ISO 9001 Factory

ISO 9001 Factory

The world’s first CNC machining center that dares to provide free samples!

Find the maximum extents of plastic and metal materials available for CNC milled and turned parts.

✅ Ideal for low- to medium-complexity prototyping and low-volume production

✅ Prototype design and mass production within 3-5 days.

✅ Low cost and short delivery time are unparalleled advantages.

✅ Great Light CNC Machining ISO 9001 Certified Factory.

✅ ±0.001mm and above precision requirements can be processed.

|

CNC Milling Material

|

GreatLight Maximum Extents

|

Maximum Extents of Other Companies

|

| ABS | 4000*400*150mm, Diameter 500mm | Max. Depth: 3.75 in. (95.25mm) |

| ABS Flame Retardant | 4000*400*150mm, Diameter 500mm | Max. Depth: 1.75 in. (44.45mm) |

| Aluminum 6061-T651 | 4000*400*150mm, Diameter 500mm | Max. Depth: 3.75 in. (95.25mm) |

| Aluminum 7075-T651 | 4000*400*150mm, Diameter 500mm | Max. Depth: 3.75 in. (95.25mm) |

| Brass 260 | 4000*400*150mm, Diameter 500mm | Max. Depth: 1.75 in. (44.45mm) |

| Copper C101 | 4000*400*150mm, Diameter 500mm | Max. Depth: 2.75 in. (69.85mm) |

| CPVC | 4000*400*150mm, Diameter 500mm | Max. Depth: 2.75 in. (69.85mm) |

| HDPE | 4000*400*150mm, Diameter 500mm | Max. Depth: 3.75 in. (95.25mm) |

| LDPE | 4000*400*150mm, Diameter 500mm | Max. Depth: 0.75 in. (19mm) |

| Low Carbon Steel CR 1018 | 4000*400*150mm, Diameter 500mm | Max. Depth: 1.25 in. (31.75mm) |

| PA Nylon 6 | 4000*400*150mm, Diameter 500mm | Max. Depth: 3.75 in. (95.25mm) |

| PA Nylon 6/6 | 4000*400*150mm, Diameter 500mm | Max. Depth: 2.75 in. (69.85mm) |

| PA Nylon 6/6 (30% GF) | 4000*400*150mm, Diameter 500mm | Max. Depth: 0.75 in. (19mm) |

| Polycarbonate (Black) | 4000*400*150mm, Diameter 500mm | Max. Depth: 1.75 in. (44.45mm) |

| Polycarbonate (Clear) | 4000*400*150mm, Diameter 500mm | Max. Depth: 1.75 in. (44.45mm) |

| Polycarbonate (Translucent) | 4000*400*150mm, Diameter 500mm | Max. Depth: 1.75 in. (44.45mm) |

| Polycarbonate (20% GF) | 4000*400*150mm, Diameter 500mm | Max. Depth: 3.75 in. (95.25mm) |

| PEEK | 4000*400*150mm, Diameter 500mm | Max. Depth: 1.75 in. (44.45mm) |

| PEI Ultem 1000 | 4000*400*150mm, Diameter 500mm | Max. Depth: 1.75 in. (44.45mm) |

| PEI Ultem 2300 (30% glass-filled) | 4000*400*150mm, Diameter 500mm | Max. Depth: 2.75 in. (69.85mm) |

| PET | 4000*400*150mm, Diameter 500mm | Max. Depth: 1.75 in. (44.45mm) |

| PMMA (Acrylic) | 4000*400*150mm, Diameter 500mm | Max. Depth: 2.75 in. (69.85mm) |

| POM Acetal Homopolymer (Delrin 150) | 4000*400*150mm, Diameter 500mm | Max. Depth: 2.75 in. (69.85mm) |

| POM Acetal 20% Glass filled (Delrin 570) | 4000*400*150mm, Diameter 500mm | Max. Depth: 3.75 in. (95.25mm) |

| POM Acetal Copolymer | 4000*400*150mm, Diameter 500mm | Max. Depth: 1.75 in. (44.45mm) |

| POM Acetal Static Dissipative (Tecaform SD) | 4000*400*150mm, Diameter 500mm | Max. Depth: 3.75 in. (95.25mm) |

| PP (Polypropylene Homopolymer) | 4000*400*150mm, Diameter 500mm | Max. Depth: 2.75 in. (69.85mm) |

| PP (Polypropylene Copolymer) | 4000*400*150mm, Diameter 500mm | Max. Depth: 2.75 in. (69.85mm) |

| PPE/PS (Noryl 265) | 4000*400*150mm, Diameter 500mm | Max. Depth: 3.75 in. (95.25mm) |

| PPSU (Radel R 5500) | 4000*400*150mm, Diameter 500mm | Max. Depth: 1.75 in. (44.45mm) |

| Polystyrene (PS) | 4000*400*150mm, Diameter 500mm | Max. Depth: 1.75 in. (44.45mm) |

| Polysulfone (PSU) | 4000*400*150mm, Diameter 500mm | Max. Depth: 1.75 in. (44.45mm) |

| PTFE (Teflon) | 4000*400*150mm, Diameter 500mm | Max. Depth: 2.75 in. (69.85mm) |

| PVC | 4000*400*150mm, Diameter 500mm | Max. Depth: 3.75 in. (95.25mm) |

| Stainless Steel 17-4 PH | 4000*400*150mm, Diameter 500mm | Max. Depth: 1.75 in. (44.45mm) |

| Stainless Steel 304/304L | 4000*400*150mm, Diameter 500mm | Max. Depth: 1.75 in. (44.45mm) |

| Stainless Steel 316/316L | 4000*400*150mm, Diameter 500mm | Max. Depth: 1.75 in. (44.45mm) |

| Steel Alloy 4140 | 4000*400*150mm, Diameter 500mm | Max. Depth: 1.75 in. (44.45mm) |

| Titanium Ti 6-4 | 4000*400*150mm, Diameter 500mm | Max. Depth: 1.75 in. (44.45mm) |

| UHMW | 4000*400*150mm, Diameter 500mm | Max. Depth: 3.75 in. (95.25mm) |

| Get A Quote | Learn more |

|

CNC Turning Material

|

GreatLight Maximum Extents

|

Maximum Extents of Other Companies

|

| Aluminum 6061-T651 | 4000*400*150mm, Diameter 500mm | Max. Diameter: 3.95 in. (100mm) |

| Aluminum 7075-T651 | 4000*400*150mm, Diameter 500mm | Max. Diameter: 3.95 in. (100mm) |

| Brass C360 | 4000*400*150mm, Diameter 500mm | Max. Diameter: 3.95 in. (100mm) |

| Low Carbon Steel CR 1018 | 4000*400*150mm, Diameter 500mm | Max. Diameter: 2.95 in. (75mm) |

| Stainless Steel 17-4 PH | 4000*400*150mm, Diameter 500mm | Max. Diameter: 2.95 in. (75mm) |

| Stainless Steel 304/304L | 4000*400*150mm, Diameter 500mm | Max. Diameter: 2.95 in. (75mm) |

| Stainless Steel 316/316L | 4000*400*150mm, Diameter 500mm | Max. Diameter: 2.95 in. (75mm) |

| Steel Alloy 4140 | 4000*400*150mm, Diameter 500mm | Max. Diameter: 2.95 in. (75mm) |

| Titanium Ti 6-4 | 4000*400*150mm, Diameter 500mm | Max. Diameter: 2.95 in. (75mm) |

| Get A Quote | Learn more |

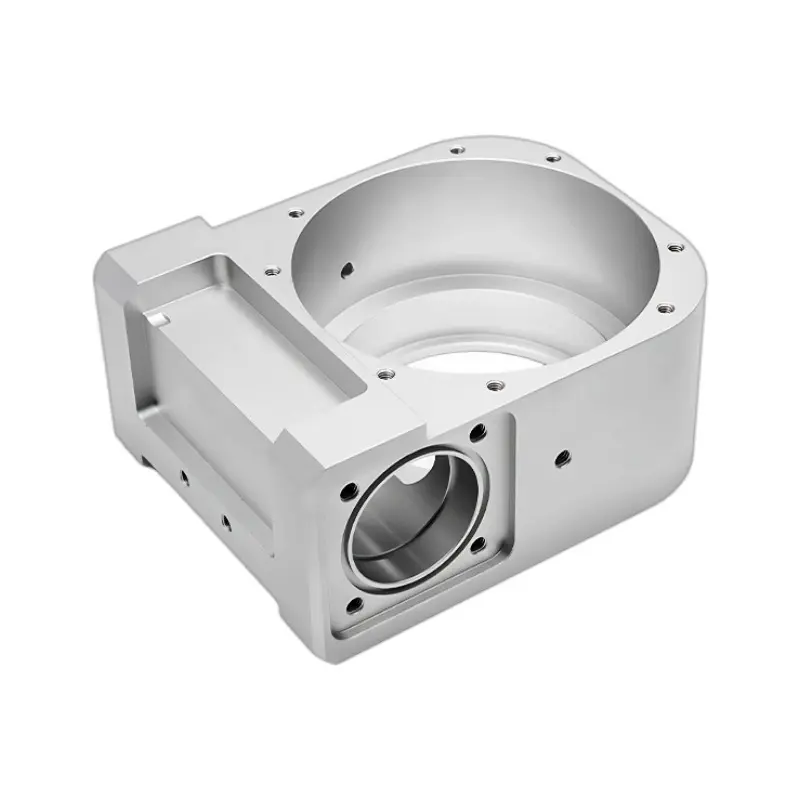

We use CNC to quickly process small and large-volume production orders for clients in a variety of industries: industrial design, automotive parts, robotic parts, prototypes, medical devices, aerospace, defense, electronics, hardware startups, industrial automation, machinery, marine, and more.

There is no limit on the order quantity and product value.

There are many types of materials for CNC processing. The main metal materials are: aluminum alloy, stainless steel, brass, various steels, titanium alloys, etc., which can meet the performance requirements of different materials.

One of the most important advantages of CNC prototypes is that its CNC processing accuracy is higher than other processing, and the maximum tolerance can reach ±0.001mm / 0.001 In, and multi-faceted structural products can be formed in one go.

CNC prototypes have high fidelity and high surface treatment level. After subsequent processing such as grinding, polishing, sandblasting, painting, silk screen, UV, electroplating, etc., the product effect is completely comparable to the products produced by the mold.

With years of manufacturing know-how, Great Light has covered you for CNC Machining and low-volume manufacturing.

Achieve the perfect finish with our range of surface treatments. Whether you require anodizing, plating, or painting, we ensure your parts meet both aesthetic and functional specifications.