The frustrating reality of weak layers in 3D printing and how to fix it

This sinking feeling, with minimal pressure along the layer line when your 3D prints (which looks perfect on the outside). This is not just an aesthetic flaw. Poor layer adhesion fundamentally impairs the structural integrity of the printed object. Whether you are making functional components or creating end-use parts, strong interlayer bonding is non-tradable. understand Why For reliable high-strength prints, layers cannot stick together, and mastering the solution is crucial. As experts in the manufacturing of Greatlight industrial grade metal additives, we see these principles work every day on consumer-grade FDM/FFF printers.

Why is the layer adhered poorly?

The adhesion of the layer to its core is the result of a molecular bond between a continuous layer of thermoplastic (FDM/FFF) or a fusion metal particle (such as SLM). When thermal or mechanical conditions during printing are suboptimal, the force to separate the layers exceeds the bonding strength. Identifying the root cause is the first step towards intense printing.

Diagnosing and fixing weak layer adhesion: key strategies

1. Temperature: The basis of bonding (too cold is the culprit)

- Insufficient nozzle temperature: The plastic must flow freely to the previous layer and re-fusion it slightly. If the temperature is too low, it consolidates prematurely, thus preventing bonding.

- Make fixed: Gradually increase the nozzle temperature (5°C step). Refer to your filament specifications superior Range and experiment. A twisted corner? Keep balanced with cooling adjustment.

- The following cold layer: Printing a new layer to a cold surface prevents fusion.

- Make fixed: Make sure the printing bed temperature meets the filament requirements. Lack of fence? The cold layer of environmental draft? Use the printer housing to stabilize the temperature.

2. Materials Important: Select and handle silk wisely

- Absorb moisture: Thin filaments such as nylon, petg and even PLA are like sponges. Steam explosion during printing destroys flow and bonding.

- Make fixed: Dry silk before use! Store in a sealed bag with desiccant. The special filament dryer works best.

- Incompatible or low quality: Some materials have poor inherent bonding. Brittleness, fine filaments make the problem more complicated.

- Make fixed: Use a well-known filament brand that suits your application. Don’t rely solely on cheap filaments to achieve functional parts. Greatlight selects only certified metal powders – consistency is crucial.

3. Squeeze: It’s all about process and placement

- Inadequate sorting: If the printer does not provide enough material, the thin chains will not be fully integrated.

- Make fixed: Calibrate electronic steps accurately. Check for nozzle clogging, extruder gear tension, grinding wire or PTFE thermal gap. Ensure consistency of filament diameter in the slicer setup.

- Large floor height: Great for speed, but greatly reduces squeeze and contact areas.

- Make fixed: The nozzle diameter of the structural parts is ≤50-75% and the layer height is ≤50-75%.

- Print too fast: Move faster, flow and bonds than the material.

- Make fixed: Reduce printing speed, especially perimeters and fillers. Generally, the temperature is slightly raised.

4. Cooling: A delicate balance

- Overcooling too early: The blower cooling wire is bonded to the underlying layer before it is bonded.

- Make fixed: Disable or minimize the first 1-3 layers of cooling. use Minimum layer time Small layers are arranged to prevent premature blasting of them with air. Gradually increase the fan speed beyond the layer.

5. Slice Settings: Fine-tune bonds

- Inadequate shell penetration (skin overlap/filling overlap): Inadequate overlap between the exterior wall and the fill will reduce bonding contact.

- Make fixed: Increase "Fill/skin overlap" In your slicer (usually 5-20%).

- Weaker fill mode: Simple mesh provides support over cubes, capability or triangle fill.

- Make fixed: Use more complex 3D fill modes to achieve structural strength.

6. Hardware issues: Maintenance is key

- Partially blocked nozzle: The restriction flow is inconsistent, resulting in weaker spots.

- Make fixed: Regularly cold pull. Replace severe nozzles.

- Swing shaft/loose belt: Vibration artifacts can lead to inconsistent layer deposition.

- Make fixed: Tighten the belt (should be twisted) to ensure the hub is smooth and secure the frame bolts.

- Wire path friction: Integrated filaments create inconsistent feeding pressure.

- Make fixed: Lubricate the extruder gear (Teflon Spray). Ensure smooth wires and eliminate tight bends near the extruder.

Conclusion: One layer establishes strength

Achieve optimal layer adhesion is a systematic process of eliminating variables. It starts with the basic elements – the correct temperature and well-prepared materials – and is based on precise extrusion, balanced cooling and intelligent slicer setup. Consistent machine maintenance is not negotiable. Remember that power is more than just filling percentages; it’s about the quality of the bonds that hold each layer together.

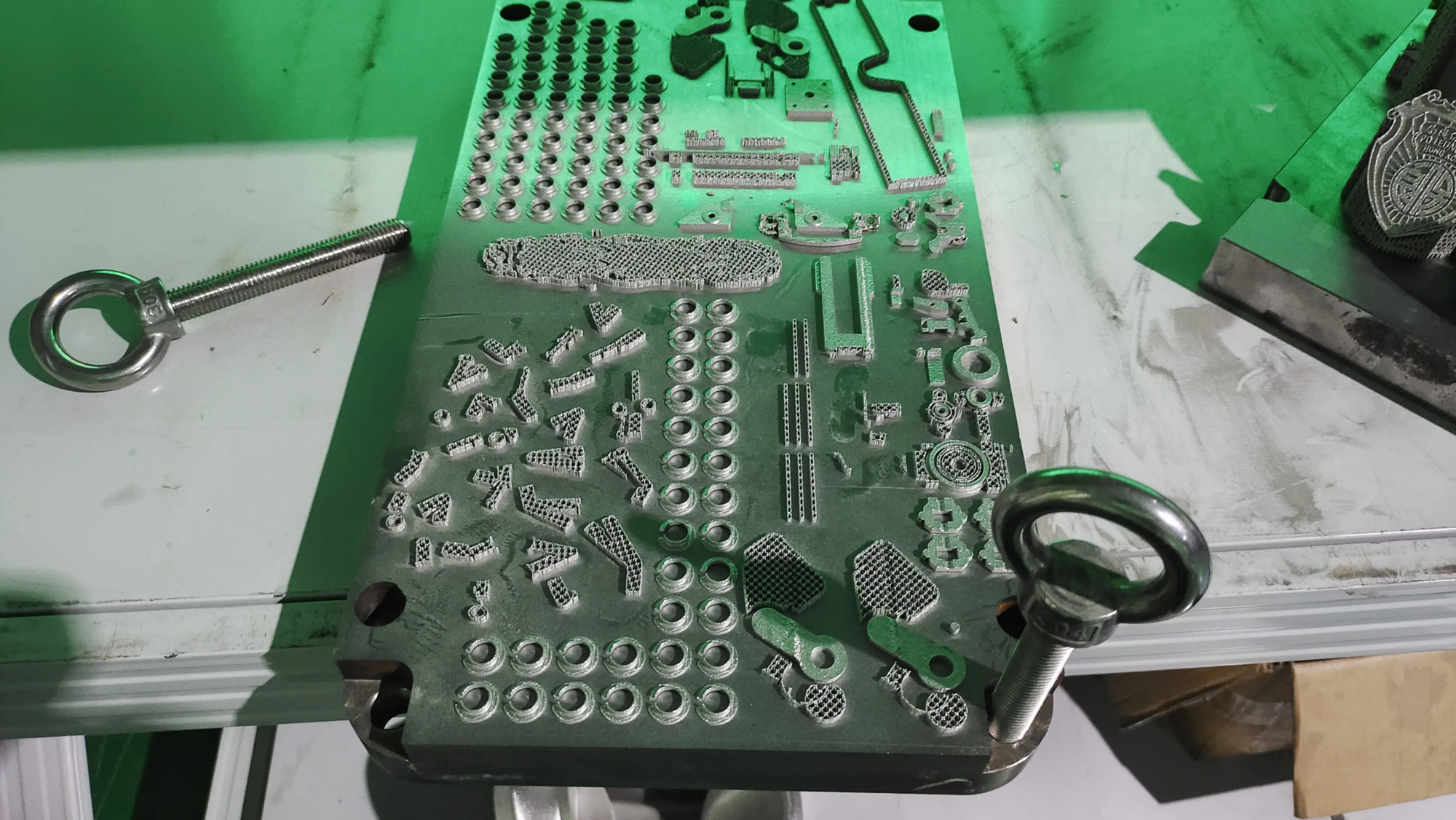

exist Greatwe elevate these principles to industrial standards. With state-of-the-art metal SLM printers, a tightly controlled processing environment, and deep expertise in materials science, we eliminate adhesion problems from scratch. We specialize in research Production of powerful high-precision metal components to require prototypes and production applications. Our one-stop service extends to comprehensive post-processing, including stress-relieving heat treatments and enhanced mechanical properties, ensuring excellent strength and accuracy needs from critical aerospace bays to complex medical tools. Most materials can be customized and processed at significant speeds.

FAQ: Deep water near 3D printed layer

Q: I’ve tried to raise the temperature, but the layers are still split. What now?

A: Extremely high heat can cause degradation and ooze, and sometimes weaken the layer. Make sure the cooling does not offset the heat (running the heat with a low/fanless fan on the layer in question). Double check for partially blocked squeezing calibration and nozzle. Finally, consider material selection – some filaments have weak interlayer strengths in nature.

Q: ABS layer bonding is terrible, without fences. Why do you need a sticky fence?

A: ABS cools quickly and is easily distorted. Warp the lifting edges and create gap layers without bridging. The housing remains stable, warm ambient temperature (usually 40-60°C+), significantly reducing warpage and ensuring that the layers remain hot enough for longer than the printer on the power-on printer.

Q: Yes "Ironing" or "Ironing top surface" Can the settings in my slicer improve layer adhesion?

A: Ironing top By running the heat nozzle above without squeezing. It does not affect the bond strength between the vertical layers. Focus on temperature, flow rate and cooling foundations to improve adhesion.

Q: What is the percentage of filling In fact Influence layer-to-layer strength?

A: The high fill provides more bonding surface area between the fill filler and the next flat layer. Low fill means that each solid layer is primarily located on sparse dot-like contacts. purely Between the layers Bond strength, higher fillers (40%+) will usually help. But a strong skin bonding setup is just as crucial as a wall count.

Q: My PETG print is strong, but has a distinct layered separation line on the sides. Is this weak?

one: This is usually a surface artifact ("Salmon skin," Z-applied) Inconsistent due to moisture, resonance or extrusion. If surface finish is the main problem, use blurred skin. Run functional strength tests by emphasizing the project – the line may be cosmetics. Always dry the PET thoroughly first. If the strength is indeed compromised despite the dry wire and the correct temperature, re-squeeze the calibration and stable mechanics.- Q: How long will moisture affect sensitive filaments such as nylon? Can I dry successfully?

A: Unsealed nylon can absorb harmful moisture Hour In wet conditions. Symptoms include popping sounds, blurred surfaces, and huge losses of intensity/juiciness. Use a dedicated dryer (Nylon at 70-80°C for 4-8 hours) – The conventional oven can burn the filaments. Store it in a vacuum sealed package with heavy drying after drying.

Struggling with consistent strength or dimensional accuracy in metal prototypes? Don’t compromise on part performance. Greverligh offers end-to-end professional rapid prototyping and production. Our advanced SLM technology, which combines strict quality control and extensive post-processing capabilities including annealing to reduce pressure and higher interlayer fusion, ensures parts perform reliably under pressure. Contact us now to get a quote and experience the differences in professional manufacturing.