Navigating food safety in 3D printing: The basic role of sealants

3D printing has revolutionized prototyping and manufacturing, thus allowing the entire industry to have complex designs and rapid production. But as creators venture into applications involving food contact – custom cookie cutters, unique beverage software, kitchen tools or custom cutlery – a crucial challenge emerges: Ensure food safety. Original materials (PLA, PETG, nylon, resin, and even metal), original 3D printed parts are usually Insecure Direct, repeated food contacts are contacted directly from the build plate. Savior? Food safety sealant.

Nude 3D does not print food safe?

- Micropores and layered lines: A layer of 3D printing creates microscopic gaps, gaps and ridges on the surface. These tiny blemishes become an ideal breeding ground for bacteria, molds and yeasts that cannot be completely cleaned and cleaned.

- Material composition and leaching: Many common 3D printing materials contain additives (plasticizers, colorants, stabilizers), residues in production, and even potentially harmful harmful monomers (especially in resins) that can be immersed in food or beverages. Even if the basic polymer is theoretically food grade (such as certain PLA), this processing involves non-food-safe lubricants, pigments, or catalysts.

- Thermal and chemical fragility: When exposed to hydrothermal, acidic foods (such as tomatoes or citrus), oils, or repeated washing of dishes, some materials degrade, twist or leach more chemicals.

Food Safety Sealants: Creating Protective Barriers

Food safety sealants are specially designed and tested coatings that are non-toxic when in contact with food. They work by forming smooth, non-porous and chemically resistant barrier layers on the rough, porous surfaces of 3D printing. This obstacle:

- Prevent bacteria from carrying: Seale the microscopic pores and layered lines to form surfaces that can be thoroughly cleaned and disinfected.

- Leaching block: Act as a protective cover to prevent any potentially harmful substances within the 3D printed section from moving into the food.

- Improve durability: It can increase resistance to wear, moisture, chemicals (acids, oils) and heat, thus extending the life of printed items.

- Provides a smooth finish: Improve aesthetics and make parts more pleasant and practical.

Types of food safety sealant: Choose the right shield

Not all paints are equal. Key considerations include the intended use (refrigeration, hydrothermal, dishwasher safety), durability needs and ease of application. This is the common type:

-

Epoxy resin: special FDA-compliant food grade epoxy resin It is the best choice.

- advantage: Create a hard, crystalline, highly durable, and very smooth chemical resistance barrier. Ideal for items that require high wear or liquid curb (cup, bowl). Many are dishwasher-safe.

- shortcoming: Need to mix (resin + hard). Possibly toxic smoke during application requires excellent ventilation. Careful treatment is required.

-

Polyurethane coating: Specifically FDA certified food safety polyurethane.

- advantage: Can be used in water-based formulations (easier/safeer applications) and solvent-based formulations (usually more durable). Provides good scratch and chemical resistance. The water-based option has low VOC.

- shortcoming: Water-based may not be as durable or heat-resistant as epoxy resins. Solvent-based ventilation is required.

-

Silicone coating: Food grade silicone (usually RTV type).

- advantage: Flexible, excellent chemical and temperature resistance (suitable for oven gloves, flexible molds), essentially non-stick properties. Usually non-toxic and easy to apply.

- shortcoming: Possibly visible texture (slightly rubbery feel/touch). The durability of wear resistance may be lower than that of epoxy. Specialized in finding platinum solid silicon silicon for food contact.

- Food contact surface spray/paint: Performance-based or FDA-compliant spray sealant.

- advantage: Easy to apply by spray. Thin or even coatings can be achieved. Suitable for hard-to-reach areas.

- shortcoming: Each volume may be more expensive. Achieving always thick, flawless obstacles requires skill. Durability may not match epoxy or polyurethane.

The key importance of certification: Finding compliance

Unless by Certification. Looking for proof of compliance. The most recognized standard is U.S. Food and Drug Administration (FDA)especially below 21 CFR 175.300 for indirect food additives (coatings). Reputable sealant manufacturers will specify FDA compliance (list specific regulations) and provide documentation regularly. EC 1935/2004 is a related EU framework. Never assume "Non-toxic" Labels equal food contact safety.

Best Practices for Applying Food Safety Sealants: A Step-by-Step Guide

Proper application of sealant is essential for safety and longevity:

- Start with basic food safety materials: Where available, select filaments, resins or metal powders specifically marked as food safe or FDA compliant. This minimizes risk In the back Sealant.

- Thorough cleaning: Remove all support materials and wash carefully. For plastic, use a warm soapy water and a soft brush to ensure that all debris is removed (especially from the layer line). Rinse thoroughly. For resin, first follow the manufacturer’s fixing instructions. Completely dry.

- Sand and smooth: Gentle sanding (such as 400-800 sandpaper) reduces obvious layer lines without compromising the accuracy of the dimensions. Wipe off all dust (if safe material is safe, then thoroughly air dry).

- Prepare sealant: Follow the manufacturer’s instructions preciselyespecially for epoxy oxidation mix ratio and pot life. Prepare a clean and ventilated workspace (use a respirator if dealing with solvent/isocyanate).

- application:

- Dip/brush: Submerge or use high-quality brushes for smooth application. Avoid bubbles. Multiple thin layers are much better than a thick coat. Apply the first layer thinly to ensure good adhesion.

- spray: Apply to a thin coat from the recommended distance. Avoid running and sagging. Multi-layer coats are essential.

- Rotate or reposition the parts for even coverage without merging.

- Maintenance: This is not negotiable. cure Exactly As specified by the sealant manufacturer – comply with time, temperature, humidity and ventilation requirements. Hurry healing can impair safety and performance. Epoxy resins and polyurethanes usually require several days at room temperature. Silicone heals quickly. The ultimate food safety performance may require heating.

- Final cleaning and drying: After being completely cured, thoroughly clean the sealed portion with gentle soap and water to remove any potential surface residue. Completely dry.

Important considerations and limitations

- Durability: Sealant can be broken or worn, especially in sharp corners or overhead areas. Check items regularly.

- Thermal Limits: Very few sealants are microwave ovens or The oven is safe. Verify a specific safe temperature range. Avoid dishwasher unless it is clearly stated that it is safe for sealants (usually only high epoxides).

- Material Compatibility: First test the sealant on small areas to ensure it adheres correctly and does not twist or damage the basic material.

- Careful for single use: Sealing is often used for rigid objects used with cold or room temperature food/beverage. Avoid using sealed parts as hot liquids or acidic foods unless the sealant is explicitly rated. Do no Sealed porous items are used for repeated cooking/cutting (such as molds or cutting boards) – Sealing will inevitably reduce and risk contamination.

Conclusion: Determine the security of custom creations

The world of custom 3D printed food contact items is exciting, but safety must be the first. When carefully selected to fit and carefully applied, food safety sealants provide an essential solution by creating a safe, practical and durable surface. It bridges the gap between amazing design and practical, non-toxic usability. Choosing compliant materials from reputable suppliers and strictly complying with application protocols ensures that your innovations are not only beautiful but are manufactured responsibly for their intended purposes.

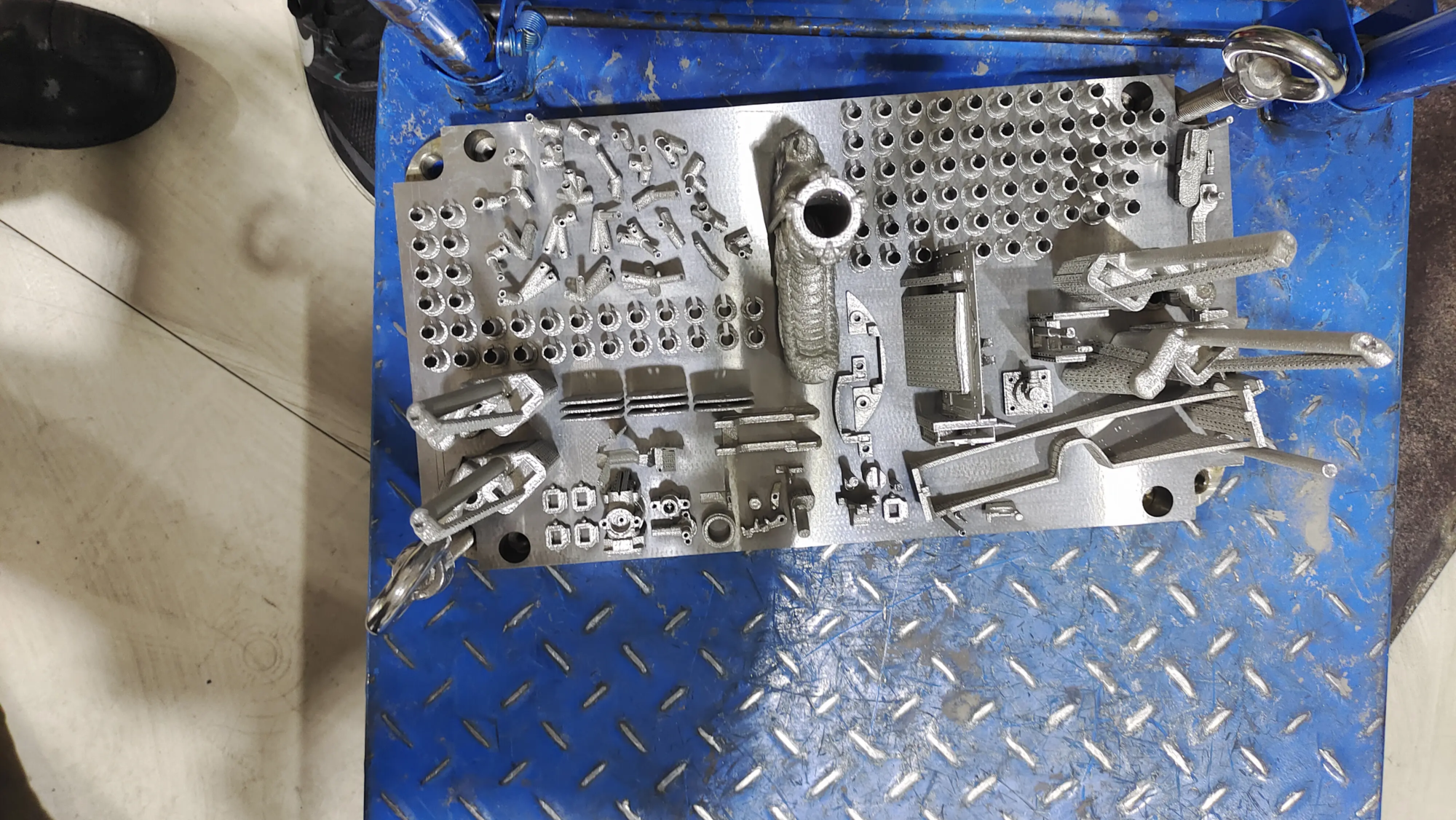

At Greatlight, as a professional rapid prototyping manufacturer based on advanced SLM printers and comprehensive production technologies, we understand the critical importance of functional integrity and security. Whether you use metals or premium polymers, we don’t just offer parts. Our One-stop post-processing and completion expertise When applicable, extend to applications with durable, compatible food-safe finishes. We use certified materials and processes to help browse these complex requirements, ensuring your functional food contact prototypes seamlessly from concept to safe reality. Choosing Greatlight means working with teams dedicated to precise, secure and delivering tailored fast prototype solutions that meet the highest standards.

FAQ: Food Safety 3D Printing Sealant

Q1: If I only use it, I can skip the sealant "Food Safety" PLA?

A1: No. While some plants come from food grade ingredients, the final printed part is not food safety. The printing process introduces porosity, and the layered lines are ideal for bacteria, as well as potential contamination from printer nozzles, build boards, or the environment. Sealants are essential for any functional food contact except for disposable decorative items.

Question 2: Is there a true “food-safe” sealant DIY solution?

A2: Very alert to DIY mixtures (e.g. use mineral oil, coconut oil, craft store "Sealant," or thinning conventional epoxy resin). These are unregulated and food contact safety is not tested. They can be toxic, migrate into food, fail to seal adequately, dissolve or encourage microbial growth. Only use sealants to rated and certified food-contact surfaces through relevant authorities (such as 21 CFR 175.300) and other relevant authorities.

Question 3: How many layers of sealant do I need?

A3: Generally, it is recommended to use 2-3 thin coats. A thick coat is prone to running, sagging, uneven curing, and an increased risk of failure due to internal pressure. Thin coat ensures penetration of pores, better adhesion and a more durable bubble-free finish. Always follow specific coat recommendations for sealant products to be used.

Question 4: Can I safely make a food-safe 3D printed item dishwasher?

A4: This is very challenging. Standard PLA prints will melt in the dishwasher. Even high temperature materials, used in combination with sealant, face conditions (detergent, high heat/pressure, wear). The only one Specific high-temperature food grade epoxides should also be considered, after thorough treatment, rigorously tested and clearly sold as dishwasher safe, and should even be considered, even if that is limited. It is highly recommended to have a long life and safety of the hand wash. Carefully verify any dishwasher safety claims.

Q5: Is the food safety sealant microwave oven safe?

A5: Usually, no. Most epoxy resins and polyurethanes decompose or leaching chemicals when heated. And some special high temperature sealants possible Existence, microwave 3D printed sealed items are strongly dissuaded and Instructions are provided. Microwaves cause heating and extreme heat spikes that most paints cannot reliably withstand.

Question 6: How long does it take to reapply sealant?

A6: There is no fixed schedule; it depends on usage, sealant type, wear and cleaning. Check regularly. The signs you need to reapply include: fading/loss, visible scratches or scratches in the paint (especially in areas that touch food/beverage), cloudy or rough feeling. If any violation occurs in the coating, the part is no longer applied to food contact until it is resealed and fully secured.

Question 7: Can Greatlight apply food safety coatings to 3D printed metal parts?

A7: Absolute. Although metal parts (especially printed using our advanced SLM technology) are often smoother than plastic parts, seals are recommended for food applications to ensure absolute safety and enhance cleanability. Our aftertreatment services include surface smoothing (such as polishing) as well as FDA-compliant food-grade sealants that are suitable for metal surfaces. We ensure compatibility and correct application tailored to your specific metal types (stainless steel, aluminum alloy, titanium, etc.). This provides the highest level of safety and functionality for customized metal food handling components.