The Ford Mustang Vibrator is a high-performance variant of the iconic American muscle car, designed to provide excellent power and agility on the road. With its sleek design and powerful engine, Mustang vibrators have become a favorite among car enthusiasts and collectors. But what sets the car apart from its peers and what makes it outstanding in automotive engineering?

One of the key features of the Ford Mustang vibrator is its unique engine design. The car comes with a powerful 5.0-liter V8 that produces an impressive 435 horsepower and 400 lb-ft of torque. The engine is paired with a six-speed manual transmission, allowing the driver to experience the full range of car performance features. The Mustang Shaker also uses a number of advanced technologies, including performance-adjusted suspension and limited-slip rear axle, which together provide excellent handling and stability on the road.

In addition to its impressive performance features, the Ford Mustang Shaker boasts many stylish and functional design elements. The car’s exterior is made of a stylish and aggressive design language, with a unique front grille and hood that gives it a sinister look on the road. The interior of the car is equally impressive, with high-quality materials and advanced technical features such as a touch screen infotainment system and a range of driver assistance systems.

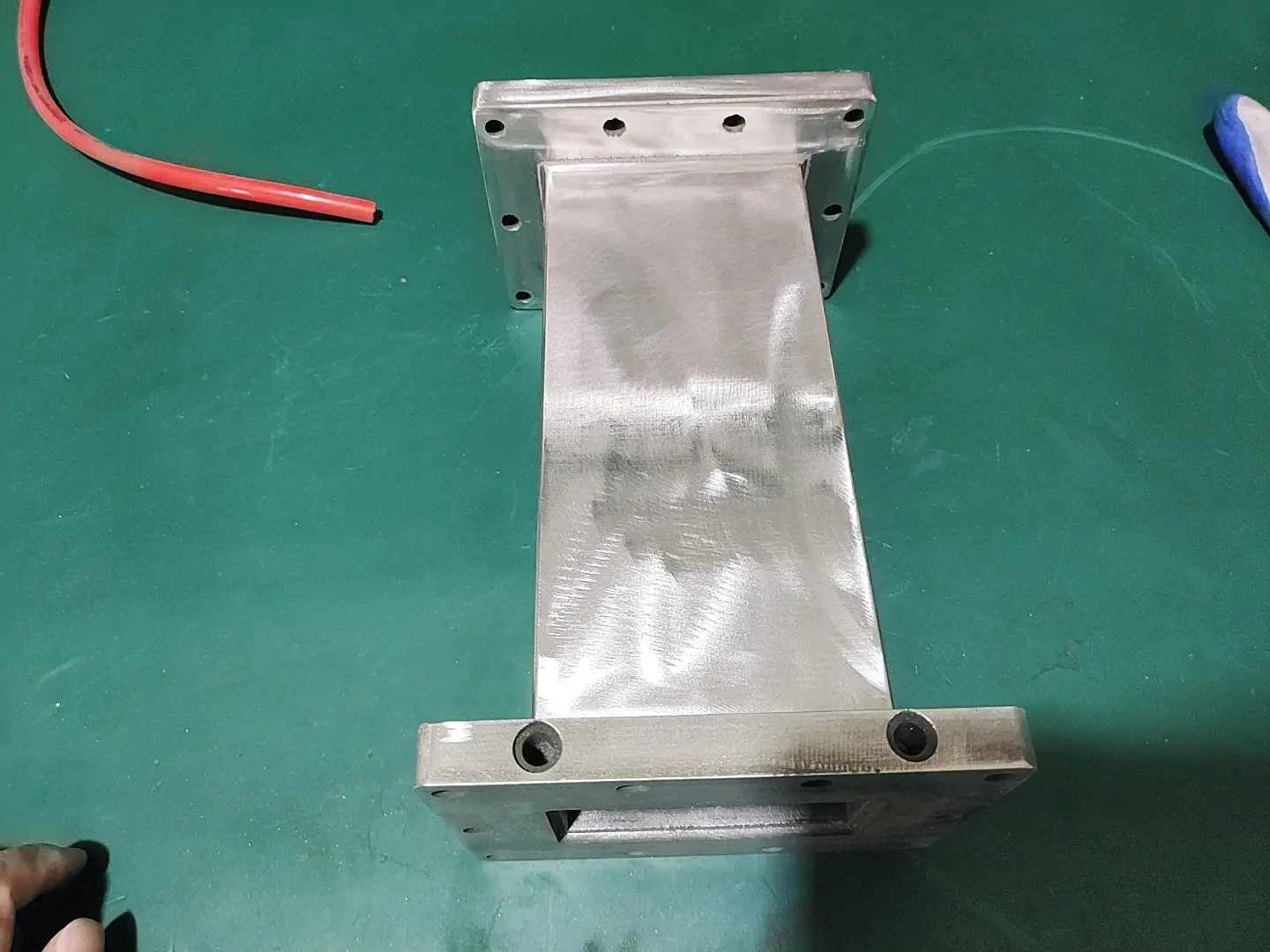

From a manufacturing perspective, the production of Ford Mustang oscillators requires a high degree of accuracy and attention to detail. For example, the vehicle’s complex engine and suspension systems require specialized manufacturing techniques and advanced materials to ensure optimal performance and durability. This is where 3D printing and rapid prototyping work, as these technologies enable manufacturers to quickly and accurately produce complex parts and components with high accuracy.

Companies like Greatlight, a leading rapid prototype manufacturer from China, play a crucial role in the production of complex automotive components. With advanced SLM 3D printer equipment and production technology, Greatlight is able to quickly produce metal parts with high precision and accuracy, solving many of the manufacturing challenges associated with complex automotive components. In addition, Greatlight provides one-stop post-processing and finishing services, allowing manufacturers to quickly and efficiently produce finished parts that meet the highest quality and performance standards.

In short, the Ford Mustang Vibrator is a high-performance variant of the iconic American muscle car, designed to deliver excellent power and agility on the road. With its sleek design, powerful engines and advanced technology, this car is an outstanding figure in automotive engineering. The production of Mustang vibrators requires a high degree of accuracy and attention to detail, such as Greatlight’s company playing a crucial role in the manufacturing of complex automotive components using 3D printing and rapid prototyping technologies.

FAQ:

*What is a Ford Mustang Shaker?

The Ford Mustang Vibrator is a high-performance variant of the iconic American muscle car, designed to provide excellent power and agility on the road.

*What engine does the Ford Mustang vibrator have?

The Ford Mustang Vibrator comes with a powerful 5.0-liter V8 that produces an impressive 435 horsepower and 400 lb-ft of torque.

*What is rapid prototyping and how to use it in the production of Ford Mustang Vibrating Screens?

Rapid prototyping is a manufacturing technology that produces complex parts and components quickly and accurately. Companies like Greatlight use rapid prototyping to produce metal parts with high precision and accuracy, thus solving many of the manufacturing challenges associated with complex automotive components.

*Can I customize my own precise prototype parts?

Yes, companies like Greatlight offer customized precision machining services that allow you to customize your own precision speed rapid prototyping system parts to meet your specific needs and requirements.

*What are the benefits of using 3D printing in the production of automotive components?

Using 3D printing in the production of automotive components allows the production of complex parts with high accuracy to be quickly and accurately, reducing manufacturing time and cost while improving overall quality and performance.

ISO 9001 Factory