Whoever can overcome Tuozhu is always Takuba himself.

On March 25, 2025, Tuozhu officially published a new office level of office level four in one – H2D. As a multifunctional platform incorporating 3D printing, laser engraving, cutting and brushing, H2D redefines the limits of personal intelligent manufacturing.

As Takutake promised last year:

“We create a device that never compromises and can unravel the limits of the imagination of consumers’ 3D printing.”

Today, H2D is there.

In fact, this is not the first time that we have heard of H2D. From the end of last year, only one page of a product suspected of being “disclosed” fled quietly in the industry. The information disclosed at this time included: the new machine was named H2D, adopting a double spray head structure, and can be paired with the Multi-Coulers 2 PRO power supply system.

Now it seems that these rumors are not only true, but are almost exactly consistent with the officially published configuration. However, no one expected it to be a four -one multifunction device. Obviously, the outside world has always underestimated that Tuozhu, which has been silent for a year, would again inspire industry with such complete equipment.

From the start of the printing, Tuozhu H2D showed remarkable strength.

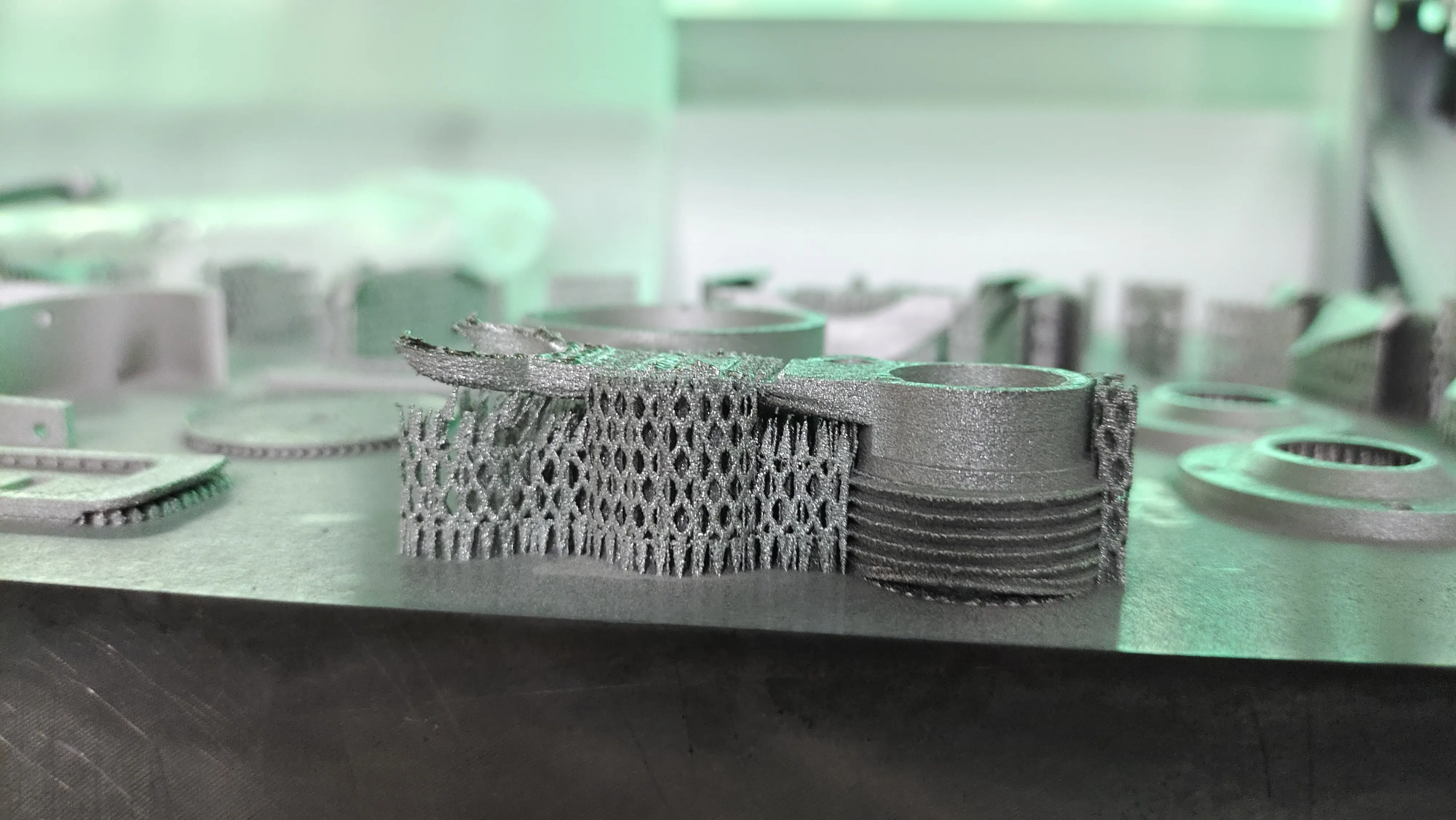

H2D has an ultra-large printing volume of 350 × 320 × 325 mm, which is capable of producing larger models. Its printing speed can reach up to 1000 mm / s, and it can be stable in an approximately 600 mm / s during real continuous printing, both at high speed and stability.

H2D is equipped with a double spray head system, which can treat several metallic materials at the same time, by making the combined printing of soft and hard materials, or using a single spray head to print support materials to improve the accuracy and surface quality of the complex models. Compared to the traditional material change method, double nozzles can also reduce the waste of multicolored printing materials and save time.

H2D is associated with a new generation of intelligent power systems – AMS 2 Pro, which has achieved other upgrades in material management. This system not only continues the basic advantages of the first generation AMS in terms of online drying, storage and integration of the power supply, but also adds an active drying function to the Pro version. Its internal energy can be automatically exhausted and supports a rotary drying mechanism to keep the wires in optimal condition while heating evenly.

AMS 2 PRO supports drying at constant temperature up to 65 ° C, meeting the drying needs of most materials. For highly hygroscopic consumables such as nylon, TPU and strengthening carbon fibers, users can choose AMS HT to reach a drying temperature up to 85 ° C, effectively improving the stability of materials and the printing success rate.

In addition, the H2D is equipped with an active temperature heating of 65 ° C and a hot end at high temperature up to 350 ° C, which can effectively remove the deformation and deformation of high performance materials during printing, improve intercouche adhesion and give a complete game to the performance of the material. Its system is compatible with high -performance consumables such as reinforced composite materials in carbon fiber and fiberglass, widening a wider space for industrial quality applications.

I must say that Tuozhu is indeed excellent in intelligent detection. H2D incorporates a view camera, a lidar, a nozzle camera, etc., and combines computer vision algorithms to identify the arrangement of materials, optimization of the path and intelligent monitoring throughout the process, effectively reducing material waste and overall improving the quality of printing and the effectiveness of resource use.

Finally, in terms of printing precision, H2D has created a killer weapon: the introduction of a visual coding system to reach a precision of motion up to 50 μm. Combined with the Self-Developed PMSM Servo-extrusion engine of Tuozhu, the accuracy of the assembly of printing parts has been improved by a sauce approach.

Then, the culmination of the real “new species” of H2D will appear: the laser module.

In addition to its powerful 3D printing function, H2D also has laser engraving and laser cutting capacities. Its modular design supports the installation of blue light lasers 10W and 40W 455 Nm, which can reach an effective plywood and 15 mm thick, respectively. In terms of user experience, H2D supports calibration and automatic layout and can also be equipped with a smoke and dust purifier to ensure practical operation and interior air safety.

Not only is H2D also equipped with a rotary module which supports the curved surface treatment of structures such as cylinders and rings, so that treatment objects are no longer limited to planar materials. At the same time, the laser module also incorporates an air -assisted cooling system to provide more stable control of the air flow during laser treatment, thus improving the quality of the cut and the surface precision.

In addition to printing and engraving, H2D also supports cutting and brush functions, not surprising that it is called a personal manufacturing center that manages the entire process. However, we have not really tested this part of the functions today. After obtaining the actual assessment of the machine, we will bring you a more detailed practical experience.

After the introduction above, I believe that you are already very moved by this “versatile peripheral four in one”. However, according to what we have learned, H2D is currently out of stock on several electronic commercial platforms, which shows that its popularity of the market is so high that it still has to be quick to buy.

In order to facilitate everyone to choose and compare, we have compiled the official prices of different versions as follows:

H2D autonomous version: 11,999 ¥

H2D set: 13 999 ¥

H2D laser set (10W): 17,999 ¥

H2D laser set (40W): 22,999 ¥

Currently, after taking advantage of the national subsidy policy, the above price can be reduced to ¥ 2,000. We will continue to update the departure experience and the real test performance of H2D in subsequent criticisms more, so stay listening!