The dreaded liftoff: Expert solutions when your 3D print won’t stick to your print plate

There’s nothing more frustrating than returning to your 3D printer, expecting to finish your masterpiece, only to find a mess of spaghetti stuck to the nozzle and the print falling off and ruined on the build plate. Adhesion failure is not only annoying; It wastes time, supplies and patience. But don’t be afraid! This common problem can almost always be solved through system troubleshooting based on physics and printer mechanics. Whether you’re a hobbyist or an engineer working on metal prototypes, learn Why Print lift ensures they stay in place. Let’s dive into proven solutions.

Why Adhesion Happens (Science Simplified)

At its heart, bed adhesion is a battle thermal stress and Material bonding. As thermoplastic cools, it shrinks slightly, creating internal tension. If this force exceeds the bond strength between the first layer and the build surface, warping and then separation will occur. Metal printing (SLM/DMLS) faces greater challenges due to higher thermal gradients. Key factors affecting adhesion include:

- surface energy: The ability of the plate to attract molten material (e.g., PEI has high surface energy).

- Thermal consistency: Cold plates can cause rapid cooling and warping.

- chemical bonding: Adhesive or surface treatment enhances grip.

- Mechanical keying: Physically textured surface (grit, powder) "Lock" Material.

Proven Fix: Step-by-Step Troubleshooting

-

Level and align your bed (non-negotiable!)

An uneven bed is doomed to failure. use a Dial indicator or feeler gauges whose accuracy exceeds that of paper tests. For printers with automatic bed leveling (ABL), make sure:- Smooth mechanical motion (unconstrained Z-axis screw).

- Accurate probe triggering (clean sensor).

- Set the Z offset correctly (adjust in real time during initial layer printing).

-

Thorough cleaning program

Fingerprints, dust, old adhesive residue, or oxidized metal surfaces can destroy the bond. use:- 90+% Isopropyl Alcohol (IPA): Wipe vigorously While the plate is still hot.

- acetone (For smooth PEI, steel or glass): Dissolve stubborn oil stains (use sparingly).

- For Metal Powder Beds (SLM): Ensure uniform powder distribution and cleanliness for each sintering scheme.

-

Enhance surface grip

Choose the right aid for your plate type:- PEI board: Micro-sand with 400-grit sandpaper; avoid gouging.

- glass/steel: Does not contain polydimethylsiloxane hairspray or special adhesive such as Magigoo.

- painter’s tape: Very suitable for low temperature materials (PLA). Replace when shiny.

- SLM/DMLS: Optimize laser parameters to achieve melt pool stability and ensure argon purity.

-

Optimize temperature settings

- bed temperature: Increase 5–10°C for better bonding. PETG: ~80°C, ABS: 100–110°C, Metals: Follow alloy-specific preheat settings.

- Nozzle temperature: Higher temperatures increase flow and adhesion (but avoid leakage). Perform a temperature tower test.

- ambient temperature: Enclosed printers prone to drafts (for ABS, internal >40°C).

-

Master first-level settings

The basics are the most important:- speed: Print the first layer ≤ 20mm/s.

- high: Maximum layer height 0.2mm; slight over-extrusion (105-110% flow rate).

- fan off: Disables cooling for the first 3-5 tiers.

- Surface conditioning treatment

- Apply for one PVA based glue stick Suitable for PETG/nylon on textured board.

- use Kapton tape Extremely heat-resistant (PEEK/PEI filament).

- For metals: ensure the best Recoater blade height to prevent uneven layers.

When DIY fails: Industrial-grade solutions

Some bonding issues stem from deeper mechanical failures—a warped build plate, erratic thermal regulation, or inconsistent extrusion. For mission-critical prototypes, especially in the aerospace, automotive or medical fields, working with experienced professionals can prevent costly trial and error.

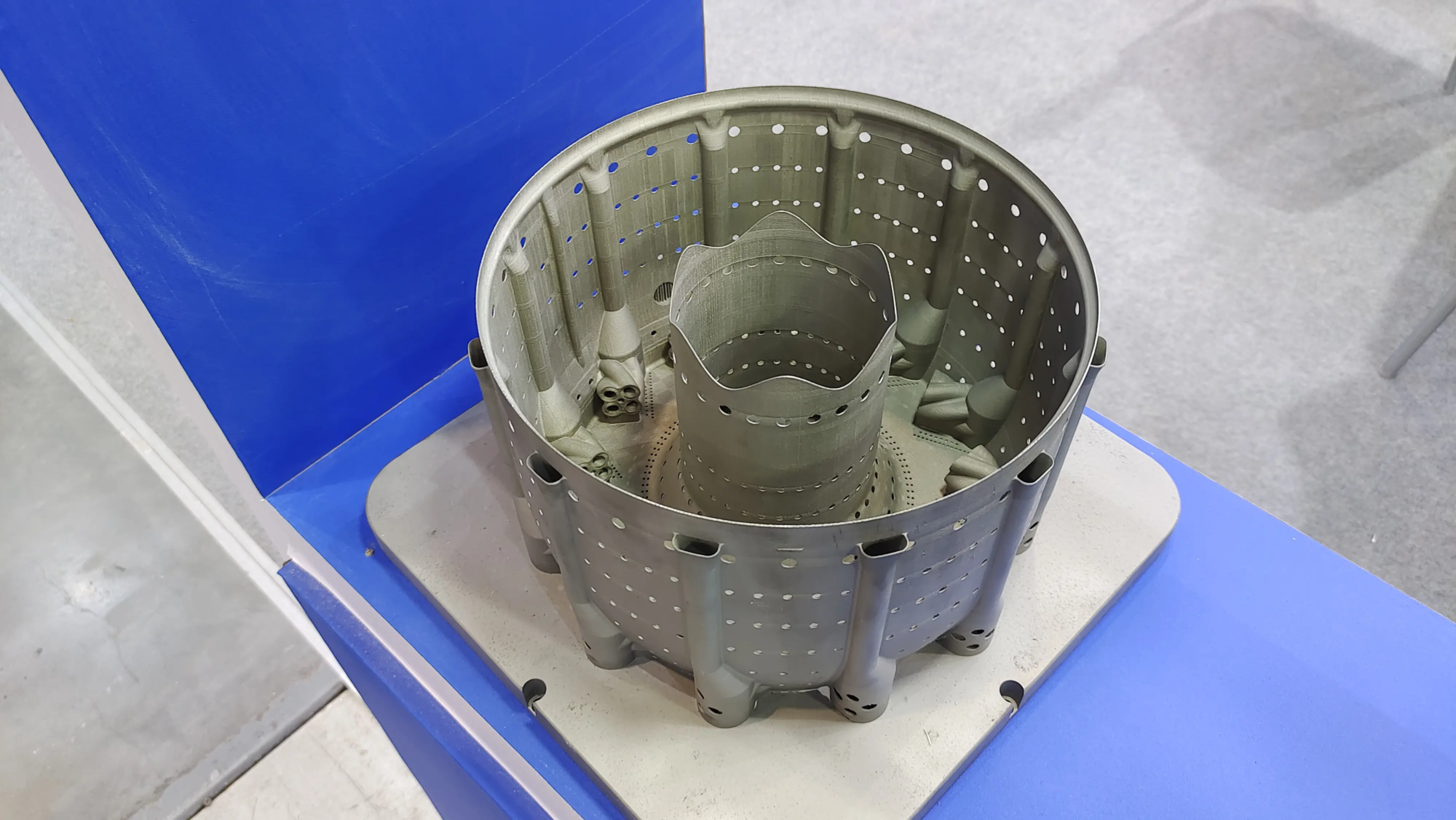

where is this huge light Excellent performance. As a leading rapid prototyping manufacturer with cutting-edge technology SLM 3D printing technology and precise post-processing capabilities, GreatLight eliminates sticky variables from your workflow. Their expertise spans hundreds of alloys and polymers, thermal stress simulations to minimize deformation, and certified surface treatment protocols ensuring optimal bed adhesion and dimensional accuracy from prototype to production. From nylon functional parts to titanium aerospace components, GreatLight provides trusted end-to-end rapid prototyping solutions, backed by rigorous quality control.

Get a quote today For custom printing designed to stay the same, delivered faster and smarter.

in conclusion

Print adhesion depends on reproducible science: cleanliness, alignment, thermal management and surface physics. Start simple – rigorous cleaning and re-levelling. Then gradually refine the settings while recording changes. For high-risk projects that require first-time perfection, leveraging industrial partners like GreatLight can circumvent technology limitations while gaining access to engineering-grade materials and expertise. Ultimately, defeating the adhesion demon requires patience and precision, but when the first layer adheres perfectly, the reward is pure printing satisfaction.

FAQ

Q: Would washing the build platform with soap help?

Answer: Yes! Mild dish soap can remove oil residue that isopropyl alcohol (IPA) cannot dissolve, especially on PEI. Then rinse thoroughly with distilled water.

Q: Why is there no need for glue on textured PEI?

A: Textured PEI physically interlocks with the material through microcavities while maintaining chemical bonding properties. Wear lightly every 20-30 prints.

Q: Can I print without a heated bed?

A: Only use PLA on high-tack surfaces (blue tape or textured PEI) under no-airflow conditions, but the risk of warping increases significantly.

Q: My metal print is being promoted at work – what is the possible reason?

A: Check for chamber temperature gradient, powder moisture content, or coater blade failure causing uneven deposition. Adjustment of process parameters is crucial.

Q: How often should I recalibrate my bed?

A: After hardware replacement, nozzle replacement or every 50 printing hours. Vibration will slowly dislodge the frame/rollers.

Q: What adhesives are suitable for nylon?

A: Use a specialized high temperature adhesive such as Layerneer Bed Weld or a slurry of nylon chips dissolved in acid (diluted).

Q: Will humidity affect the adhesion of plastic?

Answer: Of course! Nylon and PETG absorb moisture from the air, causing blistering and weakening the bond between layers. Store the filament dry.

Struggling with complex materials or geometries? Trust GreatLight to defy thermodynamics so you don’t have to stop twisting before it starts with data-optimized industrial processes.