Building Unparalleled Realism: How 3D Printing Changes the Structure of HO Scale

For decades, HO scale modeling has attracted its complex details and the ability to reproduce the micro world. Structures – buildings, bridges and industrial complexes – are the soul of convincing layout. Traditionally, making these with realism means hours of hard work with styrene, wood and gypsum. But a revolution is underway: 3D printing The possibility of HO scales is being redefined to unlock unprecedented details, customization and consistency at unimaginable speeds.

Beyond the Kit Carnival: The Power of Digital Manufacturing

Although traditional kit construction and scratch buildings are charming, they face inherent challenges. Implementing complex architectural details such as ornate brickwork, delicate cornices or intricate mechanical shells requires advanced skills and tremendous patience. It is very difficult to perfectly reduce the real world design. Does Volkswagen produce the same structure for urban scenes? tedious. In addition to 3D printing to remove these restrictions:

- Unparalleled details: High resolution printing can capture details by hand: individual bricks with texture, weathered wood grain, realistic roof tiles, fine pipes and exquisite window frames.

- Free design: Imagine modeling a specific building in your hometown, a unique factory of prototypes, or a completely original design. 3D CAD software transforms your vision into a printable digital model.

- Perfect repetition: Need the same warehouse or row of houses? They can be printed perfectly every time.

- Complexity: The internal structure, undercut and interlocking parts are fragile or impossible with traditional methods.

- Material versatility: Choosing the right material is key. ABS-like resins or engineered photopolymers provide rigidity and detail to static structures, while flexible resins can simulate tarpaulins or softer materials. Nylon PA12 is perfect for powerful industrial models.

From virtual blueprints to micro reality: a journey of 3D printing HO structures

- Digital Engraving: It starts with 3D models using CAD software (e.g., professional hobby tools like Fusion 360, Sketchup, Tinkercad, etc.). This is where the reference photos shine, ensuring scale accuracy and prototype fidelity.

- Slice and prepare: A special slicing software converts a 3D model into a thin layer (slice) to generate the printer’s instructions (G code). Orientation and support are key considerations in ensuring successful printing and minimizing cleaning efforts.

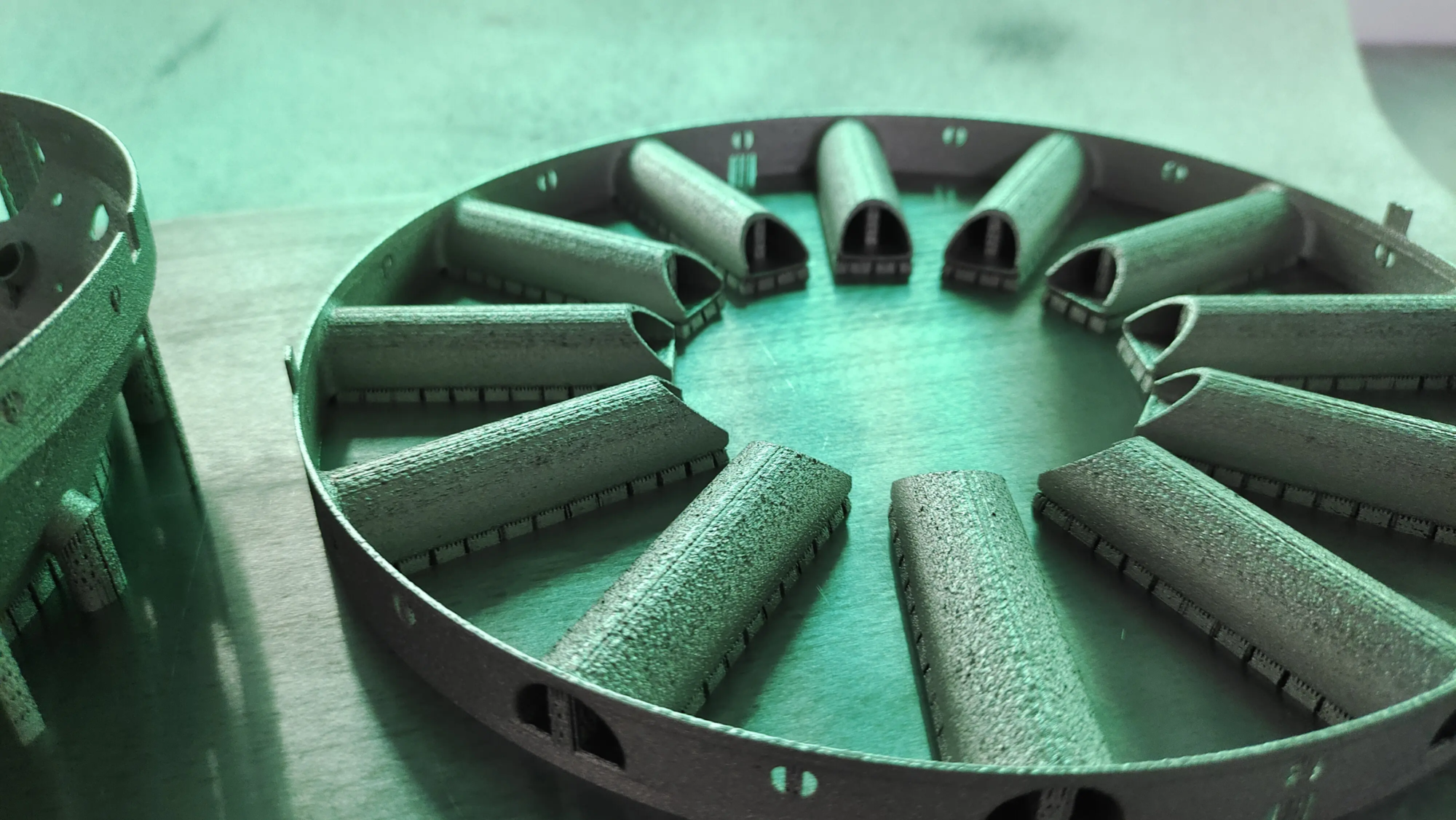

- Print: Modern Stereo-Lithography (SLA) and Material jetting (MJF) The technology is particularly suitable for HO structure. SLA uses lasers to heal liquid resins for amazing surface quality. MJF uses fine powders fused with liquid bonding agent and heat to provide excellent detail and strength while eliminating support during printing.

- Post-processing: Original printing needs improvement. Resin printing requires washing and UV curing. Carefully remove the support structure. This step is critical for the ultimate appearance and durability.

- Art Art: This is where realism really blossoms:

- start up: Create a uniform surface for paint adhesion.

- painting: Layering technology, washing and dry brushing brings depth and weathering.

- detail: The addition of light-etched brass, microstrip styrene, scenic elements (leaf, fragments) and glass really bring the structure to life.

Why Professional Manufacturing Is Important: Overcoming the 3D Printing Barriers at Home

While desktop printers are popular, HO meters require excellent accuracy. Consistently achieved on top-level layouts, high-quality results often push the limits of amateur FDM (Filament) printers and some resin machines. Challenges include:

- XY resolution and layer lines: Visible layer lines may destroy the illusion of brickwork or partition siding.

- Loss of details: Quality features such as window trim or mini bolts may not be presented well without professional grade equipment.

- Dimensional stability: Warpage and material inconsistency affect fit and completion.

- Material properties: Amateur resins/plastics may be fragile or degrade quickly.

This is where to work with professional rapid prototyping service providers Great Become a game rule.

Improve modeling through expertise

Great Utilize industrial grade SLM (Selective Laser Melting) For metal parts (excellent for robust, detailed industrial machinery) and high resolution polyjet and SLA Technology of plastic/resin structure. We specialize in transforming complex digital designs into body perfection, skillfully handling the unique needs of microscale modeling. Our capabilities go far beyond printing:

- Advanced Printer: Industrial machines conquer resolution barriers, provide smooth surfaces and capture details that are essential to the HO structure.

- Materials Science Expertise: Access to a wide range of engineering grade resins, nylons (such as PA12) and metals enables us to select the best materials for your structural function, durability and the desired final look.

- Integration post-processing: Our One-stop organization service Make sure to carefully clean, solidify, support structures according to your specifications. We handle resin removal and smoothing, allowing you to focus on painting and deployment.

- Prototype Excellence: Repeat iteration? Complex geometric shapes? Tight tolerances for modular systems? Our core capabilities in rapid prototyping ensure that we solve these problems effectively.

- Speed and customization: need "Unique" Quickly? We combine technical capabilities with fast custom processing to complete deadlines without sacrificing quality.

Time investment beyond the limitations of a universal suite or scratch the building. Professional 3D printing provides unparalleled freedom and loyalty.

Conclusion: The future will be printed in detail

3D printing is not just a tool for HO scale modeling; it is a paradigm shift. It enables modelers to achieve a level of realism and custom details, previously reserved for museum displays or master craftsmen with years of experience. By embracing this technology, especially using the accuracy and capabilities provided by professional partners Greatyou can fill in the layout with a truly unique, compelling structure that tells convincing stories. The only limitation is your imagination. Embrace the Future – Design, print and build realism.

Frequently Asked Questions about 3D Printing HO Structure (FAQ)

Question 1: Can 3D printed HO structures reach the same level of detail as high-end resin kits?

one: Absolutely and often surpass them. Professional SLA (high resolution resin printer) and material jetting can be finer details than many traditional casting processes (think individual brick textures or small rivets). The key is to use a high resolution printer with the appropriate resin or material.

Q2: Which file format do I need to use to model the 3D printed structure?

one: Solid, closed models are crucial. The industry standard format is STL (Stereoscopic Lithography) or updated, more information-rich 3mf. Make sure your design is varied (watertight) and includes the appropriate wall thickness for the materials and scales. Software like Netfabb or Magics can help check and repair files.

Q3: How durable is a 3D printed HO scale building?

one: Durability depends largely on the material:

- Resin (e.g., similar to ABS, engineering resin): Provides excellent detail and modest durability for static display layouts. Impact resistance varies.

- Nylon (PA11, PA12): It’s obviously harder, more flexible and resilient. Ideal for structures that may be frequently handled or require long-term elasticity.

- SLM metal (e.g., aluminum, steel): Very powerful and perfect for exquisite load-bearing parts such as highly detailed bridges, cranes or industrial machinery. Gremight excels in this regard.

Question 4: I am a modeler, not a CAD designer. How to print structure?

one: You have a choice!

- Licenses are available for design: Many talented designers sell printable STL files on platforms such as Cults3D, Thangs, or hobby-specific websites. Purchase documents and print them professionally.

- Commission custom design: Find freelancer CAD artists who specialize in scale modeling to create your unique architectural designs.

- Turnkey service (provided by Greatlight): Provide sketches, photos or references. Greglight can work with you through concepts, CAD design (or improvement), professional printing and finishing, a truly one-stop solution for achieving a specific horizon. Visit our contact page for consultation.

Q5: Why choose a professional service like Greatlight instead of my home printer for complex HO structures?

one: While desktop printers can be used for simple parts, museum quality results are achieved on complex HO structures, always requiring industrial-grade technology:

- Excellent resolution and finish: Industrial SLA, PolyJet and MJF machines greatly minimize layer lines and capture the micro-invisible of FDM/desktop resin.

- Material properties: Using high temperature resins, engineered nylon (PA12) or metals ensure unrivalled durability and life.

- Advanced post-processing: Professionally supported removal, cleaning and finishing brings unparalleled results.

- Proportional expertise: Understand the specific challenges of HO scale details and tolerances.

- Integration capabilities: Ensure that parts fit accurately, especially for complex components.

Question 6: What post-processing options are provided specifically for HO structures?

one: Our comprehensive services include:

- Expert support for deletion: Clean critical surface removal without damage.

- Grinding/smoothing: Minimize layer lines, especially for key vertical surfaces.

- Cleaning and curing: Ensure that the resin parts are completely inert and stable before completion.

- Start/paint preparation: Provides a model for preparing detailed information on paintings.

- Advanced effects: The potential for texture or specific finishes as required – query options.

Unlock the potential of HO layout. Explore professional 3D printing of structures that stand out with unparalleled realism and uniqueness.