond and cold enough to prevent legging. Large prints initially benefit from around 70°C, dropping to 60°C after layer 5.

- action: Use a feeler gauge to ensure the bed is flat. Use a clean printing surface:

-

Cooling: Sharp Edges

PLA benefits from rapid cooling after extrusion, especially for bridges, overhangs and fine details. Insufficient cooling can result in droop, loss of detail, and potential layer shifting.

- action:

- Enable and maximize your part cooling fan speed (usually 100% starting at level 2 or 3).

- Orient the part to maximize surface exposure to cooling airflow.

- Avoid printing large, solid parts too quickly—they retain heat.

- action:

-

Speed and flow: finding harmony

Printing too fast will prevent a layer from blending properly with the previous layer and put stress on the extruder motor. Too slow can cause nozzle drag and overheating.

- action: Start with the Dremel’s recommended speed (usually 40-60 mm/sec). For complex models that require detail resolution, reduce speed (especially perimeter). Calibrate the E-step (number of extruder steps per millimeter) and adjust the flow rate (extrusion multiple) using a single-wall calibration cube to ensure dimensional accuracy and correct extrusion width.

- postprocessing elevation

While the original results of PLA prints look great, the professional finish needs improvement – GreatLight takes prototyping excellence even further in this area.

- Basic knowledge: Sanded (starting with coarse sanding to remove lines and progressing to ultra-fine grit), polished with compound/micro mesh, painted with PLA special primer/paint.

- Advanced technology: Our one-stop post-processing services utilize steam smoothing, sandblasting to achieve a uniform matte texture, professional paint finishing, assembly, CNC machining integration and coatings to enhance durability or aesthetics where appropriate. Don’t waste DIY time; utilize expert finishing techniques to produce ready-to-go parts.

Troubleshooting Quick Guide

- Brushing/bleeding: Increase retraction distance/speed (starting: 4-6mm @ 35-45mm/s). Reduce the nozzle temperature slightly. Enabling /z-hop with caution.

- Warp/warp angle: Make sure the bed surface is clean and the bed temperature is correct. For small footprints or drafts, use a brim. Enable windshield.

- Poor adhesion between layers: Increase the nozzle temperature slightly. Ensure extrusion consistency (clean nozzle/no clogging). For larger parts, reduce the cooling fan speed slightly.

- Spots/acne: Minimize print pause points – adjust retract/glide settings. Ensure consistent squeezing.

Conclusion: From prototype to perfection

Master Dremel PLA filament to take your FDM printing from "OK" To excellence. By controlling humidity, carefully calibrating temperature and speed, ensuring bed adhesion, optimizing cooling, and using strategic post-processing, you can achieve reliable, high-quality results. These principles reflect our commitment at GreatLight: leveraging advanced SLM 3D printers and rigorous process controls to deliver unparalleled precision metal prototypes and production parts. We bridge the gap between digital design and tangible reality.

Whether your project requires complex geometries in PLA as concept models or mission-critical metal parts that require SLM accuracy and robustness, expert materials handling and process optimization are the foundation. Ready to take your next project beyond standard printing? GreatLight specializes in transforming complex visions into flawlessly executed realities.

Customize your precision rapid prototyping parts today! (Hyperlink assumed to be to GreatLight’s quote/services page)

Frequently Asked Questions (FAQ)

Q1: Is Dremel PLA really better than ordinary PLA brands?

A1: Compared to budget filament, Dremel PLA offers tighter diameter tolerances and consistent formulation, significantly reducing extrusion inconsistencies and potential clogging. While general-purpose PLA works just fine, Dremel embodies repeatable quality, which is especially important for reliable prototyping and functional testing where dimensional accuracy is critical.

Question 2: How important is printer calibration?

A2: Absolutely important. Even high-quality filament relies on carefully tuned machines. A level bed, calibrated E-step, clean hot end, and tested temperature tower form the non-negotiable foundation for any PLA success, especially when pushing the limits of detail or intensity. At GreatLight, machine calibration is continuous – a necessity for industrial-grade output.

Q3: Can Dremel PLA be used outdoors?

A3: Standard PLA has limited UV and thermal stability and will become brittle/deformed if left outdoors for a long time. While Dremel offers formulations with improved weatherability (such as PLA Pro/PHA blends), true outdoor durability requires engineered thermoplastics (PETG, ASA) or the specialty metals/permanent coatings we apply in post-processing.

Q4: How is GreatLight different for complex prototyping?

A4: We go beyond FDM:

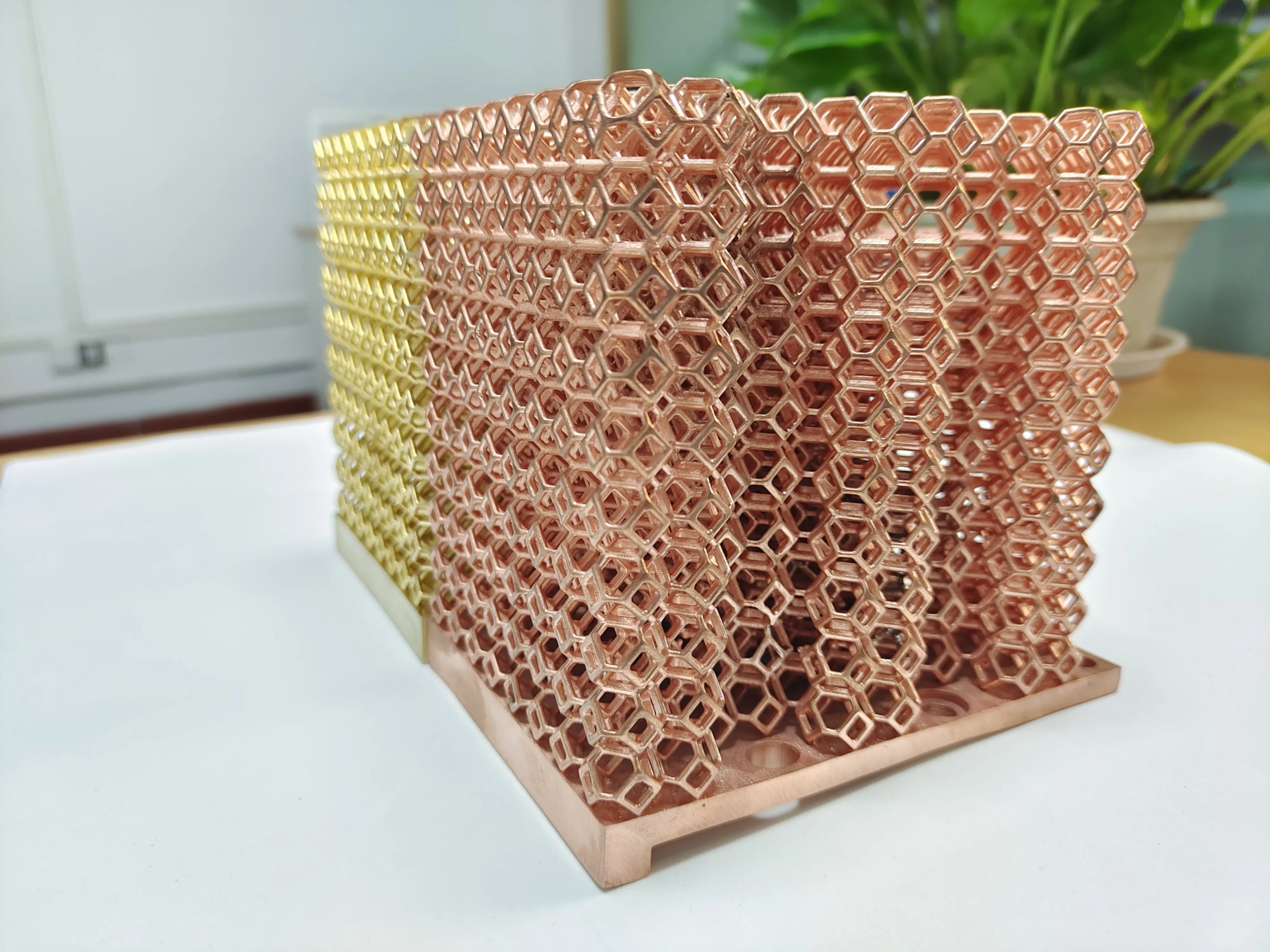

- Advanced technology: Industrial SLM 3D printers can handle complex, high-intensity geometries that FDM cannot handle.

- Materials expertise: Huge library (aluminum, titanium, stainless steel, custom alloys) + ability to provide optimal material recommendations for every application.

- End-to-end solution: Seamlessly integrate printing, CNC machining (for truly tight tolerances), comprehensive finishing (smoothing, plating, painting, assembly) and rigorous quality assurance – quickly producing production-ready parts.

- Speed and customization: Committed to quick turnaround without sacrificing precision and scalability for low to mid-volume production.

Q5: I have difficulty processing detailed PLA printing. Which steps in GreatLight’s post-processing are critical?

A5: Detailed information:

- Support removal: Expert hands-on work (plus dissolvable supports where feasible) can minimize damage.

- Cleaning/priming: Residues/marks removed and ready for finishing.

- Precision grinding: Graded abrasive grains refine surfaces without rounding edges.

- Filling/Putty: Resolve minor surface defects.

- Fine Painting/Micro Coating: Achieve color accuracy and a flawless appearance, often combined with textures such as sandblasting.

- Protective coating: UV-resistant varnish maintains the integrity of details.

GreatLight can handle these complexities, converting complex PLA output into design-accurate demonstration models or functional prototypes that meet strict appearance requirements.