Unlocking Pet Care Innovation: The Ultimate Guide to 3D Printed Dog Bowls

For pet owners looking for a truly personalized feeding solution, 3D printed dog bowls represent the cutting edge of customization, functionality and design. This technology goes beyond generic plastic or ceramic options, allowing you to customize the bowl to your dog’s unique needs—whether that’s to accommodate a specific breed’s anatomy, address health concerns, or simply showcase your style. As pioneers in metal additive manufacturing, we’ll explore how advanced processes offer unparalleled advantages to discerning pet lovers.

Why consider 3D printing your dog’s bowl?

Traditional bowls often fall short. They may be unstable, difficult to clean, harbor bacteria easily, or be too bland. 3D printing solves these problems by:

- Precise customization: Design the perfect size bowl for your Toy Poodle or Great Dane, with the ideal depth and width for your nose shape or eating habits.

- Enhancements: Integrated ergonomic ramps for easier access to the neck, non-slip bases tailored to your flooring or integrated section dividers. For pets with arthritis or limited mobility, the ergonomic elevated design can reduce stress.

- Health and Hygiene: Choose biocompatible materials that are inherently nonporous, resistant to bacterial growth, and easier to disinfect—crucial for sensitive pets.

- Unparalleled uniqueness: Engraving names, intricate patterns, or custom shapes not possible with traditional manufacturing. Create heirloom quality pieces that reflect your personality.

Designing the perfect bowl: key considerations

- Dimensions and volume: Accurately calculates capacity based on breed size, meal portions and water needs. Avoid bowls that are too small or too large, which can lead to mess or dehydration.

- Shape and Ergonomics:

- Elevated Design: Reduces neck/joint stress (ideal for seniors or giant breeds).

- Contoured Base: Sloped interior facilitates easier access to food and thorough cleaning.

- Stability: The wide, textured base prevents slipping, perfect for naughty or enthusiastic eaters. Custom weights can be integrated.

- Material selection: This decision will have profound consequences for safety, durability and maintenance.

- Personalization: Fonts, logos, portraits, bas-reliefs – express your personality.

Choosing the right material: Beyond plastic

While plastics (PLA, PETG) offer economics and color for basic non-metallic printers, Metal 3D printing takes pet bowls to a high-end levelespecially using Selective Laser Melting (SLM) technology:

- Stainless steel (316L): The gold standard. Non-toxic, extremely durable, corrosion-resistant, dishwasher safe and bacteriostatic. Great for everyday use.

- titanium: Ultra-light, hypoallergenic and incredibly strong. Great for travel bowls or highly active pets.

- Aluminum alloy: Lighter than steel, has excellent cooling/heating capabilities, thermal conductivity (depending on design), good corrosion resistance.

| Compare: | feature | SLM Metal (Stainless Steel/Titanium) | FDM plastic (PLA/PETG) | ceramic products |

|---|---|---|---|---|

| Durability | extremely high | ease | fragile | |

| health | Best (no errors; easy to sanitize) | Good (easily scratched) | Porous (can accommodate bacteria) | |

| Heat/freeze resistance | Excellent | Low (warpage) | Excellent | |

| Custom details | very high | medium | Low (before ignition) | |

| weight | medium/variable | Light | heavy | |

| ecological impact | Highly recyclable | Variables (bio vs petroleum) | If it doesn’t break, it will last. |

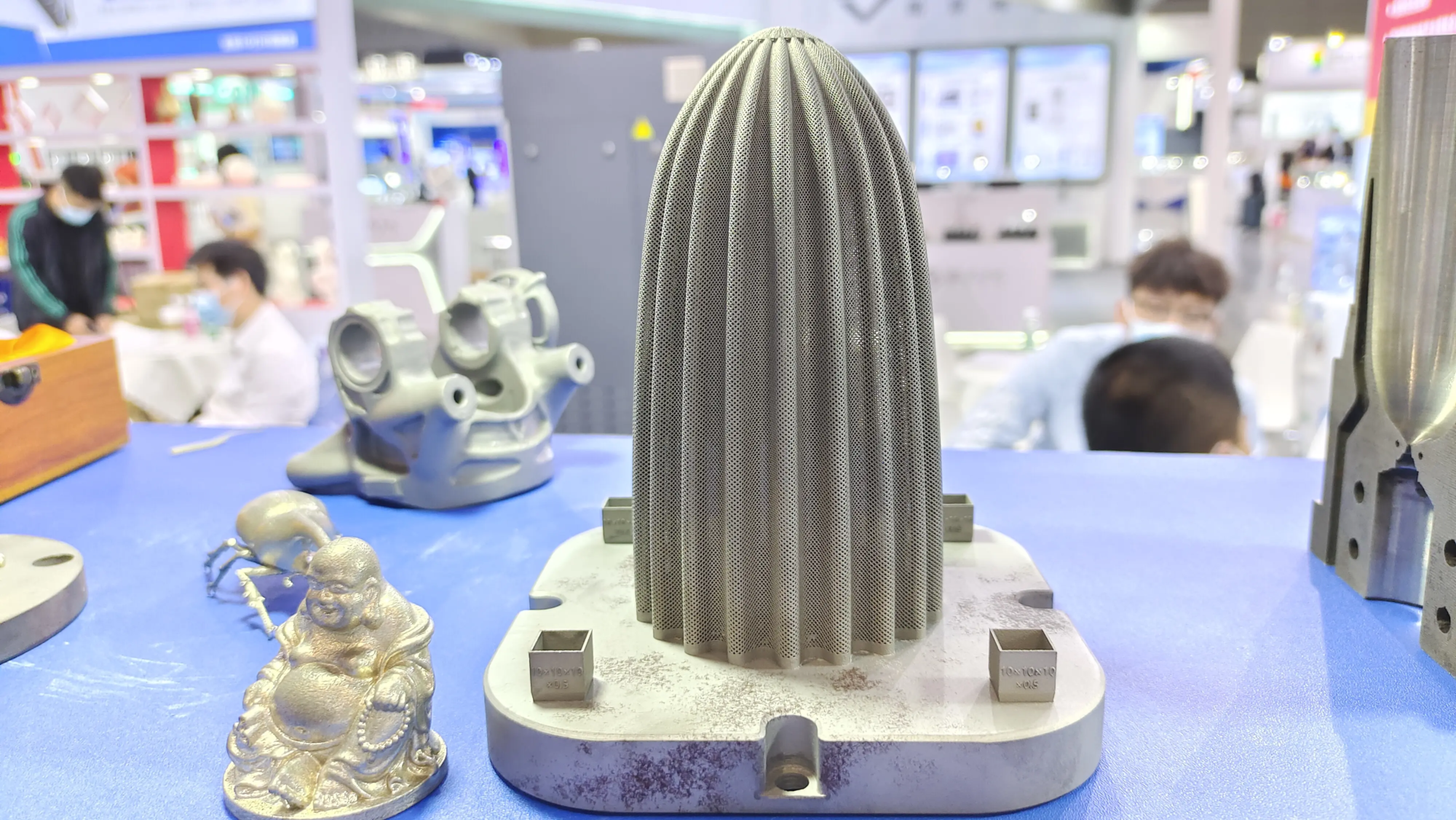

SLM 3D printing advantages: precision and strength

Selective Laser Marking (SLM)GreatLight specializes in technology that uses high-power lasers to fuse fine metal powders layer by layer. For dog bowls, this means:

- Complex geometric shapes made simple: Create internal channels for integrated cooling/heating (check with a professional to ensure safety), intricate textures, or a seamless weighted base that requires no assembly.

- Unparalleled Structural Integrity: The density of the parts is close to that of a solid, and its strength is comparable to that of traditional forged metals. The bowl can withstand gnawing, drops, and everyday wear and tear.

- Excellent surface details: Achieve precise engraving, smooth curves or matte/textured finishes directly from the printer bed. Minimal supports reduce post-processing requirements.

- Material efficiency: Near net shape production minimizes waste compared to machining solid blocks.

Safety First: Keep Your Pets Healthy

Metal printing reduces common risks:

- Chemical Safety: SLM.sleepers are made from medical-grade alloy certified for biocompatibility (ISO 10993). No BPA, phthalates or harmful polymer additives.

- Non-porous surface: Eliminates microscopic pockets where bacteria can thrive. Highly smooth polished metal finishes are easiest to clean.

- Structural reliability: Eliminate weak points in thin walls prone to cracks or sharp edges from aging plastic. Metal resists chewing damage better.

- Easy sterilization: Boil, run in the dishwasher, or chemically sterilize metal bowls without degrading—crucial for pets prone to allergies or who are immunocompromised.

Post-processing: for perfection and hygiene

The original print needs improvement, especially for food contact:

- Key Finishes: The fine-grain surface polish removes microscopic pores where bacteria hide, leaving a smooth, pleasant feel.

- Special coating: Food-safe sealants or non-toxic PVD coatings (e.g. gold, rose gold, bronze) enhance aesthetics and corrosion resistance.

- Ultrasonic cleaning: Complete removal of residual powder ensures metallurgical purity.

- Quality control: Rigorous inspection of structural soundness and surface integrity. Look for a supplier like GreatLight that specializes in food contact approvals.

Professional finishing transforms functional prints into show-worthy pet essentials.

Ordering a Custom Metal Dog Bowl: The GreatLight Process

- conceptualization: Define key requirements – size, functionality, material preference, aesthetics.

- design: Share sketches or requests. Our engineers will convert them into optimized CAD files. Consider ergonomics and veterinary recommendations.

- Material selection: Choose from stainless steel (the most popular), titanium or aluminum depending on your needs/budget.

- Prototyping: Receive prototypes (depending on complexity) for functional testing before full production.

- Production: Parts are printed with SLM, stress-relieved heat treated, meticulously cleaned, and finished to your specifications (polished, coated, engraved).

- Final inspection and delivery: Guaranteed dimensional accuracy and high-quality surface, complying with food safety standards.

Transform mealtimes from ordinary to extraordinary. Whether it’s a titanium travel bowl with Danish monograms or a custom-cooled stainless steel fountain design, GreatLight’s expertise in metal prototyping connects imagination to reality. With advanced SLM equipment and comprehensive finishing capabilities, we efficiently solve complex manufacturing challenges.

Conclusion: The future of pet dining is personalized

3D printed dog bowls go beyond simple feeding purposes. They represent a fusion of advanced manufacturing, thoughtful pet care and personal expression. Metal printing, especially via SLM, offers unparalleled durability, hygiene and design freedom, making it ideal for creating truly customized solutions to support years of health and happiness. While plastic bowls may suit simpler needs, investing in a professionally made metal bowl ensures safety, longevity, and lasting value. Embrace innovation tailored for your best friends.

FAQ: Answers to 3D Printed Dog Bowl Questions

Q: Are 3D printed metal bowls safe for my dog?

one: Of course, when professionally produced using biocompatible metal alloys such as 316L stainless steel or titanium and finished to food grade standards. Choose a reputable manufacturer that prioritizes roughness levels and rigorous cleaning.

Q: How to clean a 3D printed metal dog bowl?

one: Metal bowls are low maintenance: they can be washed by hand or in the dishwasher. Sterilization cycles are acceptable. Avoid using abrasive pads to prevent surface scratches.

Pope: If my dog chews a titanium bowl, are there more risks?

Sleep: Stainless steel and titanium are both extremely hard alloys. While they are not indestructible, they are more resistant to chewing damage than plastic or ceramic. There are no additional risks compared to traditional metal bowls.

Q: How durable are metal 3D printed bowls compared to cups?

one: Properly printed (SLM) metal parts have density characteristics comparable to cast/machined parts. When used with care, expect a lifespan of over ten years – protected from chipping, cracking or UV deterioration.

Q: What factors affect the cost of custom bowls?

one: Complex geometries, material grade (high quality titanium), metal weight, detail complexity (deep engraving), level of finishing (mirror polish/PVD coating), ceramics.

Q: Can you make colorful metal bowls?

one: A colorless PVD coating applied after printing produces a tint similar to Gun-oriented gold nitride.

Q: How much does my stainless steel bowl weigh?

one: Approximately 30% thinner walls enable lightweighting yet remain rigid. GreatLight engineers optimize the weight-to-strength ratio based on specific needs specifications.

Q: Is customization limited compared to plastic?

one: Complex designs requiring complex supports can often be successfully handled with plastics; metal printing pushes the boundaries in different ways, enabling integrated functionality, standardized plastic substance stability limits, premium features such as heat sinks, integrated cooling channels, sealed chambers, and possibly metal.

Enhance your pet’s experience: GreatLight utilizes cutting-edge SLM 3D printers and deep expertise to turn your unique dog bowl vision into reality. We handle complex metal prototyping—from custom sizes and specialty features to comprehensive finishing—while ensuring food contact safety and top-notch craftsmanship. Whether it’s a one-off heirloom or a small batch, you can elevate your daily feeding routine. Contact GreatLight today to discuss making your design usable!