The Power of Accuracy: How 3D Printing Uses Gear Trouble Changes Stress Relieving

In an age of ongoing digital stimulation, finding tangible tools to manage stress and improve focus is more valuable than ever. enter Gear Troubles: 3D Printing and Calmness– Well-designed equipment combines haptic therapy with cutting-edge manufacturing. Unlike mass-produced plastic toys, this type of gear-based irritation 3D printing technology Transform simple concepts into personalized health tools. At Greatlight, we use our expertise in industrial-grade additive manufacturing to redefine possibilities in rapid prototyping, providing not only parts but also performance-oriented solutions.

Furious science

Research in behavioral psychology has always shown that irritability can reduce anxiety, increase concentration, and even improve memory retention. The repetitive movement of manipulating objects (such as rotating gears) engages with the sensory cortex of the brain to form a "White noise" Effects of calm mind. For neurodiverse people, students or professionals in high-stress environments, well-designed irritability tools are not distractions, but rather a cognitive help.

Gear troubles: Design fits dynamic

Our equipment worries are not just another trinket. Its interlocking gear system rotates smoothly around the central axis, providing satisfactory tactile feedback with minimal force. Magic lies in its accuracy:

- Complex geometric shapes: Asymmetric tooth design prevents interference.

- Ergonomic Forms: The curved edges are comfortable to fit in the palm or pocket.

- Material versatility: Printed in the form of stainless steel, titanium or medical grade polymer for durability.

Unlike alternatives to injection volumes, 3D printing allows fine-tuning of tolerance (down to ±0.05mm) to ensure seamless rotation – a key factor for caution in an office or classroom.

Why 3D printing? Great Advantages

The struggle between traditional manufacturing and equipment troubles. Subtle design flaws, such as friction points or unbalanced weights, can ruin the user experience. exist Greatwe solved the following aspects:

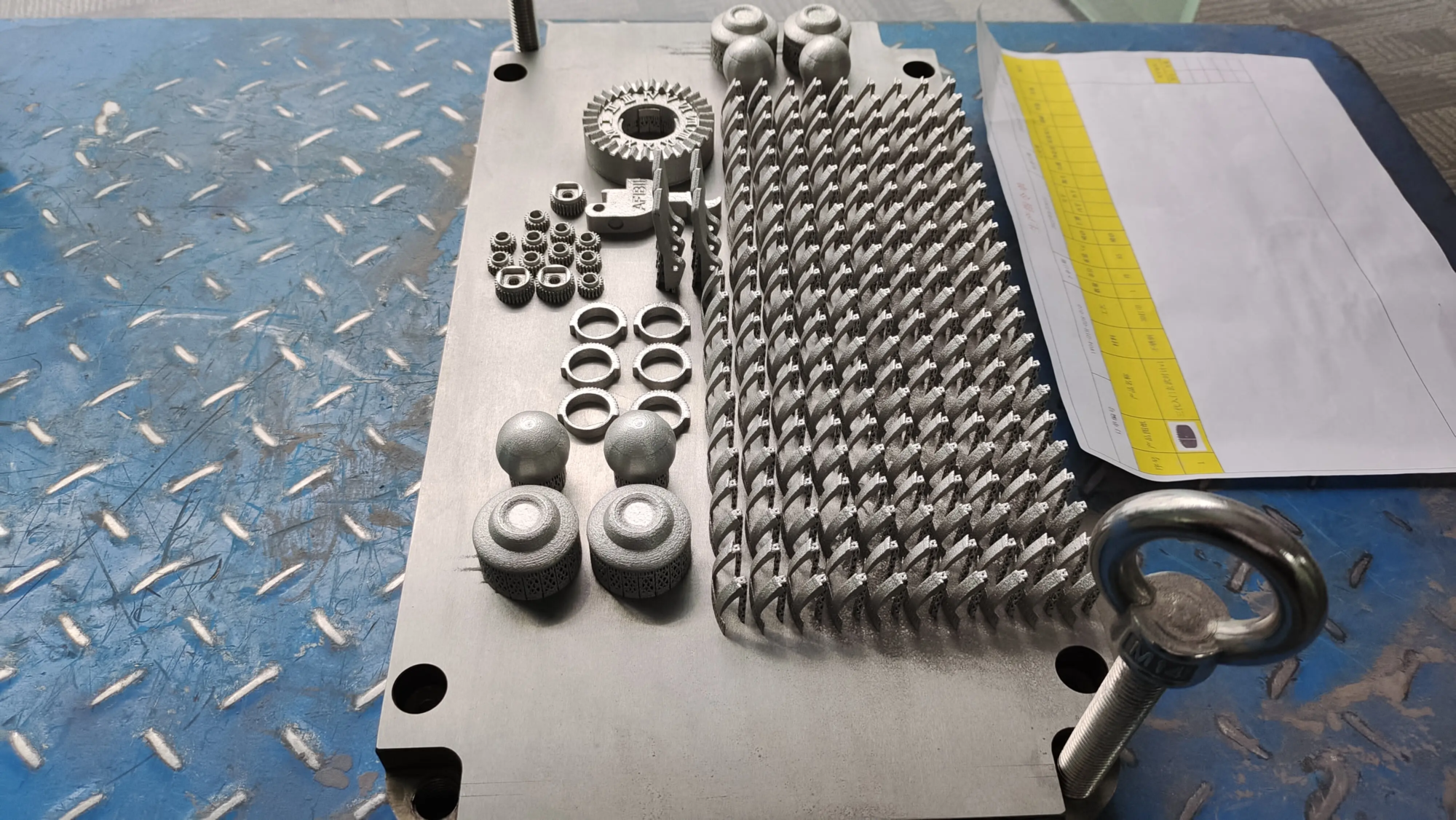

- Industrial SLM (Selective Laser Melting) Printer: Create layered metal parts with internal lattice structure to optimize weight and strength.

- AI-driven prototyping: Our software simulates the stress distribution of trans-gear teeth, thus achieving pre-printing refinement.

- One-stop post-processing: Used for aesthetic and hygienic bead blasting, powder coating or antimicrobial seal.

- Fast Market: Functional prototype within 48 hours; full production within 2 weeks.

This ability makes us Top Quick Prototyping Partners In the aerospace, medical and consumer sectors, especially for projects that require precise accuracy.

Customization: Your Troubles, Rules

A true superpower of 3D printing? Personalized. Greatlight customers have adjusted all aspects of equipment:

- size: mini (keychain friendly) to xxl (desk display).

- Material: Hypoallergenic titanium used for sensitive skin, dark resin or recycled metals.

- brand: Art pattern filled with company logo or gear surface.

- Function: Add gyro elements or tension regulators.

We even used proprietary sintering techniques to prototype multicolor gradient irritation – providing creativity without limits.

Case Study: From CAD to Calm

A European ergonomics company recently ordered 500 customized equipment for therapists. Using CT scan data from the handle, we iterated the 3D model in nylon PA12, thereby reducing joint strains in arthritis patients. Post-treatment includes electronic coatings for chemical resistance – demonstrating how our end-to-end services solve niche challenges.

in conclusion

Gear Troubles: 3D printing and calm symbolize a new wave of functional health technologies, with engineering accuracy consistent with mental health. By leveraging the agility of metal 3D printing and the manufacturing capabilities of Greatlight, we are providing tools that are not only stress reliefers, but also conversation starters about innovation.

Whether you’re a startup testing irritable design or a corporate sourcing brand company gift, our team offers Certified quality Comply with ISO 13485 and ASTM standards at competitive prices.

Reimagine tranquility – one equipment at a time.

FAQ

Q: Can I print a fully functional metal gear into one?

Answer: Absolute. With SLM printing, we can create monolithic gear assembly with moving parts without welding. The self-lubricating design ensures years of smooth rotation.

Q: What is the skin-safe material?

Answer: Ti6al4v titanium. Biocompatible, lightweight and perfect for sensitive users. We also provide hypoallergenic coatings upon request.

Q: How many design iterations are available for prototyping?

Answer: Unlimited. Our digital workflows can be revised up to 15 revisions in a week at the lowest cost (cost), which is the main benefit of additive manufacturing.

Q: Can environmentally friendly materials be used?

A: Yes. Recycled stainless steel and plant resins reduce environmental impact without compromising durability.

Q: Which batch sizes can be equipped?

A: From 1 prototype to 50,000 units. We use distributed 3D printing hubs in Asia and Europe to scale production.

Q: How to start customizing equipment troubles?

A: Upload your CAD file or sketch 📄 By Greatlight.cn. Our engineers will provide DFM analysis and quotes within 4 hours.

Transform your vision into tactile reality – related to the tranquility of today’s precisely designed. 🌟