Embrace flexibility: Mastering silicone-like 3D printing with advanced filaments

Continuous developments in 3D printing continue to push the boundaries of materials science. One of the most exciting developments is the rise of flexible filaments capable of mimicking the unique properties of silicones, opening the door to applications requiring elasticity, impact resistance and biocompatibility. While true Liquid Silicone Rubber (LSR) printing remains niche and complex, these specialized flexible filaments offer incredible accessibility and versatility for creating functional prototypes, end-use parts and specialized assemblies. "bounce back."

Silicone Dreams: Why Direct Processing Is Challenging

Silicone rubber is favored across industries for its exceptional combination of properties: exceptional flexibility over a wide temperature range, excellent biocompatibility, UV and chemical resistance, electrical insulation and skin safety compliance. However, tradition Additive manufacturing There are significant obstacles to pure silicone:

- Material status: Silicone begins as a liquid resin or paste. Printing requires specialized deposition systems (such as screw pumps) rather than the common thermoplastic extrusion systems used in FDM/FFF printers.

- Curing mechanism: Silicone requires heat (thermoset) or UV light (UV cure) to permanently cross-link and cure after deposition. This requires integrating post-deposition curing systems into the printer or secondary cure process.

- Hardware barriers: Few commercial desktop FDM printers are designed to handle viscous liquid silicones. Specialized equipment (usually industrial equipment) is often required.

Although dedicated silicone 3D printers exist, their cost and complexity put them out of reach for most users. Enter the ingenious alternative: flexible thermoplastic filament.

Flexible filament: narrowing the performance gap with silicones

Recognizing the need for flexible parts that do not require industrial silicone printers, materials scientists developed thermoplastic elastomer (TPE) filaments designed for use with standard FDM/FFF machines. They are solid at room temperature but soften and become pliable when heated.

- TPE (thermoplastic elastomer): This broad category covers materials that combine rubber-like elasticity with thermoplastic processing properties.

- TPU (thermoplastic polyurethane): He is, without a doubt, the most distinguished member of the family. Known for its excellent balance of flexibility, strength, abrasion resistance and layer adhesion. It is available in a variety of hardnesses (Shore A 60-95+).

- TPC (Thermoplastic Copolyester): Usually has higher temperature resistance than TPU.

- Special flexible materials: These include advanced TPEs specifically engineered to be soft, elastic and even biocompatible (look for grades that meet USP Class VI or ISO-10993 standards). Some proprietary blends may even contain silicone ingredients or additives that mimic silicone.

accomplish "Silicone-like" Filament characteristics:

While they can’t perfectly replicate every nuance of pure silicone, high-quality TPU and advanced TPE can deliver dramatic results "similar to silicone" Features critical for many applications:

- High elasticity: Parts can stretch significantly and repeatedly return to their original shape without permanent deformation.

- Softness: Offers low Shore hardness values (even as low as Shore A 60-70, mimicking soft silicone) for comfortable grip, sealing and cushioning.

- Impact and abrasion resistance: TPU is particularly good at this, providing durable parts that can withstand drops and scratches.

- Chemical resistance: Similar to silicone, it is resistant to a wide range of oils, greases and chemicals.

- Biocompatibility options: The selected filaments undergo rigorous biocompatibility certification testing, which is critical for applications in contact with human skin or within medical devices.

- Sealing and shock absorption: Ideal for gaskets, seals, shock absorbers and protective components.

Where "Printed silicone" Excels: Practical Application

The ability to 3D print flexible functional parts opens up innovative uses that rigid plastics cannot address:

- Prototyping: Rapidly iterate on functional seals, gaskets, handles, ergonomic interfaces and flexible housings to dramatically speed design verification.

- End use features: Produces custom cell phone grips, cable strain reliefs, remote control vehicle suspension components, shoe midsoles (prototypes or low volume), padding elements, soft robotic components and specialty tool pads.

- Custom seals and gaskets: Create custom seals for housings, ductwork, or automotive applications with complex geometries not possible with traditional methods.

- Medical and wearable devices: Biocompatible grades are available for custom prosthetic liners, wearable medical device interfaces, massage tool attachments and assistive tools (end use subject to regulatory approval).

- consumer goods: Soft-touch handles, protective covers, flexible hinges, toy parts and decorative flexible elements.

Mastering Printing: The Secret to Success with Flexible Filament

Compared to rigid plastics like PLA or ABS, printing with flexible materials requires adjustments:

- Direct drive extruder: Crucial for precise control. Bowden setup is difficult, resulting in under-extrusion, gaps, and inconsistent flow due to filament compression. exist huge lightour advanced printers feature an optimized direct drive system for demanding filaments.

- Printing speed is slower: Flexibility means less rigid push. Print at a slower speed (usually half the speed of PLA or less) to achieve proper extrusion control.

- Optimize retraction: Minimize the retraction setting to prevent filament bending inside the extruder. For flexible materials, disabling retraction completely often produces better results.

- Minimize printhead movement: enable "Combed" or "Avoid using printed parts when traveling" This prevents the nozzle from dragging across the printed flexible surface, which could easily deform it.

- Heated bed: Necessary for proper bonding. Use PLA temperature or slightly higher.

- Bed adhesion: PEI sheets/powder coated beds work great. Blue painter’s tape or a special flexible adhesive spray can also help. Avoid excessive edges/rafts as they are difficult to remove cleanly.

- Comes with printer: Helps maintain stable temperatures and reduces the risk of warping.

- Dry filament: The flexible filaments strongly absorb moisture. It should be dry and thoroughly dried before printing to avoid bubbling and inconsistent extrusion.

- Custom settings: Increase extrusion temperature conservatively (within manufacturer’s recommendations) to improve flow. Make sure the extruder tension is set correctly – tight enough to clamp but not deform.

Pros, Cons, and When to Choose Printed vs. Molded Silicone:

- Flexible filament printing (TPU/TPE):

- advantage:

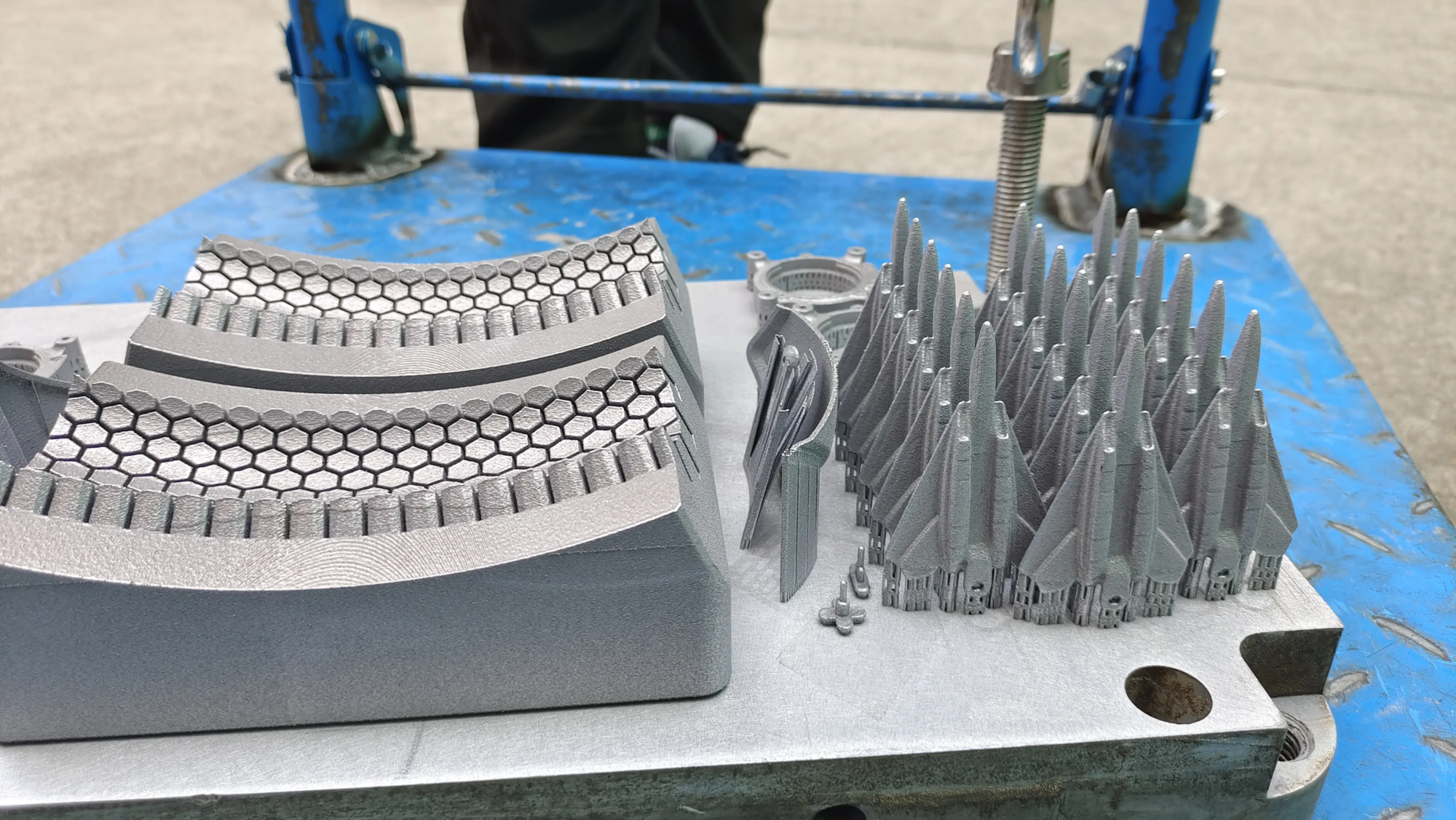

- Excellent design freedom for complex geometries.

- Rapid prototyping and low-volume production.

- Leverage existing FDM hardware (after upgrade).

- Available in a variety of hardnesses and properties.

- Cost effective for complex custom parts and prototypes.

- shortcoming:

- Resolution/Layer Lines: Visible layer lines affect surface finish and sealing surfaces.

- Anisotropy: Strength will vary slightly depending on the direction of printing.

- Material Limitations: Maximum softness and elongation are typically less than high-end true silicones.

- Production volume: Compared to molding, high-volume production is not economical.

- advantage:

- Injection molded silicone:

- advantage:

- Superior smooth surface, isotropy, ultimate elasticity/tear strength.

- Economical for very high production volumes.

- Best-in-class biocompatibility option.

- shortcoming:

- The processing cost of molds is relatively high and requires a large amount of upfront investment.

- Post-processing design changes are difficult and expensive.

- Not suitable for rapid prototyping or custom/low-volume parts.

- advantage:

judgment:

Part of the choice comes down to purpose: Need to quickly and affordably customize complex geometries for low-volume or prototyping? Flexible filament is a game changer. Need thousands of identical parts with perfect surface finish and ultimate performance? Traditional silicone molding wins. GreatLight is good at controlling this decision tree, Delivering advanced additive manufacturing solutions using filament-based technology "similar to silicone" Materials and comprehensive support turn successful prototypes into molded silicone production, truly providing end-to-end rapid prototyping and manufacturing flexibility.

Conclusion: The flexible future is printed

Flexible filaments, especially TPU and advanced silicone-like TPEs, represent a paradigm shift. They democratize the manufacture of resilient, durable, functional parts that were previously the sole domain of expensive manufacturing processes. While they won’t replace real silicones in all applications, especially high-volume production, their ability to unlock complex designs, quickly iterate through prototyping, and deliver end-use performance directly from an accessible desktop printer is transformative.

Understanding the nuances of material selection—from shore hardness and biocompatibility to printing mechanics—is key. Mastering specialized printing techniques ensures success. By leveraging these materials, designers and engineers are pursuing innovations in medical devices, soft robotics, wearables, consumer products, and industrial applications with unprecedented agility. Flexibility is no longer a barrier; thanks to these advanced filaments, it enables smarter design and manufacturing.

FAQ: Flexible Filament and 3D Printing "silicone"

-

Can I 3D print real silicone on a regular FDM printer?

- Generally speaking, No. Pure liquid silicone requires specialized printer technology to deposit and cure it. Standard FDM printers extrude thermoplastic filament rather than liquid resin/slurry.

-

What is the best filament to mimic the properties of silicone?

- TPU (thermoplastic polyurethane) are the most popular and easily available, offering the perfect balance of flexibility, strength, durability and printability. For softer, more realistic silicones or biocompatibility, look for Advanced Imitation silicone TPE (thermoplastic elastomer) Sold by professional filament manufacturers offering certifications such as Shore A60 hardness or ISO 10993 biocompatibility.

-

How flexible is TPU/TPE filament?

- Flexibility varies. Hardness is measured on the Shore A scale. Common TPUs range from Shore A 60D (fairly hard) to Shore A 85 (very flexible). The hardness of imitation silicone TPE can be as low as Shore A 60-70, and it feels very soft and flexible. The lower the Shore A value, the softer/more pliable the material.

-

Is TPU/TPE filament food safe?

- The filament itself may be chemically food safe inert Once printed. However, FDM printing creates tiny pores where bacteria can thrive and cannot be adequately cleaned. so, Printed parts are generally not considered food safe Unless specifically certified for food contact and Properly handle/seal after printing. Biocompatibility does not automatically equal food safety.

-

Do I need a special printer to print flexible filament?

- A direct drive extruder is almost a must. Bowden extruders are in a tough spot. Many printers can be upgraded. For best results, printers designed for flexibility are best. A sturdy extruder, minimal retraction, a closed build chamber, and precise temperature control are very beneficial.

-

Why is it so difficult to remove stringing/oozing?

- Due to its viscosity when hot, flexible filament bleeds much more than rigid plastic.

- Solution: Minimize aggressive retraction; optimize temperature; print cooler; maximize travel speed; use printer features such as "slide" or "wipe"; Carefully clean up after printing.

- Are flexible filament fumes toxic?

- The specifics of the filament are important. Many brands of TPU prints have a strong smell. Choose filament from a reputable manufacturer that adheres to safety standards. thermoplastic polyurethane