Unlocking Precision: A Comprehensive Guide to Elegoo MSLA 3D Printing

The world of 3D printing offers an incredible array of technologies, each with unique advantages. If high detail, smooth surface finishes and complex geometries are critical to your project, MSLA (Mask Stereolithography) Resin printing, especially from a popular brand like Elegoo, deserves your serious attention. MSLA goes beyond hobbyist FDM (Fused Deposition Modeling) to provide access to professional-grade results, making it invaluable for rapid prototyping, detailed modeling, jewelry, dental applications, and more. Let’s take a deeper look at the Elegoo MSLA ecosystem and how mastering it can revolutionize your production.

What is MSLA and why choose Elegoo?

MSLA explained: Unlike filament printers, which melt plastic, MSLA uses a liquid photopolymer resin that is cured by UV light. The core innovation lies in its light source. Instead of laser tracing paths (like traditional SLA), MSLA uses the LCD screen as a dynamic mask. This LCD screen selectively blocks UV rays from the array (usually LEDs) beneath it, projecting a single layer of images onto a vat of resin. Only the exposed areas are immediately cured and set to the build plate. The plate then rises, the LCD screen updates the mask for the next layer, and the process is repeated layer by layer, building the object from the bottom up. Parallel curing of the entire layer gives MSLA a significant speed advantage over laser-based SLA.

The Rise of Ellegu: Elegoo comes out and offers exceptional value. They offer powerful, user-friendly MSLA printers (like the Saturn and Mars series) with features commonly found on more expensive machines—high-resolution monochrome LCD screens, powerful UV light arrays, durable build components, and intuitive software—at very affordable prices. This popular, high-detail resin print makes it a favorite among hobbyists, professionals looking for an affordable solution, and businesses like ours for specific prototyping needs.

Dive Deeper: Key Components and Technologies of Elegoo MSLA Printers

- UV light source (LED array): Strong. Elegoo printers utilize powerful UV LEDs to emit light at a specific wavelength (usually 405 nm) optimized for common resins. Newer models have more powerful arrays and efficient cooling for faster cure times and longer service life.

- High-resolution monochrome LCD screen: This is the key differentiator. Early machines used RGB screens, which blocked more UV rays and degraded quickly. Monochrome LCD display, Now standard on newer Elegoo models:

- Transmits UV light more efficiently, resulting in faster print times (sometimes 2-4x faster than RGB screens).

- The service life is significantly longer (typically over 1000 hours compared to about 200 hours for RGB).

- Delivers superior edge sharpness due to higher resolution and better pixel contrast. Resolutions such as 4K (3840×2160) and even 8K are now common on larger format Elegoo machines such as the Saturn 3 series.

- Resin cylinder: Metal or molded plastic tanks hold liquid resin. It has a key Flexible FEP (fluorinated ethylene propylene) film at the bottom. This clear film allows UV light to pass through, but creates a non-stick surface from which the cured layer peels away after each exposure. Proper FEP tension is critical to successful printing.

- Build the board: Typically an aluminum platform that is lowered into the resin. A textured surface or strong adhesive system ensures the first layer adheres firmly during the printing process.

- Z-axis mechanism: A precision lead screw or twin-screw system that controls the vertical movement of the build plate. Accuracy here is critical for consistent layer heights.

- Electronic controls and firmware: The brain of the printer. Modern Elegoo models feature responsive touch screens and software that simplify setup, leveling and control. Features like anti-aliasing (smoothing pixel edges on curved surfaces) are increasingly common.

Elegoo MSLA workflow: from file to finished print

Success depends on following each step carefully:

-

Design and Slicing:

- Your journey starts with a 3D model (STL/OBJ). Key considerations for resin printing include: orienting the part to minimize support and suction, adding supports in invisible areas (flat surfaces facing downwards can create huge peel forces), and hollowing out the model with drainage holes to save resin (critical for large objects).

- Slicing software: This is where the real magic happens. You will use software like Chitubox (usually bundled or recommended by Elegoo), Lychee Slicer or UVTools. This software:

- Orient and position the model on the virtual build plate.

- Generate critical support structures.

- Cut your model into precise layers that your printer can understand.

- Allows setting core parameters: Floor height (e.g. 0.05mm, 0.03mm – lower = finer detail but slower), Exposure time (per layer and base layer – vital!), Elevator speed/height, rest time (After withdrawal).

- exit: Slicers output proprietary files (for example,

.ctb,.cbddlp) contains all instructions and image masks for LCD.

-

Printer settings:

- environment: Work in a well-ventilated area (resin fumes are toxic). Specialized housings, like Elegoo’s own range hoods, help contain smoke and stabilize temperatures (optimum 25-30°C / 77-86°F).

- Resin: Carefully pour the resin into the bucket to avoid creating air bubbles. If it has settled, stir gently. Know your resin type (standard, ABS-like, tough, flexible, washable, pourable) and its optimal settings – These vary greatly!

- Bed leveling: This is a non-negotiable step. Loosen the printing platform plate, place the leveling card (or folded paper) on the LCD screen, lower the platform until it firmly contacts the card, tighten the screws in the recommended order, and set Z=0. Ensures perfect first layer adhesion. Newer Elegoo models simplify this process.

-

print:

- Transfer slice files to printer (USB stick).

- Select the file and start printing.

- Monitor the first few layers: This is critical! Observe to ensure that the initial base layer adheres correctly to the build plate. Once you’ve successfully dropped the first few millimeters, the print will usually be stable (unless there’s an electrical or mechanical failure). Do not leave it unattended initially.

- Post-processing (non-negotiable final steps):

- Delete printing: When finished, carefully lift the build platform plate. Use a plastic scraper to gently pry open the finished print. Never use metal directly on the build plate! Be careful of dripping uncured resin.

- clean: Residual uncured resin is toxic and sticky.

- Solvent bath: Soak the print in isopropyl alcohol (IPA) depending on your resin type (usually 90%+ IPA). Ultrasonic cleaners greatly speed up this process. Use a two-stage cleanse (dirty IPA bath, then clean IPA rinse) for best results. commercial "Resin cleaning" Stations are common upgrades.

- Washable resin: Use water for easier cleanup (but make sure to dispose of it properly!).

- Remove supports: Carefully cut and peel off the supports. Tweezers and flat snips are a must. The remaining small pieces can be sanded. do this back Clean but forward Final solidification.

- Final cure: Only through additional UV irradiation can the resin fully cure and reach its final mechanical properties.

- Dedicated UV curing chamber/mercury lamp: Provides uniform, powerful UV light for efficient curing (a few minutes to tens of minutes).

- Sunlight: Works, but unstable, weather dependent, and slow (hours). Not ideal.

- Safety first! Wear nitrile gloves and safety glasses when handling uncured resin and IPA. Work in a well-ventilated area. Properly dispose of contaminated materials in accordance with local regulations.

Expert Tips: Vacuum degassing of resins (especially colored/dense resins) before pouring can significantly reduce microbubbles that compromise surface quality in demanding applications.

Why Elegoo MSLA is good at rapid prototyping (industrial perspective)

For a company like this huge lightContinuously meeting complex rapid prototyping challenges, Elegoo MSLA printers shine in specific scenarios:

- Unparalleled resolution and detail: Capture microscopic features, textures and crisp edges that FDM cannot capture. Critical for form, fit and fine feature verification. Think intricate mechanisms, beautiful engravings, life-like models, fit checks on connecting ports.

- Excellent surface finish: Prints with minimal layer lines – significantly reducing or eliminating the need for painting or sanding prior to mold preparation.

- Iteration speed: Compared to FDM prints of equivalent detail, print times are typically measured in hours rather than days. Faster design cycles = faster innovation.

- Multiple material options: Beyond standard resin:

- ABS-like hard resin: Provides superior impact resistance and durability for functional prototype testing.

- Tough/Durable Resin: Simulates engineering thermoplastics such as polypropylene (PP).

- Flexible/rubber-like resin: Ideal for seals, fixtures, ergonomic studies.

- High temperature resin: Used for thermal deformation testing.

- Castable resin: Burn clean for metal casting workflows (jewelry, dental).

- Ceramics and filled resins: Provides unique material properties.

- Cost-Effective Complexity: Unlike methods that require complex supports or multiple operations, building complex hollow geometries or lattice structures does not significantly increase printing time or cost.

At GreatLight, we leverage these strengths every day. MSLA is our top choice:

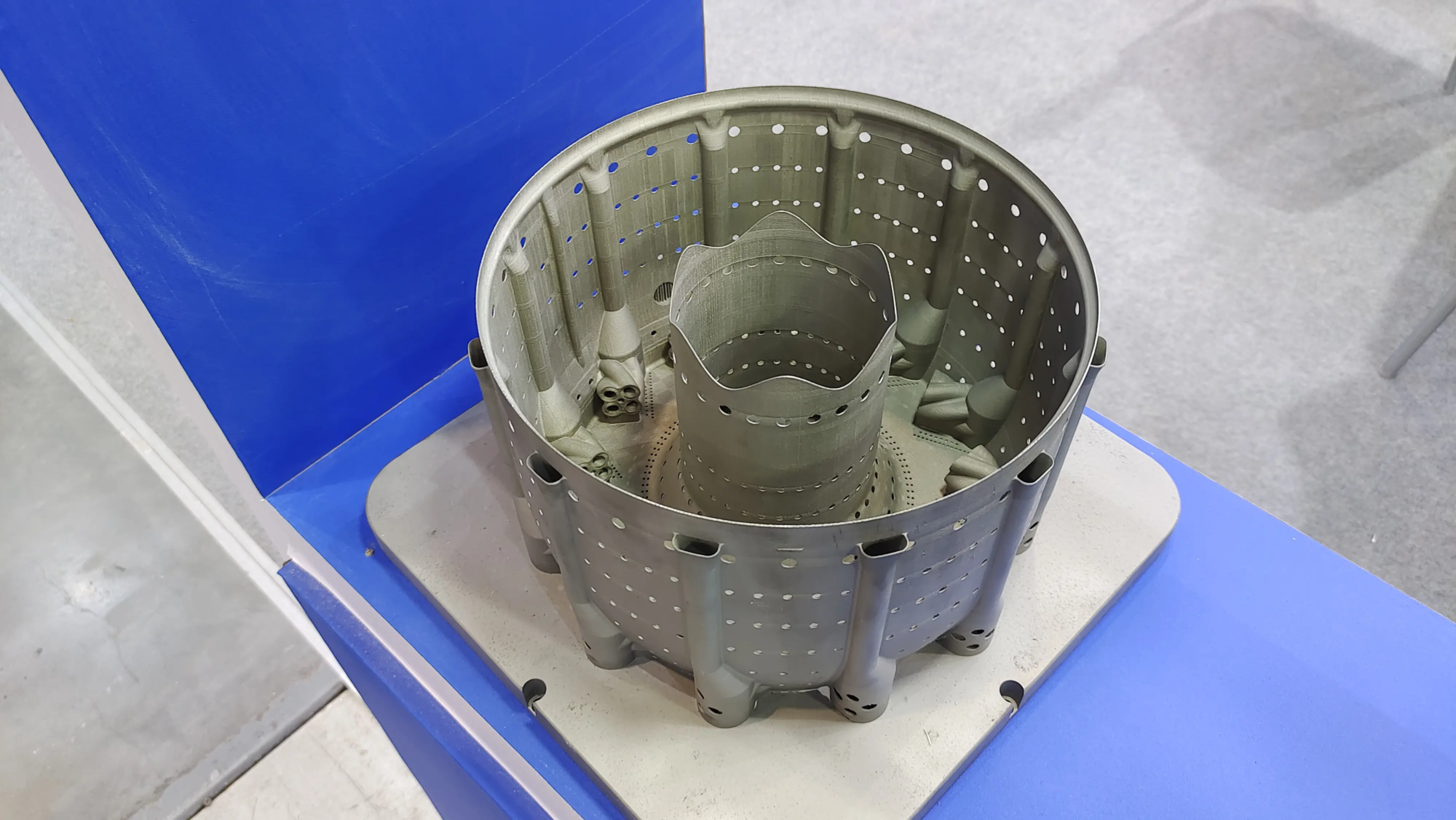

- Prototype complex electronic enclosures (pre-mold fit inspection).

- Figurines, detailed scale models and medical training aids.

- High-precision snap assembly verification is required.

- Lost wax casting patterns for precision metal parts.

- Clamps and fixtures requiring smooth surfaces.

However, key considerations remain:

- Material properties: Not all resins match the absolute strength/stiffness/temperature resistance of injection molded thermoplastics. Engineering resins bridge the gap, but require expertise.

- Isotropic: Compared to injection molding, resin prints can be slightly anisotropic (more in the XY plane than in the Z plane), and sometimes specific orientations need to be taken into account.

- Post-processing overhead: Cleaning and curing are mandatory, adding to labor/time/supply costs. Automation (washing/curing stations) can help.

- Size restrictions: Build volumes, although growing (Saturn series), are generally smaller than industrial FDM/SLS systems.

- Toxicity and Handling: Robust security protocols beyond standard FDM are required. Resin waste disposal must be handled responsibly.

Conclusion: The power of precision is within your reach

Elegoo MSLA 3D printing represents a technological leap forward in the accessibility and capability of high-detail, smooth surface additive manufacturing. By bridging the gap between professional-grade results and consumer affordability, Elegoo enables manufacturers, designers, engineers and businesses to create parts that were once prohibitively expensive or difficult.

Understanding the technology—the importance of monochrome LCD, resin chemistry, fine sectioning (supports, exposure), mandatory post-processing, and critical safety protocols—is fundamental to unlocking its full potential. While there are material limitations and process overhead considerations, the advantages in detail, surface finish, iteration speed and accessible cost are undeniable.

For partners like huge lightintegrating the powerful Elegoo MSLA printer into our arsenal of advanced rapid prototyping tools provides indispensable flexibility. It allows us to quickly produce high-precision, detailed prototypes for visual evaluation, functional testing using specialized resins, and even cast models, ultimately accelerating our customers’ journey from concept to market-ready product. Whether you’re a hobbyist making miniatures or an engineer prototyping complex components, mastering Elegoo MSLA opens up a world of possibilities where precision meets practicality.

FAQ: Your Elegoo MSLA questions answered

-

Q: Is the Elegoo MSLA printer easy to use?

- one: Setup and leveling require care, but the core printing process itself is usually simpler than FDM adjustment. The main challenges are learning post-processing, safety, and mastering microtome settings for different resins. After correct settings, press "Print" Very simple.

-

Q: What is the service life of the Elegoo LCD screen?

- one: The monochrome LCD screens used in newer Elegoo models (Saturn/Mars 3/4, etc.) typically last between 1,000 – 2,000 hours of printing, significantly longer than the ~200 hours of older RGB LCD models. Screen life will decrease faster if the UV power setting is higher and the exposure time is longer. Keep your screen protector clean!

-

Q: What safety equipment is required for resin printing?

- Answer: Non-negotiable: Nitrile gloves, safety glasses. Highly recommended: Respirator with VOC/organic vapor filter (especially in poorly ventilated areas), dedicated lab coat/apron. Good ventilation is crucial.

-

Q: Can I use any resin in an Elegoo printer?

- one: Technically, most 405nm UV resins will work. but, Critical! you must Dramatically adjust microtome settings (exposure time, lift speed) for different resin types (standard, ABS-like, tough, flexible) or even different colors/brands within the same type. Always follow the manufacturer’s recommended settings as a starting point and for calibration.

-

Q: Why are supports needed and are they difficult to remove?

- one: Supports secure the print to the build platform and provide stability during the print process, especially for overhangs (usually >45° angles) and islands. They are essential. Care is required when removing – carefully snip or peel after cleaning but before final curing. Success depends on correct support settings in the microtome (tip contact point, density) and using the correct tools.

-

Q: How to dispose of resin waste?

- Answer: Uncured resin, cleaning solvent (IPA), cleaning rags, filters, etc. are all hazardous waste. Do not pour down drains or throw into regular trash. Completely cures all resin waste (Place in UV/sunlight) until hardened, then follow local hazardous waste disposal regulations. Recycle IPA whenever possible.

-

Q: Are MSLA prints robust enough for functional parts?

- Answer: Yes, but there are caveats. Standard resin is brittle. Use specialized "Similar to ABS," "tough," or "Durable" A resin with significantly better impact resistance and toughness (road cold fracture resistance, etc.) properties, approaching that of some engineering thermoplastics. Positioning and design optimization also play an important role in strength. They still generally cannot match the durability of engineering thermoplastics designed for high load-bearing applications.

-

Q: My prints stick to the FEP, not the print tray! Why?

- one: This is very common ("FEP failure"). Causes include: Improper bed leveling (too high), underexposed base layer, improper build plate texture/scraping/cleaning, lift speed too fast, FEP tension too loose (or too tight), temperature too cold.

-

Q: Do I really need a wash and cure station?

- one: Although not strictly mandatory, they are Highly recommended to upgrade. Cleaning with a specialized agitator (ultrasonic or electric) is faster, more thorough, and safer than manual cleaning. Dedicated UV curing stations provide uniform, efficient cure that is significantly faster than sunlight. Both are worthwhile investments for anyone who prints frequently.

- Q: How does Elegoo MSLA compare to the industrial SLA/SLS used by GreatLight?

- one: Elegoo MSLA offers great Detail and surface finishclose to industrial SLA. Key differences from high-end industrial machines (SLA/SLS) include: typically smaller build volumes, less selection of specialized (e.g., certified biocompatible, extreme temperature) resins, potentially slower for very large high-density parts compared to SLS, and less integrated material handling/recycling systems. However, for the cost, it offers excellent features. GreatLight leverages complementary technologies to meet the broader material, scale and certification requirements inherent in complex commercial/industrial rapid prototyping and metal part production.