Calling Life to the King of Darkness: The intricate art of 3D printing Darth Vader helmet

Darth Vader’s ambitious appearance is engraved in cultural consciousness, and nothing symbolizes his sinister existence as much as his iconic helmet. For role players, prop makers, and Star Wars enthusiasts, having or creating a Vader helmet with a screen accurate is a pinnacle achievement. Despite the traditional hand-made approach, 3D printing has revolutionized the task, making amazing entertainment easier than ever before. But did that iconic Dark King perfection be achieved? This is where real artistic, sometimes industrial-grade technology is.

From pixels to polymer: starting point

This journey is very far from the Milky Way, a long time ago: there is a digital design file. Finding high-quality, accurate STL files is crucial. Numerous talented creators offer models online, ranging from stylized interpretations to carefully scaled replicas based on screened props or archival references. Consider the following factors:

- accuracy: Does it capture subtle curves, dome details, ventilation holes, neck rings and complex grille geometry?

- Printability: Is it designed for ease of printing? Look for well-supported features and choose to split the model into assembly-friendly parts.

- Expected uses: Is it for static display, role-playing or functional electronics integration? This affects material selection and internal structure.

Desktop Hero: FDM Printing

For many amateurs, Fusion Deposition Modeling (FDM) is the portal to Vader Helmet Creation. Use filaments (PLA, PETG, ABS or ASA are popular choices):

- Challenges of scale: Printing a full-size helmet requires a large build volume. Printers like the Creality CR-10 series, Ender 5 Plus or larger industrial models are common choices. Helmets are usually printed in multiple parts (dome, panel, back, mouth/chim, ear cover, etc.).

- Key factors: Layer adhesion is crucial to structural integrity. Warp, especially on the large dome section, is a notorious enemy, proof of the manufacturer’s space that has been littered by countless failed prints. Heated bed, enclosed chamber (for ABS/ASA), meticulously flat and optimized cooling settings are not commercially acceptable for successful large prints. It is expected that the printing time will be encountered for several days, not hours.

- advantage: Relatively affordable equipment and materials, a wide range of material choices (including specialty finishes of silk or metal), and when printed well, the final part is strong.

- shortcoming: The visible layer lines require a lot of post-processing, most of which are risky of distortion, and may be weak at the layer joints during assembly, and a longer printing time.

Detail champion: SLA/DLP/LCD resin printing

For unparalleled surface details, resin printing (stereoscopic lithography – SLA, digital light processing – DLP or LCD) shines. This is ideal for capturing the intricate textures, precise grilles and fine mechanical details on the Vader dome.

- Departmental Methods: Because of the small amount of build on the consumer machine, it is often necessary to print the helmet in many small sections. Careful planning of cutting lines and orientation is essential to minimize visible seams and support marks.

- Details and power: Resin produces a surprisingly smooth surface directly from the printer, greatly reducing the post-processing time of cosmetic finishes. However, the standard resin can be brittle. For wearable helmets, choosing a durable or abs-like resin is essential to prevent cracking during treatment or wear. Curing is mandatory.

- advantage: Excellent detail capture, smoother surfaces significantly accelerate grinding/finishing, and have less-appreciation layers of high-resolution printers.

- shortcoming: Usually more expensive than FDM, resin needs to be messy, requires safe handling (gloves, ventilation), more brittle parts, and smaller build boards require complex segmentation and assembly.

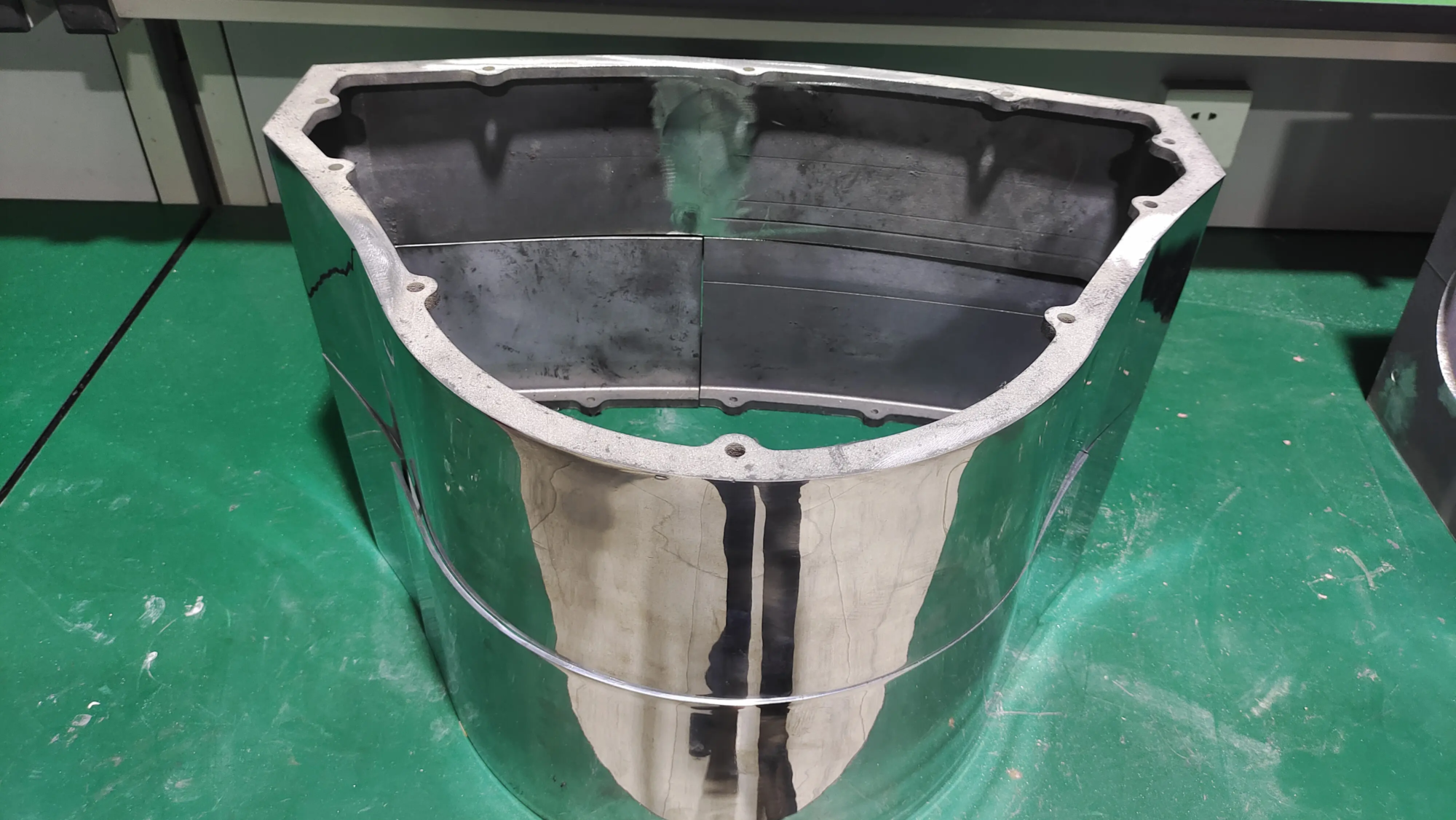

Conquer the Behemoth: When desktops aren’t enough – Industrial Solutions

Creating a truly seamless, durable and even functional Vader helmet (combined voice changer, breathing sound, LED lighting, cooling system) often exceeds the actual limits of desktop printing. This is Large format additive manufacturing (LFAM) and industry Selective laser melting (SLM) Metal printing services, just like the services provided Greatbecome the rule of the game. What problems did they solve?

- Seamless whole: The LFAM system has a larger building room. Imagine printing the entire helmet dome, panel and back Important, solid slices – Greatly minimizes seams and weaknesses, enhances structural integrity, and creates a more authentic unified feeling. This is crucial for high-end display pieces or demanding professional role-playing, where lines ruin the hallucination.

- Elasticity of industrial strength: The pressure that Darth Vader’s helmet wears wearable with cheap plastic can’t cope with. Industrial grade materials such as Paek (polyether), ULTEM™ (PEI) and robust nylon significantly improve durability, thermal resistance and impact strength compared to standard FDM/resin. They survived amid routines like Beskar, travel and unexpected bumps.

- Metal Fusion: Why settle for plastic? Selective laser melting (SLM) Allows the creation of metal helmets Element or functional internal structure. Imagine the authentic metal grille flashing LED lights behind it, custom metal brackets for internal electronics or cooling fans, or even a full custom metal interior frame that provides unparalleled rigidity. Greglight’s advanced SLM technology Allows to create these complex geometric shapes in metals such as aluminum, titanium and even stainless steel. Features comply with advanced techniques.

- Simplify complexity: Greatlight specializes in one-stop rapid prototyping partners. In addition to printing large or complex work, we deal with complex dances Post-processing: Precisely machining key interfaces (such as speaker mounts or neck ring connections), for perfect advanced smoothing technology, painting with automotive-grade finishes, chrome plating (for those real Tusken Sandpeople flashbacks!), integration of assembly and functional elements. Leverage Customized finishing service For masterpieces that can be truly displayed.

- Speed and scalability: Need a helmet craft or Sith Lord Squadron? Gremight combines rapid prototyping expertise with potential production expansioneven for complex projects, timely delivery and consistent quality can be ensured.

Victory Surface: Post-treatment is the Key

Regardless of printing method

- assembly: Adding FDM parts or resin parts requires precision. Methods include solvent welding (ABS/ASA), epoxy resin, mechanical bonding to pins/fasteners or late adhesives. Consistency is crucial.

- smooth: FDM printing requires a lot of sanding (through sand grains), filling the primer application and layered lines of point putty. Resin prints still require cleaning support marks and some subtle polishing. LFAM/industrial parts usually start to be smoother, but the original paint adhesion may need to be completed. Techniques such as vapor smoothing (for specific industrial plastics) can greatly reduce labor.

- Start and Painting: High construction filler primers are crucial. The layers are carefully polished until completely smooth. The black primer forms the foundation. Then there is the iconic finish: a deep black black achieved through highlighted automotive paint. The mouth/chin grille requires careful masking and painting.

- detail: Beautiful details such as silver (or metallic gray) "ivory" On the cheeks, the dome texture (usually achieved with PEI film in resin or careful paint technology), control panel lights (using LEDs), and mesh or perforated metal behind the grille.

Conclusion: From passion projects to industrial masterpieces

3D printing has unlocked the ability of fans and professionals to recreate one of the most legendary costumes in cinemas with unprecedented accuracy and customization. Although desktop printers empower specialized amateurs, realizing the ability to truly professional, durable, seamlessly integrated or functionally enhanced Vader helmets often requires the ability to manufacture advanced industrial additives.

This is Great. With the latest SLM Metal Printing For functional components, Large additive manufacturing For seamless polymer structures, Deep material expertise Durability and comprehensiveness One-stop organization service,,,,, Gremight solves complex rapid prototyping challenges Inherent in such an ambitious project. Whether you are pushing the boundaries of role-playing, creating display art or developing functional props, working with professional rapid prototyping services will improve your horizons, from prototypes to Sith Lord Perfection. Customize precision Vader helmet assembly with Greatlight – The power of the dark side is in line with industrial creativity.

FAQ: 3D Print Darth Vader’s Helmet

-

Can Greatlight print a full wearable Vader helmet?

- Absolutely. use Large format additive manufacturing (LFAM)We can print the main helmet sections (such as dome, panel, back) on desktop printers, which are much larger, seamless components than those on desktop printers. This minimizes the weaknesses of many glued joints, greatly improving the strength and integrity of wearable capabilities.

-

My Vader helmet is designed with a complex internal structure for electronics/cooling. Can you handle it?

- Yes, our expertise lies in Complex geometric shapes and functional prototypes. Whether it’s designing and printing custom internal channels for integrated cooling systems, voice changer/speaker stands, fans and batteries mounts, or mimicking the original intricate ventilation paths, SLM Metal Printing Advanced polymer AM technology enables us to create components that seamlessly combine form and function.

-

My model has been twisting during printing on my FDM printer. Can this be prevented?

- In uncontrolled environments, warping of FDM on large curved components such as helmet domes is very common. Our Industrial systems have precisely controlled, heated build chambers, advanced adhesion systems and optimized process parameters Designed specifically to reduce warping and residual pressure on large-scale prints.

-

How durable is the prototype helmet on the Greatlight compared to my home printer?

- Significantly more durable. When using consumer PLA or ABS on the desktop, we use Engineering industrial polymers (e.g. Paek, Ultem™, high strength nylon) and Metals through SLM. These provide excellent tensile strength, impact resistance, thermal stability and long-term creep resistance, which are critical for handling, repeated penetration or extreme environments such as stage lamps.

-

Can you print my helmet with metal?

- Yes, selective laser melting (SLM) is used. one Full The metal helmet will be too heavy. However, SLM is very suitable for production Key functional components: Truely detailed metal grille, internal structural support, cooling ducts, custom brackets, hinges, and even Dusken-style glasses lenses. It is perfect for high clothing areas or complex functional elements.

-

Do you provide post-processing/complete services?

- Yes, we offer a comprehensive one-stop service. This includes precise cleaning, support removal, machining interface, comprehensive smoothing/finishing for perfect paint preparation, custom paint (car gloss black, metal details, weathering), chrome plating, assembly and electronics (if needed). This provides professional, display or cosplay ready masterpieces.

-

I have my own high-quality STL files. Can Greatlight print it?

- Absolutely! We are experts in handling complex custom STL files. Our engineers will review your designs to understand any optimizations for large or functional printing and determine the best technology, materials and orientation before production.

-

How is the cost compared to printing at home?

- While the up-front machine for desktop printing is low, helmets that achieve high quality, durable, seamless, professional helmets involve huge material costs (especially for failure), huge labor time (printing, post-processing), and require professional skills. Greatlight provides efficiency and guaranteed quality. You need to pay for professional-grade materials, industrial machinery time, eliminating risks such as distortion, expert technical processing and time-saving finishing, resulting in superior products with faster overall turnaround.

-

Can Greatlight help smaller batches or production runs?

- Yes. While ideal for complex single prototypes, our capabilities extend to Effective small batch production. With fast tooling techniques or optimized LFAM/SLM processes, we can produce multiple high-quality helmets and provide consistent results for prop houses, clothing departments or special events.

- How to start my custom Vader helmet project with Greatlime?

- Contact us directly! Provides your project goals, design (if any), intended use (display, role play), required materials/finishes, and any functional requirements (electronics, cooling). Our team will analyze your needs and provide detailed quotes and recommended manufacturing strategies to bring your vision of the Dark King’s legacy to life.