Bringing Five Nights at Freddy’s to Life: The Ultimate Guide to 3D Printing FNAF Collectibles

With its dark corridors, unsettling animatronics, and heart-pounding gameplay – Freddy Fazbear’s Pizza – Five Nights at Freddy’s (FNAF) has attracted legions of loyal fans. For many enthusiasts, the excitement transcends the screen and enters the tangible world. Creating your own complex FNAF characters via 3D printing provides an unparalleled immersion and customization experience. Whether you dream of a highly detailed Springtrap statue, a set of miniature cupcake toppers, or even stop-motion articulated characters, 3D printing can make your dreams come true. This guide delves into the exciting world of FNAF 3D printing, giving you the knowledge to transform your digital nightmare into a physical collectible.

The charm of FNAF 3D printing

Why has FNAF become such a popular subject in the 3D printing community?

- In-depth character design: FNAF’s animatronics feature unique, easily recognizable, and often complex designs – from the classic charm of Freddy Fazbear to the terrifying teeth of Nightmare Freddy. These intricate details are a perfect challenge for 3D printers.

- Creative expression: Printing allows fans to personalize the universe. Want a different color scheme for Pirate Bay Fox? A Phantom Smasher with glowing eyes? Maybe it’s stylized and cute. "chibi" A version of Kim Freddy? 3D printing unlocks unlimited creative potential.

- Community and sharing: Thriving online communities on platforms such as Thingiverse, Cults3D and MyMiniFactory continue to create and share carefully crafted FNAF models. It’s a passionate, collaborative ecosystem.

- Tangible collectibles: In addition to digital art or posters, 3D printed animatronics provide unique physical centerpieces. Color it, light it, modify it – the result is a one-of-a-kind piece of franchise memorabilia.

- Role play and props: For cosplayers, 3D printing is invaluable in creating accurate masks, helmets, hands, and intricate costume details that capture the essence of these iconic characters.

Your FNAF 3D Printing Journey: A Step-by-Step Tutorial Roadmap

Transforming digital FNAF models into high-quality physical objects involves several key stages. An overview is as follows:

-

Procurement model: This is the basis.

- Repository: Start with popular sites like Thingiverse, Cults3D, MyMiniFactory, and Printables. search "fornuff," Specific character names, and even levels of detail/clarity.

- Model quality: Check reviews, photos of prints, and the reputation of the designer. Look for models with clear printed instructions, supports (if needed), and well-designed geometry. Beware of low polygon models or poor topology, they may be difficult to print cleanly.

- Paid and free: Excellent free models exist, but premium models often offer superior detail, clarity, and pre-supported files. Consider supporting talented artists whose work you love.

- Modify (optional): Advanced users can use software such as Blender or Meshmixer to customize existing models – resize, combine elements or add personalized details.

-

Prepare to print (slice):

- Slicing software: Import the STL file of your choice into the slicing software (Cura, PrusaSlicer, Simplify3D, etc.).

- direction: Strategically orient the model to minimize overhang (avoiding over-support), optimize strength (especially for thin limbs), and ensure optimal surface finish in key areas such as the face.

- support: FNAF models often have significant hanging parts (ears, limbs, wires, accessories). Your slicer can generate supports. It is critical to adjust support settings (density, pattern, interface distance) to balance print success with ease of removal and surface quality. Seeing Freddy’s head destroyed by improperly removed supports is a nightmare best avoided! Consider manually placing supports in critical areas.

- Layer height and resolution: Finer layer heights (e.g. 0.1-0.15 mm) produce a smoother surface but increase print time. For characters that are rich in detail, this is usually worth it. Adjust based on the complexity of the model and your tolerance for layer lines.

- filling: Determines internal sturdiness. For display models, 15-25% is usually sufficient. Higher fill adds weight and strength but uses more material and time.

- Material considerations: PLA is the first choice for beginners – easy to print and available in a variety of colors/finishes (standard, matte, silk, glow-in-the-dark, wood). ABS/ASA offers greater durability and temperature resistance, making it ideal for props or parts that require strength but require an outer shell and better ventilation. PETG is a good middle ground: tougher than PLA, more odorless/harder to warp than ABS. Resin printing (SLA/DLP) allows for extremely smooth, high-detail surfaces ideal for micro-animatronics or complex parts, but requires safety precautions (gloves, ventilation) and post-processing.

-

Printing process:

- Bed adhesion: Make sure the bed is clean and level. Use the appropriate adhesion aid: glue stick, hairspray, or specialized bed adhesive for your specific printer/material.

- Printer adjustments: Calibrate extruder E-steps and filament flow rate. Make sure the belt is taut and all moving parts are lubricated. A stable ambient temperature will help.

- monitor: Especially during the critical first layer and long print runs. Use tools like OctoPrint for remote monitoring via camera.

- patience: Complex FNAF models can be many Printing takes hours, sometimes days. Make sure your printer is in a safe, stable environment.

- Post-processing: achieve showroom effect

- Support removal: Carefully remove all support structures. Flat end mills and various picks/dental tools are priceless. Work slowly to avoid catching details. Support contact points may require grinding.

- Polishing: Progressively smooth layer lines, artifacts and defects through different granularities (low to high: 120 -> 220 -> 400 -> 600+). The attention to detail greatly influenced the final paint job.

- Gap filling (if needed): For visible seams (common on multi-part models) or layer lines that require a lot of fill, use a modeling putty (such as Tamiya Putty) or an epoxy (such as Milliput). After curing, sand it smooth with sandpaper.

- Clean (resin): Resin prints must be cleaned with isopropyl alcohol (IPA) and thoroughly cured under UV light according to the manufacturer’s instructions.

- Primer: Apply a high-quality primer (spray or brush). This can reveal any remaining imperfections that need repair and provide an even, paint-adherent surface.

- painting: Artistry is on display! Use high quality acrylic model paint (e.g. Vallejo, Citadel, Tamiya). Techniques such as priming, shading/washing, highlighting, and dry brushing bring animatronics to life. See the countless YouTube tutorials on drawing FNAF models.

- Details and effects: Add weathering (dirt, rust, especially with characters like Springtrap or the Blighter), blood splatter, glowing eyes (use clear resin coated with fluorescent ink or micro-LEDs), fabric textures, and more.

- assembly: Carefully glue the multi-part model together using superglue (cyanoacrylate) or plastic cement (for PLA/ABS). Consider using small magnets for removable parts (e.g. heads, accessories).

- Finishing touches: Apply a protective clear coat (matte, satin or gloss) to seal the paint and increase durability.

Why partner with professionals like GreatLight to realize your FNAF ambitions?

While DIY 3D printing offers great satisfaction, achieving truly professional-grade results can be challenging, especially for demanding FNAF models with intricate mechanisms, micro-details, complex geometries, and the need for superior surface finishes.

where is this huge light Excellent performance. As a premier rapid prototyping manufacturer, we specialize in transforming complex digital designs into flawless physical realities. Our expertise is particularly valuable on challenging FNAF projects:

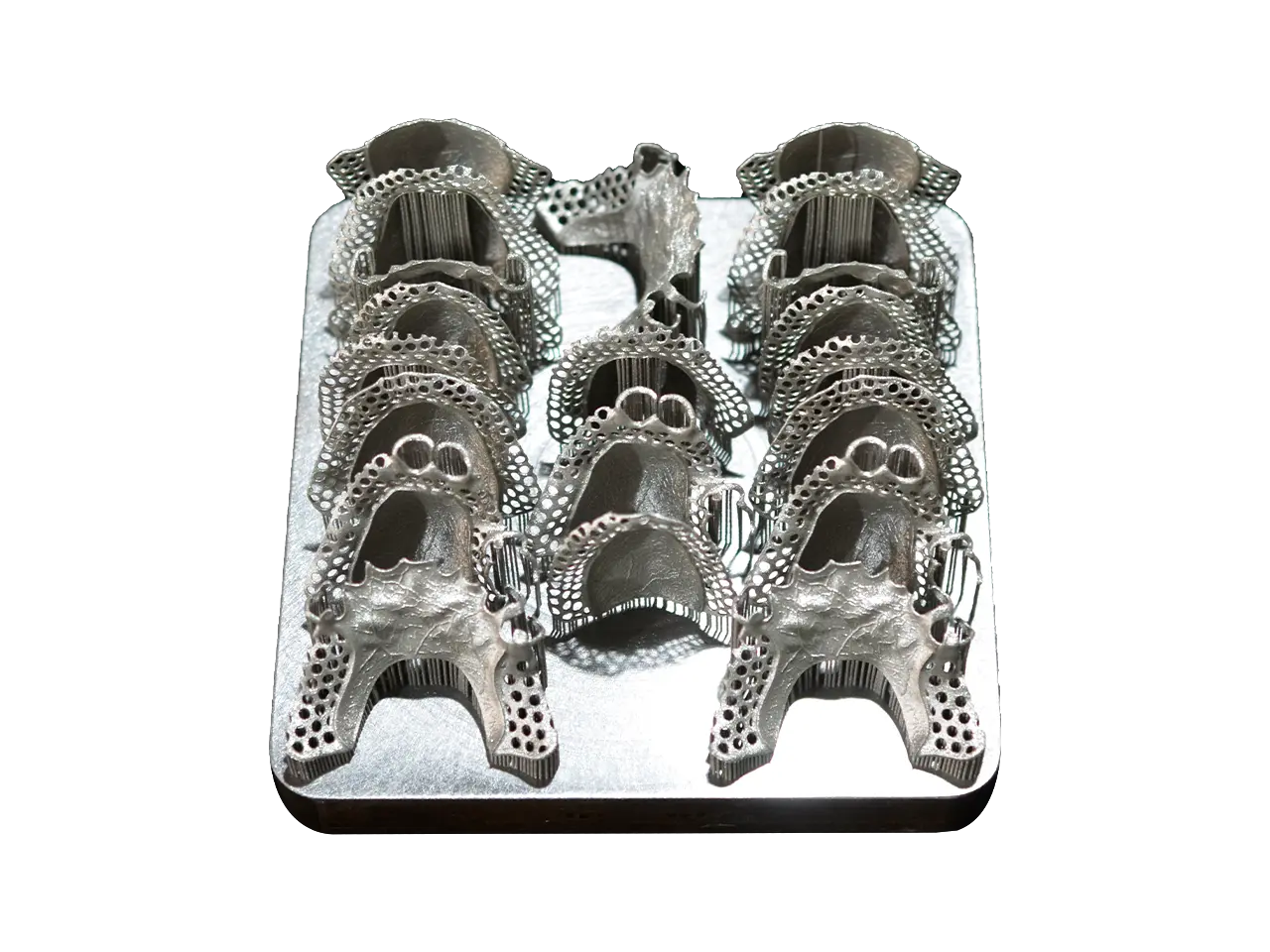

- Advanced SLM metal 3D printing: Need unusually powerful and detailed internal mechanisms? Parts that require complex metal components (such as custom joints, structural reinforcements, or decorative metal elements)? Our Selective Laser Melting (SLM) technology offers unparalleled advantages in manufacturing complex, durable and precise metal parts.

- Multiple technical expertise: In addition to metal, we offer a full range of polymer 3D printing technologies (SLA, SLS, FDM) to perfectly match your project’s requirements for detail, durability, flexibility or visual impact.

- Conquer complexity: Our team specializes in solving the toughest rapid prototyping problems. A deep understanding of design for manufacturability (DFM), support strategies for complex overhangs, and material behavior ensures successful launch of challenging FNAF models.

- Comprehensive post-processing: One-stop service is our logo. Our extensive post-processing capabilities extend far beyond basic sanding:

- Advanced finishing: High-quality professional grinding/polishing to achieve a near-injection molding effect.

- Painting and coating: Professional multi-stage painting, custom color matching, weathering effects, airbrushing and professionally applied protective clear coat.

- Industrial grade processing: Steam smoothing (for ABS parts), tumbling, electroplating, anodizing (for metal parts), etc. to obtain unique aesthetic or functional properties.

- Precision assembly: Proficient in assembling multi-part models, including plug-in mountings (such as lights) and ensuring perfect fit.

- Material Versatility and Speed: Access a vast material library (stainless steel, titanium, aluminum alloys, various engineering plastics, resins). We offer fast delivery times and flexible batch options, from single prototypes to small batches.

- Customized core: We understand that fans seek unique creations. We work closely with you to perfect the design, select the best materials and processes, and achieve the look and feel you envision for your FNAF masterpiece.

- Cost-effective precision: Leverage our industrial-scale efficiency and expertise. For complex projects that require high quality, working with GreatLight is often more economical than trying to iterate yourself and guarantees superior results.

Conclusion: From pixels to reality

3D printing has revolutionized the way FNAF fans interact with their favorite series. It allows you to go beyond merchandise and become a creator, making personalized, high-quality, and even interactive images of Freddy Fazbear, Chica, Bonnie, Foxy and their disturbing companions. While the DIY path is rewarding, embracing the journey requires patience, practice, and investment.

For projects where precision, complexity, material performance or a true museum-quality finish are critical, work with a professional rapid prototyping service such as huge light is the optimal solution. Our advanced SLM/SLA/SLS/FDM capabilities, unparalleled post-processing expertise and dedicated problem-solving ensure your most ambitious FNAF creations reach their full terrifying (or awe-inspiring) potential. So whether you embark on a DIY adventure or tap into expert knowledge, get ready to bring Five Nights at Freddy’s unique magic and menace into your world, one incredible layer at a time.

Frequently Asked Questions (FAQ) – FNAF 3D Printing

Q1: Where can I find the best free FNAF 3D models for printing?

A: Popular repositories such as Thingiverse, Printables, and Cults3D have many free FNAF models. Search by specific character names (for example, "FNAF fox," "spring trap") or similar terms "FNAF Articulation." Before you begin, be sure to check user reviews and photos of print results to gauge quality and printability.

Q2: Is PLA suitable for large FNAF statues? Or do I need a sturdier material?

A: PLA is great for smaller models or display pieces that are not under pressure. For larger prints (~30cm+) or articulated models/props, materials such as PETG or ABS/ASA are better choices as they offer greater strength, durability and temperature resistance, reducing the risk of warping or breaking. GreatLight can advise on the best materials for size and function.

Q3: Painting tiny details on FNAF figures can seem daunting. Any suggestions?

A: Buy a good quality fine paint brush (size 000 to 1). Use a good primer. Slightly thin the paint with water or thinner. Apply multiple thin layers rather than one thick layer. Master techniques like wash (diluted paint flowing into crevices) and dry brushing (gently brushing over raised areas with a nearly dry brush) to achieve highlights and shadows. Practice waste paper first! Honlaite’s professional spray painting services can achieve perfect results.

Q4: My printed FNAF model has visible layer lines. How can I get a smoother finish?

A: Use a finer layer height (such as 0.1 or 0.08 mm). Post-process with care: sand thoroughly (sanding through finer grit), apply filler primer (then sand again), and possibly solvent smooth (only for ABS/ASA with appropriate safety). Resin printing inherently provides the smoothest surface finish. For challenging projects, GreatLight’s industrial finishing process can completely eliminate layer lines.

Q5: Can GreatLight print and complete multi-part, complex FNAF models (such as articulated figures)?

Answer: Of course. Handling complex assemblies is our specialty. We specialize in printing many complex parts with high precision, ensuring a perfect fit. Our comprehensive post-processing includes meticulous support removal, extensive finishing (sanding, polishing), and professional painting/assembly to create a showroom-ready articulated collectible.

Q6: I only have an idea/sketch for a unique FNAF character or prop. Can Weiguang help?

Answer: Yes! We provide end-to-end support. Our team can assist with CAD modeling (reverse engineering from sketches/photos), material selection, design optimization for manufacturability, precision printing using the best technologies (SLM for metal parts, SLA for ultra-high detail, etc.) and complete professional finishing to realize your unique vision. Contact us for a custom quote.

Q7: How durable are 3D printed FNAF dolls, especially for role-playing and the like?

A: Durability depends heavily on the material and printing orientation/method. PLA is fragile; ABS, PETG and nylon (SLS/SLS) are more difficult choices for props. Engineering-grade resins or metals, such as those used by GreatLight through SLM, provide the highest durability. Reinforced internals and expert design optimization are critical for role-playing parts that can withstand stress, which is where GreatLight’s engineering expertise comes into play.