Genesis 3D: Pushing the limits of printing – unleashing innovation with advanced SLM metal prototyping

The relentless pursuit of innovation requires tools that push boundaries. In the dynamic world of engineering, design, and manufacturing, rapid prototyping is not only helpful; This is indispensable. It bridges the gap between concept and reality, quickly and efficiently transforming virtual designs into tangible components. Among the technologies enabling this revolution, Selective Laser Melting (SLM)a premier metal additive manufacturing technology that stands out. At the forefront of leveraging this technology to empower businesses around the world are huge lighta premier rapid prototyping manufacturer dedicated to helping you Print beyond the limits.

For engineers grappling with complex geometries, designers craving unfettered freedom, or product managers racing against time, traditional machining often hits a brick wall. Imagine the need for a complex aerospace stent with internal cooling channels, an ultra-lightweight biomedical implant shaped perfectly to fit the patient’s anatomy, or a rugged automotive part designed for optimal heat dissipation. For such complex structures, traditional methods such as CNC machining or casting can be expensive, slow, and sometimes impossible. This is where Genesis 3D comes into play.

Genesis 3D: The power of SLM technology

GreatLight’s Genesis 3D functionality is built around State-of-the-art selective laser melting. But what makes SLM so transformative for metal prototyping?

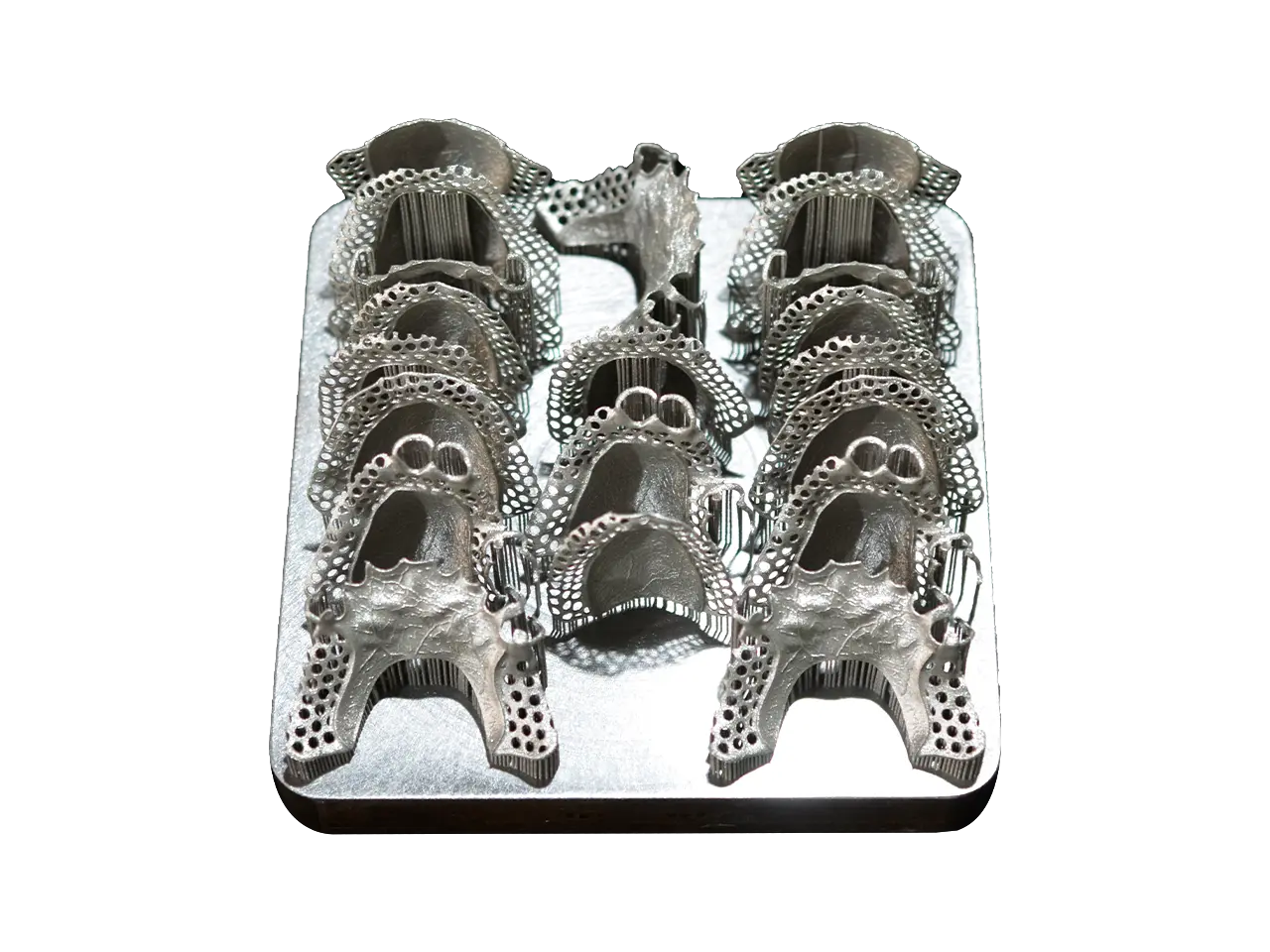

- Unparalleled freedom from complexity: SLM uses high-power lasers to selectively fuse fine metal powder particles to build parts layer by layer directly from CAD data. This allows for the creation of internal lattices, channels, undercuts and organic shapes that are simply not possible with subtractive techniques.

- Real functional metal parts: Unlike many polymer 3D printing methods, SLM produces parts using high-performance metals such as stainless steel (316L, 304), titanium alloys (Ti6Al4V), aluminum alloys (AlSi10Mg, Scalmalloy), nickel alloys (Inconel 625, 718), and cobalt-chromium alloys. The mechanical properties (strength, stiffness, fatigue resistance) of these parts rival and sometimes exceed those of their conventionally manufactured counterparts.

- Speed up iteration: "quickly" Crucial in prototyping. Genesis 3D significantly shortens development cycles. Design modifications are digitally incorporated and printed on demand, allowing for faster testing, validation and improvement. Tasks that would take weeks to complete through traditional routes can often be completed in a matter of days.

- Material efficiency and lightweighting: SLM is additive, meaning it uses only the materials needed for the part itself and minimal support structures. This significantly reduces waste compared to solid block machining. Combined with the optimized geometries enabled by SLM, parts can be significantly lighter while maintaining strength – critical in industries such as aerospace and automotive.

- merge: Complex assemblies containing multiple traditionally manufactured parts can often be redesigned and printed as a single, solid Genesis 3D component, reducing assembly points, potential failure points and overall complexity.

Beyond the printing layer: excellence from a single source

GreatLight understands that printing is only one step in getting your parts to market. True service excellence lies in comprehensive solutions. That’s why Genesis 3D is part of the whole One-stop service envelope Make sure your prototype not only prints, but is complete and ready for its intended application:

- Design for Additive Manufacturing (DfAM) supports: Our engineers work closely with you to optimize your design specifically for the SLM process. We identify potential issues, propose topology optimization strategies, ensure manufacturability, and maximize the benefits of Genesis 3D—whether it’s lightweighting, fluid dynamics improvements, or integration.

- Materials expertise: We don’t just provide a standard list. We will consult you on your choice best Metal alloys that meet the mechanical, thermal, corrosion resistance or biocompatibility requirements of your application. Most materials can be customized.

- Precision post-processing: The original SLM part requires finishing. GreatLight specializes in providing integrated post-processing services:

- Support removal: Necessary build supports were carefully removed without damaging the delicate geometry.

- Stress Relief and Heat Treatment: It is crucial to achieve the desired microstructure and eliminate the internal stress generated during the printing process.

- Surface enhancement: Techniques such as shot peening, abrasive flow machining, vibration finishing or polishing can improve roughness, fatigue life and aesthetics.

- Processing accuracy: For features that require tight tolerances (±0.025mm achievable) or specific mating surfaces, we have integrated CNC machining capabilities.

- Non-destructive testing (NDT): Options include X-ray inspection for internal defect detection or dye penetrant inspection for surface cracks.

- coating: Specialized coatings are applied as needed for wear resistance, corrosion protection or biocompatibility.

- Customization and flexibility: Need a unique alloy blend? Need expedited shipping? Have complex finishing requirements? Our scalable operations and extensive manufacturing capabilities allow us to quickly and efficiently customize solutions to your exact specifications.

Why work with Gretel? Your trusted authority on rapid prototyping

Choosing the right prototyping partner is crucial. as One of the leading rapid prototyping companies in ChinaGreatLight stands out through its unwavering commitment to EAT:

- Expertise: Deep specialization in metal additive manufacturing (especially SLM), supported by our fleet of advanced SLM equipment and experienced metallurgical engineers. We understand the science behind printing and post-processing.

- authority: We have a strong track record over the years of successfully delivering complex, high-risk projects in diverse industries including aerospace, defence, medical devices, automotive motorsport, energy and industrial equipment.

- Credibility: Strict quality control protocols embedded throughout the entire process chain, transparency in communication, compliance with deadlines and consistent delivery of functionally sound parts build trust. We are your innovation partner, not just a supplier.

Accelerate your innovation journey

Genesis 3D is not just for prototyping; This is about unlocking new possibilities in design and manufacturing. It enables breakthrough innovation by removing historical constraints. Whether you are pushing the limits of performance in aerospace, developing life-changing medical implants, optimizing next-generation automotive systems, or building high-value industrial tools, Genesis 3D technology with GreatLight gives you the freedom and speed you need.

Conclusion: Unlimited potential, realized

The ability to quickly transform complex digital designs into durable, high-performance metal parts is revolutionizing product development. Genesis 3D is powered by GreatLight’s advanced SLM technology and comprehensive one-stop service, giving you unprecedented freedom Print beyond the limits. We transcend traditional manufacturing constraints to achieve complexity, accelerate time to market, enhance functionality and improve material efficiency.

Don’t let limitations block your vision. Embrace the future of rapid prototyping with a partner known for expertise, quality and service. Let GreatLight help you push the boundaries and bring your most ambitious designs to life.

Customize your precision rapid prototyping metal parts today – fast, reliable and competitively priced! [Call to Action Link – e.g., Request Quote Today!]

FAQ: Genesis 3D Printing Services (SLM Metal Prototyping)

Q1: How is Honglaite’s SLM (Genesis 3D) different from other metal 3D printing services?

A: GreatLight combines cutting-edge SLM equipment with deep metallurgical expertise and comprehensive, integrated post-processing. Our one-stop approach ensures seamless production from optimized design to finished functional parts. The emphasis on DfAM consulting and our ability to handle highly complex geometries and stringent industry requirements sets us apart.

Q2: Compared with CNC machining, what design advantages does Genesis 3D/SLM have?

A: SLM excels at creating complex internal features (cooling channels, lattice structures), highly complex organic geometries, lightweight structures, and integrated components that cannot be machined. Design changes are also faster to implement and often cheaper.

Q3: Can SLM parts achieve the same strength as machined parts?

Answer: Yes. Properly machined SLM parts using the right materials can achieve mechanical properties similar to, and in some cases exceeding, cast or forged parts. Post-processing such as heat treatment is critical for optimal strength and durability.

Q4: What metals can GreatLight typically 3D print with Genesis?

A: We specialize in a variety of materials: stainless steel (316L, 304, 17-4PH), titanium alloys (Ti6Al4V), aluminum alloys (AlSi10Mg, Scalmalloy), nickel-based superalloys (Inconel 625, Inconel 718) and cobalt-chromium alloys. Custom alloy requests will be evaluated on a case-by-case basis.

Question 5: What level of detail and accuracy can I expect?

A: SLM can achieve feature resolution down to approximately 100 microns. Post-processing precision machining allows us to meet tight tolerances (±0.025mm or better) on critical surfaces as needed. Minimum wall thickness depends on geometry but can be very thin.

Question 6: What post-processing services are required for SLM parts?

A: All SLM parts require support removal and often require stress relief or heat treatment. Additional services such as CNC machining, surface finishing (polishing, grinding), shot blasting, inspection or coating are applied depending on the part function and requirements – this is the comprehensive service offered by GreatLight.

Question 7: How fast can GreatLight typically twist metal prototypes?

A: We prioritize speed. Simple prototypes can often be delivered within a few days. Complex parts with stringent requirements may take a few extra days, but we always outperform traditional manufacturing lead times. Expedited options available.

Question 8: Are Genesis 3D parts suitable for end-use applications or just for prototypes?

Answer: Of course! While ideal for rapid prototyping, SLM parts produced by GreatLight are commonly used as final production components in demanding applications such as aerospace, medical implants (post-certification), molding and performance automotive due to their strong mechanical properties.

Q9: How does Gretel ensure quality control?

A: We employ rigorous procedures: powder quality inspection, rigorous printer calibration, in-process monitoring, comprehensive post-processing quality assurance steps (dimensional inspection, visual, non-destructive testing methods as needed), strict material certification and traceability, and compliance with customer specifications and industry standards.

Q10: How to start GreatLight’s Genesis 3D project?

A: Just share your CAD files or concepts with us. Our expert engineers will conduct a prompt review, provide DfAM feedback, discuss material selection and finishing requirements, and provide a competitive quote. We simplify the process and get your project moving quickly. Contact us today!