Electroplating 3D printing: unlocking aesthetic and functional potential (includes conclusion and FAQ)

The magic of 3D printing is its ability to quickly and accurately transform digital designs into tangible objects. But what if we told you that the journey doesn’t end on the print bed? Ideal for parts that require enhanced durability, conductivity, wear resistance, or just a stunning metal finish electroplating gifts Invaluable post-processing solution. At GreatLight, we believe plating is not just a cosmetic upgrade, but a bridge between rapid prototyping and final use of metal parts.

Why plate 3D prints?

In addition to the charming reflective humiliation and stunning metallic luster, electroplating has significant advantages:

- Enhanced durability: Significant metal plating Increase Parts’ resistance to scratches, abrasions and physical impact.

- Improve weather and chemical resistance: Electroplating creates a barrier against oxidation (rust), UV degradation, and corrosive chemicals.

- Conductivity: Coatings such as copper, nickel or silver enable previously insulated plastic parts to efficiently carry electrical current.

- Heat dissipation: certain metals (copper) to improve heat dissipation from electronic enclosures or radiators.

- EMI/RFI shielding: Nickel/copper layers can effectively shield electromagnetic interference.

- Reduce permeability: Forms an effective gas and liquid barrier.

- Improved tribological properties: Significantly reduces the friction coefficient of moving parts and enhances wear resistance.

- Improve aesthetic value: Achieve unparalleled metal finishes – chrome, brass, gold, polished nickel – to elevate prototypes to demonstration-grade or final product quality.

The secret of electroplating process

Electroplating involves depositing a thin layer of metal onto a conductive surface (substrate) using an electrochemical process. Here is a simplified breakdown (Results will vary):

-

Surface treatment (key): This is arguably the most important stage, especially for plastics.

- clean: Use a specialized degreaser to remove oil, grease, fingerprints and printing residue.

- Etching: For plastics, especially ABS and ABS-like resins, chemical etching can roughen the microsurface and chemically modify it to improve adhesion. Common etchants include chromium-based or newer chromium-free alternatives.

- Sensitization and activation: Creates catalytic sites required for metal deposition.

- Electroless deposition: Chemically deposited base layer of nickel or copper (No electricity) onto the activated surface. This step makes the entire surface conductive.

- plating: The component (cathode) is immersed in an electrolyte containing a dissolved metal salt of the desired coating (e.g. nickel sulfamate, copper sulfate) and a direct current is applied using a power source.

- The metal ions in the solution are reduced at the cathode/component surface to form a continuous metal layer.

- The anode (usually made of electroplated metal) dissolves, replenishing the ions in the plating solution.

- Precise control of current density, bath temperature, pH, chemical composition and soaking time controls thickness and coating performance.

Popular coating options:

- copper: Excellent electrical conductivity, heat dissipation, and EMI shielding. Typically used as a base layer for bright nickel/chromium plating or RF applications. Understandable soft It is gentler when used alone.

- nickel: Highly versatile. Offers excellent corrosion resistance, durability, hardness and brightness. Can be bright or semi-bright and is often used under chrome plating.

- Chrome (decorative chrome): Known for its brilliant blue-white luster and excellent hardness/wear resistance.Practically always painted over bright nickel.

- Gold/Silver: Mainly for aesthetics, electronics (contact points) or corrosion resistance. Available directly plated or as nickel/copper overlay.

- Tin/Lead/Solder: Mainly used for solderability in electronic assemblies.

Key Considerations for Successful Plating

- 3D printing materials: Not all materials plate equally well.

- Outstanding candidates: ABS/ABS-like resin, polylactic acid PLA (using special process), polypropylene PP (using specific etchant), UV resin specially designed for electroplating.

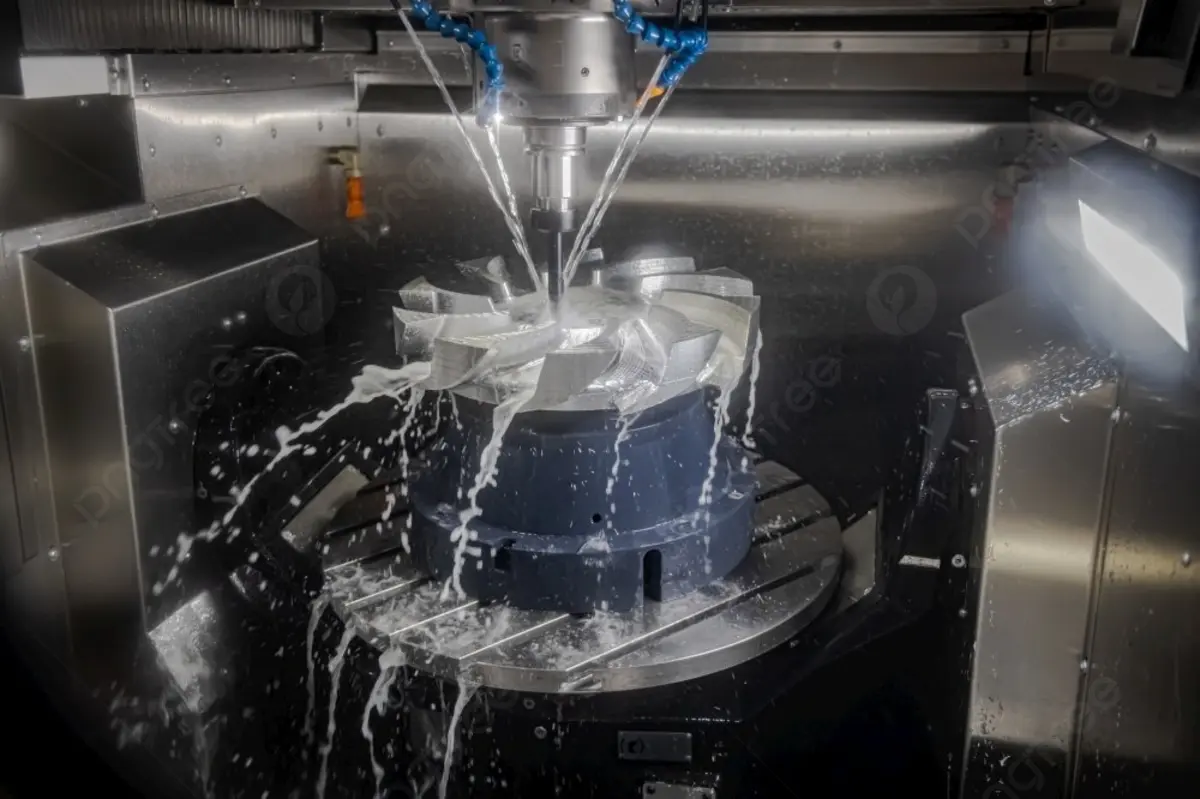

- Challenging/poor candidates: Polyamide (nylon) PA, polycarbonate PC, TPU/TPE (flexible resin), PVA/support material. Metalizable grades exist but require proven expertise. Metal 3D printed parts (SLM, DMLS) can also be plated for enhanced corrosion resistance or specific coatings, but require different preparation.

- direction: Avoid providing support on critical surfaces as cleaning/ventilation may result in staining or poor adhesion.

- Surface quality: Plating can amplify surface defects. Grinding/polishing before plating produces better results.

- Porosity: SLA resin can be porous; penetration/epoxy sealing may be required before plating. Lower line FDM printing poses major challenges No Solid sanding/filling treatment.

- geometry: Deep grooves and internal channels complicate cleaning, rinsing and achieving uniform coating thickness. Proper placement and stirring of the solution are critical. Stress concentration points like sharp corners may exhibit thicker build-up or uneven plating ("dog bones").

- ventilation: Trapped air inside hollow components can expand during chemical processes, causing defects. Drain/drill vents strategically.

- Chemical sensitivity: Make sure the substrate and any solvents/fillers used are compatible with corrosive plating chemicals.

- Professional execution: Successful electroplating requires expertise, precise process control, proprietary recipes and proper waste disposal (no Suitable for DIY! ). offshore power entrust Making sure your plating is done at a professional shop like GreatLight can minimize your risk.

Application: The shining point of electroplating

- Functional prototypes (connectors, housings, RF components) that require metal-like durability and conductivity.

- Cosmetic prototypes for demonstration, display models that reflect the final look.

- Creation of end-use components: wear parts, lightweight mechanisms, award-winning final inspection covers, knobs, enclosures with integrated EMI shielding.

- Car parts (interior/exterior simulation).

- Vintage/Collectible Replica Wanting Metal Finish.

- Architectural models/models requiring metal finishes.

- Master of electroforming for creating complex molds.

Conclusion: Linking prototypes to production

Electroplating transforms 3D printing from utilitarian models into complex assemblies that can serve functional needs or dazzling aesthetics. Although fraught with nuances, especially in terms of material suitability and pre-treatment, professional plating can unlock unparalleled capabilities. From enhancing the conductivity of complex PCB test fixtures to achieving a mirror finish worthy of prestigious and iconic awards, plating significantly extends the functional life and impact of rapid prototypes.

At GreatLight, our vertically integrated rapid prototyping solutions include expert printing (leveraging advanced metal SLM technology and multiple plastic processes) and comprehensive post-processing, including carefully developed electroplating technology. We leverage our in-depth knowledge of material compatibility and specialized plating process parameters to ensure your prototypes not only look great, but have enhanced performance, effectively accelerating your innovation cycle. Work with us to seamlessly integrate electroplating or any other finishing technology into your prototyping workflow, taking your ideas from concept to convincing reality.

FAQ: Plating 3D Printed Parts

-

ask: Украина Can I plate any 3D printing plastic? Continuous training

one: No, ABS and ABS-based blends/modified alloys are generally considered ideal for traditional electroplating processes (Chrome Chromic acid etching), improved smoother alternatives exist. PLA requires a specialized etching/activation process. Resins such as PA, PC, TPU/TPE, PEEK etc are very difficult/commercially unviable outside of specialized metallized grades. Metal prints (SLS/SLM) can also be plated. -

ask: How durable is the plastic plated continuous shower hot water temperature?

one: Proper plating on appropriate plastics with adequate pre-treatment can be very durable. However, impact resistance remains a limitation. Very sharp droplets/thin features coated with brittle chromium may shatter under significant deformation, exposing the underlying plastic substrate. The copper/nickel layer has a lower brittle residual thickness than the chromium layer. -

ask: Is electroplating good for metal 3D printed parts?

one: Absolutely. Electroplating dissimilar metals such as chromium/nickel can significantly enhance corrosion resistance (critical for reactive metals), improve wear resistance (can increase surface hardness), reduce the coefficient of interaction friction, or provide a sacrificial coating on softer base metals in harsh environments. -

ask: How thick is the plating applied?

one: Thickness gradually builds up depending on factors such as soaking time and intensity of amperage practiced diligently. Decorative/bright nickel coatings typically range from ~5-25µm (~0.0002" – 0.001"). Decorative chrome is very thin (~0.25 – 1.0µm / ~0.00001" – 0.00004"). Copper can be built efficiently; thicker layers (>20μm) often meet functional needs. Professional coatings can be measured to exacting specifications (< ASTM B368, etc.). -

ask: Will plating cover layer lines?

one: Electroplating strives to replicate the underlying surface finish streaks not just its mask. Although nickel plating is moderately resilient, severely visible layer lines may still become apparent later on. Better results require careful surface preparation beforehand: sanding with progressively finer grit, followed by polishing with a polishing compound, will give you the best results before plating begins. -

ask: How does UV resistance affect electroplated plastics?

one: Prolonged exposure to UV rays (direct sunlight Monthly outdoor exposure) may eventually subtly degrade the underlying polymer resin over a long period of time; the insulating plating metal shields it to a certain extent, but resin degradation itself is still unavoidable in the long term. The “chrome” finish on Nickel/Chrome Coupons is itself highly UV resistant. - ask: Can newer materials replace ABS for plating?

one: Emerging technologies continue to improve the feasibility of electroplating a variety of materials. Market-specific chemistries promote plateability of complex thermoplastics

(Word count: near maximum limit for detailed insights)