Navigating the complex world of food-safe 3D printing consumables: a comprehensive guide

The convergence of 3D printing and food-related applications (custom cookie cutters, unique cake toppers, custom spice racks, or prototype kitchen appliance parts) is certainly exciting. However, moving beyond novelty and actually engaging with consumables requires a critical understanding of one core principle: Not all 3D printed objects are food safe.

Declare any print objects "food safety" Very complicated. It depends on a synergy of factors: inherent material properties, meticulous printing processes, rigorous post-processing techniques, the purpose for which the product is designed, and most importantly, managing realistic expectations. This guide delves into these complexities, with a particular focus on being considered may fit For use in food contact applications.

Why 3D printing is not inherently food safe

- Microbial safe haven: Fused filament manufacturing (FFF/FDM) is the most common desktop printing method and essentially creates microscopic grooves and layer lines. These are perfect breeding grounds for bacteria and mold, making thorough cleaning nearly impossible.

- Material composition: Filament formulations often contain additives – colorants, plasticizers, stabilizers – whose long-term food contact safety is not always proven. Even the base polymer may contain impurities.

- Contamination risk: The printing process itself carries risks. Hot ends/nozzles (especially brass) can leach metals like lead. There may be dust, debris, or remnants from previous printing trapped inside the printer.

- Degradation and leaching: Factors such as heat (dishwasher, microwave, hot foods/liquids), UV rays, acids (ketchup, citrus), fats/oils, and alcohol degrade the filament over time, possibly releasing unwanted compounds.

Understanding Food Safe Filament: Key Categories and Considerations

the term "Food safety filament" Often used loosely. Greater precision lies in understanding the material Designed for potential food contact below specific conditions. Key aspects include:

- Base polymer: Which plastic forms the basis?

- additive: What additives are used? Are they FDA compliant?

- Certification: Does the manufacturer provide tangible evidence of compliance (e.g. FDA CFR 21, EU 10/2011)?

- Processing: How is filament made? Are additional steps taken to avoid contamination?

Potential food contact filament options (with warning):

-

PLA (polylactic acid):

- advantage: Biodegradable (under industrial composting conditions), derived from renewable resources (cornstarch/sugar cane) and generally considered safe in its pure form. Many FDA-compliant options exist.

- shortcoming: Low heat resistance (starts to soften at around 60°C and easily warps). It degrades over time with acidic foods or fats. It is crucial to: Most colored PLA contains unregulated dyes/pigments. Choose only natural/white PLA from manufacturers that clearly state FDA food contact/GRAS compliance. Avoid additives like shimmer or glow.

- Best for: cold/cold food (only!), Very Short-term exposure projects such as cupcake decorating (non-reusable knives), prototyping non-load-bearing kitchenware parts.

-

PETG (polyethylene terephthalate modified):

- advantage: FDA approved resin with excellent chemical resistance (alcohols, oils, dilute acids/alkalis), higher heat resistance than PLA (~70-80°C), hydrophobic (less hygroscopic).

- shortcoming: Almost all colored PETG contains dyes. Absolute prerequisite: Source filament is explicitly certified to meet FDA standards including dyes. Proper drying is required.

- Best for: Items that require better heat/chemical resistance than PLA: glasses, pitchers, storage containers (handle with care – restrictions). Again, give priority to certified natural/white colors if possible.

- Specific filaments meeting FDA standards:

- Some manufacturers offer filament exclusively:

- Use resin that meets FDA standards and Verified concentrations of compliant dyes/pigments.

- Produced under controlled conditions to minimize the risk of contamination.

- Provide documented evidence (certificate of conformity citing FDA CFR 21).

- Examples: Specialized PETG/PLA blends, PP (polypropylene requires special printing setup).

- advantage: highest confidence level within filament limits. Compliance Transparency.

- shortcoming: More expensive than standard filament. Still must be printed and sealed hygienically.

- Best for: Projects requiring higher assurance on prototype designs or limited contact appliances/labware.

- Some manufacturers offer filament exclusively:

Key factors beyond the filament itself

Understanding filament is just the first step. Achieving functional food safety requires solving the following issues all life cycle:

-

Special print settings:

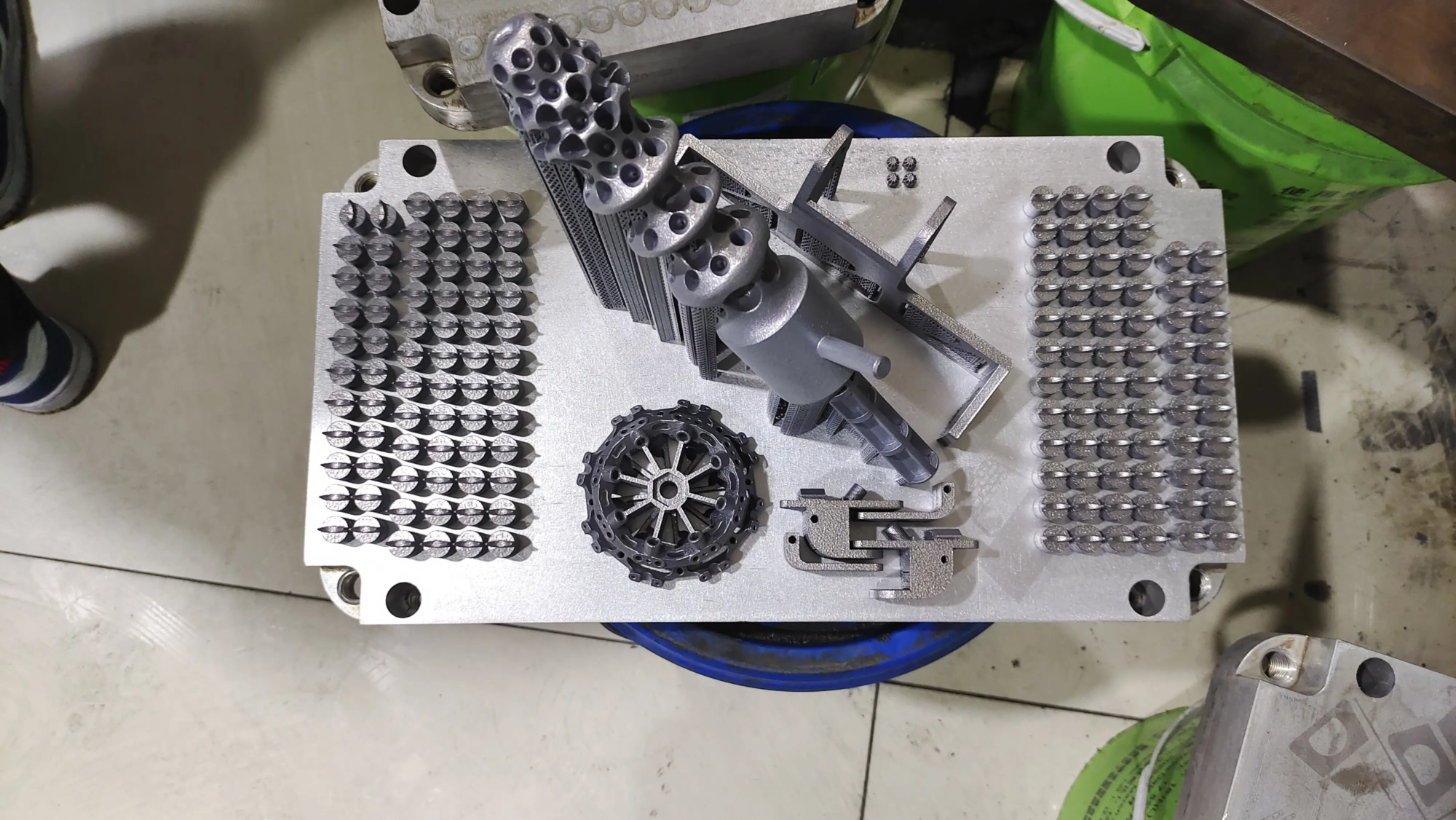

- Stainless steel nozzle: Basic. Brass nozzles contain lead, which can migrate into prints, especially from acidic foods. Hardened steel is acceptable, but stainless steel is preferred to minimize the risk of contamination. (Pro tips from metal pros: Companies like GreatLight, which specializes in aerospace-grade metal printing, often use ultra-clean, high-precision stainless steel processes that are inherently suitable for hygienic applications, demonstrating the critical role of metallurgy, even in filament printing peripherals.

- To clean the printer: Thoroughly clean the print platform and print chamber before performing any operation "food safety" The work of removing potential contaminants from previous prints.

- Print parameters: Optimize layer height (thinner improves surface smoothness slightly) and extrusion rate to minimize voids/filled gaps where food is trapped.

-

Imperative post-processing:

- Sealing surface: This is non-negotiable. coat print FDA approved food safe epoxy resin (Epoxy resin must Get certified! ). Apply carefully according to manufacturer’s instructions, ensuring complete coverage. This physically seals the micropores.

- Thorough cleaning: Before sealing and After sealing/curing, wash thoroughly with hot soapy water and dry completely. Cured coatings are generally dishwasher safe (check epoxy specifications).

- Design and use considerations:

- Avoid complex geometries: Simplify the design. Avoid sharp interior corners, complex latticework, or deep crevices that cannot be cleaned effectively. Smooth surface = safer surface.

- Practical purpose: Know the limitations. no way Use 3D printed items for high temperature cooking, microwave, dishwasher cleaning (unless specifically designed for epoxy), or prolonged contact with oily/fatty/acidic foods, or even sealing.

- Limited contact information: Treat the project as "single use" or "Restricted use" Use novelty items whenever possible (for example, cake toppers that have been used once). Tag them. Replace them frequently.

- Temperature awareness: Never expose printed items to temperatures that exceed the filament temperature rating or the epoxy coating temperature rating.

Inherent Limitations: Managing Expectations

Honesty is crucial:

- Sterility ≠ food safety: Enabling sterile 3D printed parts for medical applications is very different from, and impossible to achieve, standard FFF printing of kitchen items. The focus is on minimizing the risk of contamination.

- longevity: These prints will degrade. Over time, exposure to the elements (UV, food chemicals, wash cycles) can compromise integrity. Replace items regularly, especially if they are worn, discolored, smelly, or cloudy.

- responsibility: Using DIY 3D printing for commercial food contact poses significant liability risks due to the challenges of ensuring batch safety.

Conclusion: Proceed with caution

Using 3D printing to create functional items for food contact is possible, but requires a lot of effort, specialized materials and careful processing. Prioritize Certified natural/white PLA or PETG from a reputable supplier with a record of FDA compliance. invest in one stainless steel nozzleadhere to strict health protocols When printing, seal the print carefully Certified food safe epoxy resin.

It is crucial to understand and accept significant limitations: Bacteria can easily grow when not sealed, have relatively low heat resistance compared to manufactured plastics, degrade common food substances, and are inherently difficult to clean. Keep print items Low risk, short time, low temperature food contactconsider them as non-permanent solutions. Novelty items such as cake toppers carry very little risk; reusable utensils inherently carry a greater risk.

For applications where failure or contamination could have serious consequences (professional kitchens, strict hygiene environments, pharmaceutical prototypes), It is highly recommended to explore alternative manufacturing methods such as professional injection molding using USP Class VI plastics or food grade metal casting/CNC machining. Companies like GreatLight excel in precisely regulated environments, utilizing advanced methods such as SLM metal printing and precision CNC machining to produce parts where absolute material integrity and surface finish hygiene are critical, often with surface treatments such as electropolishing for final cleanliness.

The goal is not to prevent innovation, but to empower it with knowledge and ensure that creations put safety alongside beauty and functionality.

FAQ: Food Safety 3D Printing Supplies

1. Can I buy whatever I want? "Food SafetyPLA" And print a mug?

No. "Food SafetyPLA" Usually refers to GRAS base resin only. Crucially, dyes/additives in colored PLA are rarely certified. Additionally, even certified filaments printed on FFF printers have porosities, and no It is safe for liquids without thorough epoxy sealing and knowing the limits (no hot liquids, reduce acidic drinks, check/replace frequently).

2. Is PETG necessarily food safe?

not necessarily. Although PET resin is FDA-approved for use in food containers, glycol-modified (G) and especially colorants Added to the filament determines safety. Only use PETG filaments that are explicitly certified by the FDA and comply with FDA standards including its dye. Natural/colorless certified PETG is the safest, but less common.

3. Can I put sealed PLA/PETG printed items in the dishwasher?

Only if the specific food-safe epoxy coating you use explicitly meets dishwasher-safe standards. Most certified epoxies are no Dishwasher safe. Check the manufacturer’s data sheet. Washing hands with warm soapy water is not enough