Unlock Creativity: Your Final Guide to 3D Printing

The marble rolling rhythm slap, the tracks twist and turns satisfying clicks, is an elaborate running endless loop – Gravitrax fascinates the size of people. But what if your imagination goes beyond the box? What if you dream of custom launchers, unique track configurations, professional bases or brand new obstacles? This is where the incredible power of 3D printing transforms Gravitrax from a fantastic toy into an infinite engineering playground. This guide delves into the exciting world of Gravitrax 3D printing and provides expert tips to enhance your build, which is not credible.

Why use 3D printing for Gravitrax?

- Beyond the Box: Get rid of the limitations of standard sets. Design unique track curves with tighter curves, steep drippers or multiple exports that are not available for commercial use.

- Custom support and basics: Create custom installation solutions for complex multi-level settings, integrate tracks into complex dioramas, or use starter kits to build impossible large amounts of support structures.

- Professional accessories: Design custom marble launchers, unique catchers that trigger assist mechanisms, professional extensions, timing doors or art deco elements.

- Free experiment: The prototype new marble interactive concept is quick and affordable. Test a crazy idea without the commercial part.

- Repair and replacement: Print replacement of lost or broken parts (always respect the intellectual property of unique designs).

- Cost Efficiency: Despite the initial printer cost, printing many custom pieces is often cheaper than buying multiple extension sets for niche parts.

Key considerations for success in GRAVITRAX 3D printing: Deep diving

-

Master the materials (fiber focus):

- PLA: The undisputed gravity printing champion. It is affordable, has endless colors, is moderately harder, is easy to print, and has minimal warping. Ideal for most tracks, basics, decor and functional prototypes.

- PETG: Toughness, impact resistance and heat resistance to PLA. Slightly flexible and more durable. Printing is slightly tricky (requires higher temperatures, slower) and usually has a slight shine. Ideal for high-impact components such as weightlifting, hammer triggers, complex mechanisms or parts exposed to friction.

- ABS/ASA: Provides higher thermal resistance and toughness, but requires closed printers and careful environmental control due to smoke and warping. Can be used for parts near high friction areas, but are usually overkill. ASA has better UV resistance.

- TPU (Flexible): It is crucial to create custom bumpers, soft landing areas, silent catchers or gaskets. Generally, softer lasting times (e.g., shore 85A-95A) are usually sufficient. To add quiet, shocking elements are crucial.

hint: For complex mechanisms involving moving parts, using PETG for gears or levers, while TPU for bushings or dampers can create higher functionality.

-

Design (or choose) Gravitrax-compatible models:

- Key dimensions: GRAVITRAX relies on precise 1×1 and 1×2 grid connections (approximately 15mm center). Accuracy is not negotiable. With these dimensions relative to these dimensions of the connection nails/holes and tracking width/curvature, your existing parts and double-check STL files.

- Orbital geometry: Seamless marble flow is key. Pay careful attention to start/end height, curve radius and stable banking. Test print small sections. The design must take into account the physical marble diameter.

- Structural integrity: Avoid thin walls and fragile connections. Add strategic reinforcements (ribs, burrs) to thin layers, especially in high structures or mechanisms. The goal is at least 1.2mm (2-3 nozzle widths), but the best load-bearing parts are 1.6-2.0mm.

- Dangling and support: Gravitrax natural construction has curves and slopes. Minimize extreme overhangs in design. When there are inevitable situations such as complex undercuts on the base, make sure the slicer produces effective support. Learn similar techniques "The support of the tree" It can be easier to delete.

- Friction is the enemy: Smooth surface marble rolling is crucial. Optimize layer orientation for optimal finish on track (sand or polish if needed). Consider the slight bend over the edge.

- Using existing designs: Platforms like Thingiverse, Printables, and Cults3D have a large number of Gravitrax designs. always:

- Check the comments for a printability report.

- Verify compatibility claims by comments or images.

- View instructions for the required settings and materials.

-

Optimize your print settings for precision and durability:

- Layer height: 0.15mm -0.20mm provides good balance of detail and strength for most parts. For complex mechanisms, fines (0.12mm) are required, for thicker (0.28mm) for the outsole/support.

- filling: The demand for power determines this:

- 20-30% straight/capacity: Enough to accommodate track segments with minimal load, decorative elements.

- 40-60% cubic/capacity/grid: essential for load-bearing base, structural support, lift mechanism, hammering hitter. Avoid using triangles in large solid areas due to nozzle resistance.

- Perimeter (wall): Crucial! Most of the power comes from the walls. At least 3 periphery (preferably critical load parts 4-5).

- Printing speed: slow down! Accurate printing requires patience. The surrounding 40-60mm/s, which is slightly faster for fillings (60-80mm/s), is a good starting point for PLA/PETG. Balance speed and cooling.

- cool down: Excellent cooling (100% fan after the first layer) is essential for cleaning the overhang and preventing the sagging curve, especially on track segments. Ensure optimized printer cooling.

- Bed adhesion: Carefully tied! Models using edges with smaller footprints or ABS/ASA. A simple glue stick or hairspray does a miracle for PLA/PETG on a PEI spring steel plate.

- Nozzle temperature: Follow your advice Specific Filament brand, not universal range. Make a temperature tower for new rolls. Sometimes printing pla is hotter (e.g. 215c) can improve layer adhesion, but be careful to string.

- withdraw: Retract precisely, especially on PETG.

- Perfect basic post-processing:

- Support removal: Use the rinsing cutting machine and needle nose forceps with caution. Slow sand to remove small pieces. Soaking PETG/PLA can greatly reduce the hard support when the side cutter looks risky.

- Grinding and smoothing: Gradually use wet/dry sandpaper to operate smoothly, gradually sand critical contact points (runway, connection nails/holes).

- Functional check: Strictly test new parts. First print a small part. Check marble flow rate, connection safety and mechanism operation. Prepare for iteration – Print, test, adjust the design, reprint! This is the prototype cycle.

- Lubrication (seldom used!): The mechanism by which dry PTFE lubricants are applied to the axle or pivot can enhance movement if Friction after polishing is a problem. Avoid wetting lubricants attracting dirt. Do not apply to marble tracks.

Take Gravitrax to the next level: When plastics need metal

While FDM/resin printing is great on most custom Gravitrax parts, sometimes your ambitions need more. Imagine:

- Super exquisite complex lift mechanism: Requires smooth, reliable weight lifting under load, requires complex gears or high resistance bearings.

- High Clothes Components: Parts that experience constant frictional effects, such as professional rotors or extensions.

- Unique functional art: Elevator taxis, decorative elements or large structural foundations with exquisite metal finishes.

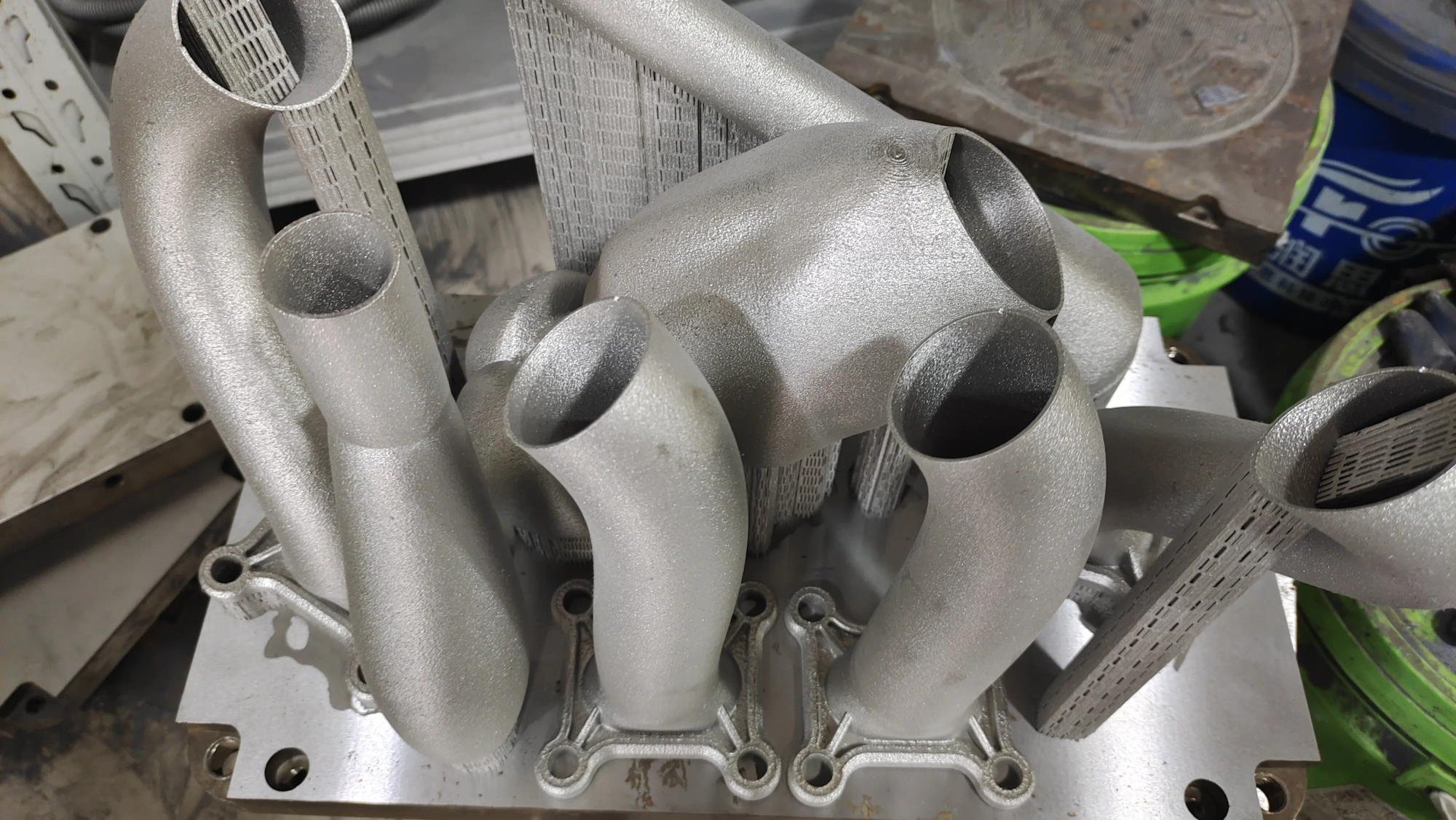

This is Professional metal 3D printing service intervention. enter Great: Your partner’s high performance prototype.

As a leader in rapid prototyping, Great Take advantage of the latest Selective laser melting (SLM) technology. SLM uses a high-power laser to accurately fuse fine metal powders to construct completely dense complex metal parts directly from digital designs. Why is this related to the ambitious Gravitrax creator?

- Unrivaled precision and complexity: SLM can produce complex geometry and internal functions through machining, ideal for optimizing gravity-driven mechanisms or creating visually stunning elements.

- Excellent substance: Print with high strength aluminum, stainless steel, titanium, etc. Choose the ideal metal for increased strength, weight, wear resistance or just aesthetics.

- Professional post-processing: Greglight is not only about printing. They offer a comprehensive finishing service – demolition expert support, precise machining of key features, heat treatment for enhanced characteristics, and amazing finishes (polishing, bead blasting, paint) to lift your custom parts.

- Quick Metal Prototyping: Accelerate your innovation. Greglight focuses on Quick turnaround For custom precision parts, you can iterate faster and integrate complex metal components into Gravitrax masterpieces.

- Solve complex challenges: Their expertise can handle tricky geometry and required functional requirements frontally, turning your ambitious Gravitrax vision into durable metal reality.

Conclusion: Engineering miracle, one layer at a time

3D printing opens up the universe of possibilities for Gravitrax enthusiasts. It transforms the system from a great architectural toy to a powerful platform to learn engineering principles, unleash creativity and solve complex spatial problems. By mastering material selection, design principles, print settings, and post-processing, you can build tracks and mechanisms that ignore your imagination. Start simple, embrace the iterative prototype process, and most importantly, have fun!

Remember the ability of professional metal AM service when your plastic surprise inevitably inspires a vision that requires industrial grade performance and sophistication Great. They are ready to achieve your most ambitious gravity parts with precision and speed.

Ready to revolutionize your Gravitrax build? Explore the world of 3D printing and discover how to bring the most complex metal vision to reality.

Gravitrax 3D Printing FAQ

Q1: Can I print a replacement for the official Gravitrax parts?

Answer: You able Technical modeling and accurate printing of replicas, But respecting intellectual property is important. Avoid distributing exact copies of copyrighted designs. Focus on creating unique custom works, compatible connector non-standard orbital geometry to ethically extend your system.

Q2: What is the best printer for Gravitrax?

A: Any well-calibrated FDM printer can handle Gravitrax parts. Key features of priority: Good dimensional accuracy (Certainly important for connection), Excellent cooling (for drapes and tracks) and a Heating bed For adhesion. Ender 3/V2/Pro/S1 models, PRUSA I3 or BAMBU LABS A1/P1P are popular and capable choices. Resin (SLA/DLP) printers provide amazing details for decorative elements, but are not ideal for large bases or longer flexible tracks due to their brittleness and high cost.

Question 3: Why is my printed track work not properly connected to the official base?

Answer: Because The dimension is inaccurate. reason:

- Printer calibration: Ensure perfect calibration of electronic steps and X/Y/Z steps per millimeter. Print the calibration cube.

- Design Accuracy: Double-check the STL file. The connecting column/hole is measured relative to the formal part (the column with a diameter of ≈4.5mm, the hole interval of 5.0mm is X/Y).

- Material shrinkage: PLA/PETG contracts slightly. Some designers explain this by enlarging the hole/column by 0.1-0.2mm. Test printing is essential.

- Z height problem: Check the bed and exit Z. A slight elephant’s feet can hinder the connection.

Question 4: My marble has poor flow on my printing tracks. Why?

Answer: Possible reasons:

- Surface roughness: If the use is too rough, increase the cooling and layer height. Print printing defects.

- Geometric problems: Check that the curve radiii does not distort (for example, overhanging and sagging) during printing. Make sure the slope is consistent and properly preserved.

- Layer direction: Try repositioning the model so that the track surface is printed as close to the vertical direction as possible.

- friction: PLA/PETG has more friction than molded plastics. Polish or Very small Using a dry PTFE lubricant (test on scrap!) can help – be careful to avoid collecting dust.

Question 5: When should I consider a professional service like Greatlime in the Gravitrax part?

A: Consider professional metal AM services when needed:

- Excellent accuracy of complex mechanics (gears, bearings).

- Plastics allow much higher strength or wear resistance.

- Unique aesthetic properties that can be achieved through metal (polished steel, anode aluminum).

- Large, complex structural bases require high stiffness.

- Develop a mechanism under realistic stress loads before committing to expensive injection mold tools.

Question 6: How do I make sure my custom mechanism prints reliably?

one: Focus on design Printability: Avoid long and thin shafts; use thicker shafts and bearings/bushings. The design gap is slightly larger than the minimum FDM (0.4-0.5mm). Where possible, use a sacrificial interface or snapshot connector instead of a fragile hinge. Print the PET of the gear/lever instead of the brittle PLA. prototype Iteration – Print a simple version first to test the functionality. Great Prototyping expertise can also iteratively quickly test complex multipart mechanisms.