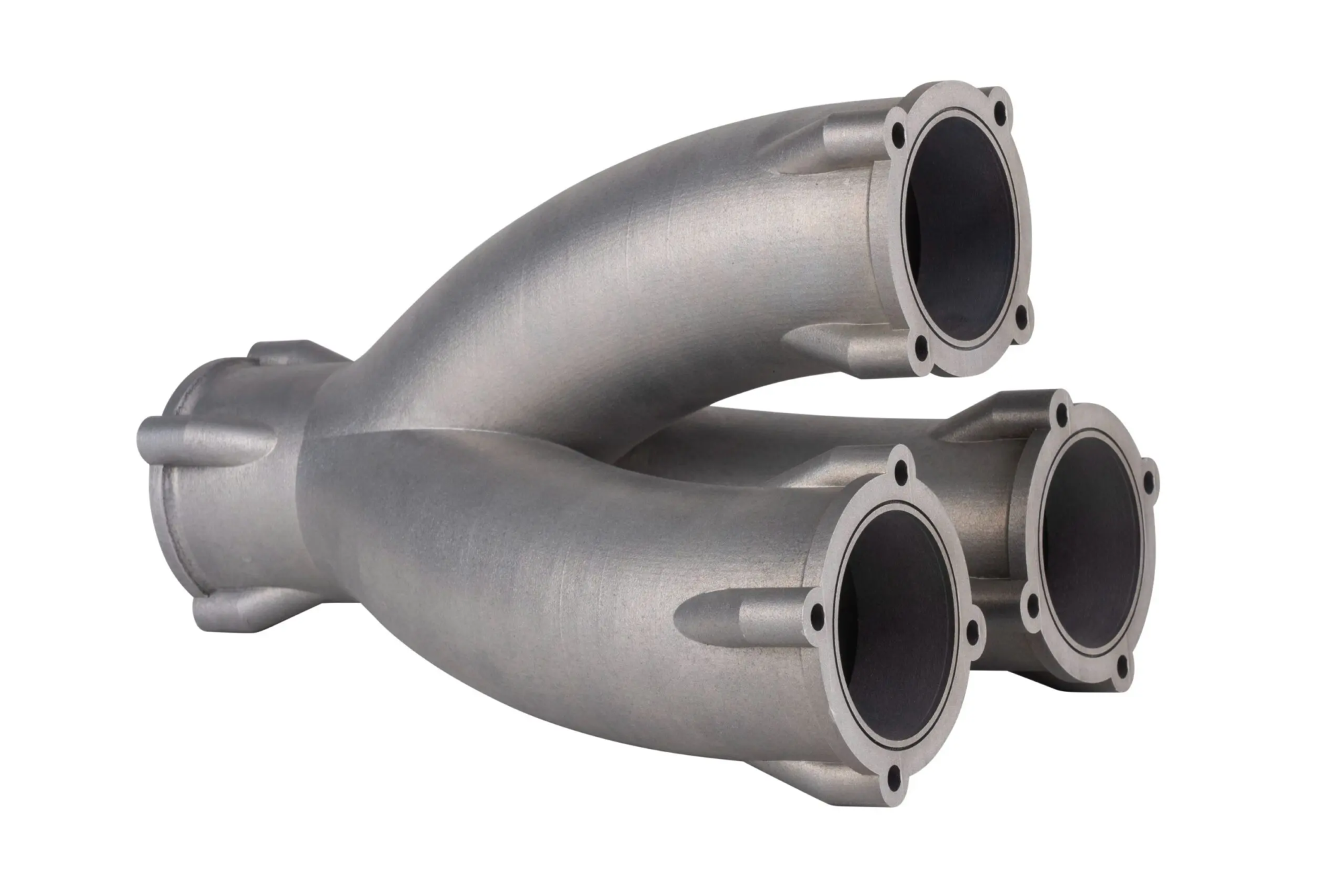

On October 20, 2024, according to the resource library, Ferrari recently launched its latest flagship supercar, the F80. Not only is this a significant milestone in Ferrari’s performance evolution, it is also the first time its road car has introduced structural additive manufacturing (3D printing). components. The F80’s independent suspension system adopts a double wishbone layout, active internal shock absorbers, and uses additive manufacturing technology to manufacture the suspension arms, which provide strong support to improve the performance of the entire vehicle.

The F80’s active suspension system, considered one of Ferrari’s signature solutions for managing vehicle dynamics in all road or track conditions, has been completely redesigned. This innovative solution offers several benefits, including an optimized layout, more precise wheel control, a reduction in unsprung masses, the removal of anti-roll bars and the introduction of a dedicated camber correction function.

Active suspension systems address two seemingly irreconcilable needs: the need to maintain an extremely smooth ride on the track and minimize changes in ride height, and to effectively absorb road irregularities during daily driving. At low speeds, the system prioritizes mechanical balance and center of gravity control; As speed increases, the ride height control and active aerodynamic system work together to optimize aerodynamic balance.

During emergency braking (for example when entering a bend), the system minimizes height changes and avoids instability caused by forward weight movement. When cornering, the system increases downforce to maintain optimal balance; When exiting a corner, the system balances the rearward tendency to ensure traction and stability for all four wheels.

The F80 features a hybrid system consisting of a 3.0-liter V6 internal combustion engine and a hybrid electric motor, with a combined output of up to 1,200 horsepower, making it the car most powerful road car ever produced by Ferrari. The F80 accelerates from 0 to 100 km/h in just 2.15 seconds and can reach a top speed of 350 km/h.

The F80 is limited to a global production run of 799 units and the official price is around $3.9 million. However, it is reported that all vehicles have been sold out and have been acquired in advance by collectors and supercar enthusiasts around the world.

It is worth noting that McLaren has already introduced additive manufacturing technology into the suspension system of the W1 supercar. The advent of the Ferrari F80 once again proves the application potential of additive manufacturing in the field of high-performance automobiles and shows a new direction in future automobile manufacturing.