Taking Nature to New Levels: The Ultimate Guide to 3D Printed Hanging Planters

Hanging planters have revolutionized indoor and outdoor gardening, blending aesthetics with space efficiency. But what if you could create a truly unique planter based on your style, space, and plant needs? Enter 3D printinga technology that transforms digital designs into functional art. For the hobbyist, designer, or commercial grower, this guide explores how 3D printing can bring endless possibilities to hanging planters using cutting-edge manufacturing technology.

Why choose 3D printed hanging flower pots?

Traditional flower pots limit creativity. Via 3D printing:

- Customization is king: Design geometric patterns, organic shapes or brand-specific patterns.

- space optimization: Create vertical gardens for apartments, balconies or urban environments.

- Iterate quickly: Prototype and refine designs in hours instead of weeks.

- sustainable development: Use recycled filament or optimize material usage to reduce waste.

Functional and beautiful design

Success depends on the balance of aesthetics and practicality:

-

structural integrity:

- weight distribution: Make sure support points (such as hooks) can support soil, water and plants. Use simulation software to test stress points.

- wall thickness: 1.5–3 mm minimum to ensure durability. Thicker walls (5mm+) are suitable for heavy metal printing.

- drape: Avoid designs that require unsupported overhang >45°. Use arches or internal supports.

-

Drainage and aeration:

- Integrated holes in the base (3-5 mm diameter) and side vents to prevent root rot.

- hint: Add removable drip tray (printed separately) for indoor use.

-

Material compatibility:

- People’s Liberation Army (Biodegradable): Best for indoor use. Avoid prolonged exposure to UV rays.

- PETG/ASA: UV resistant, suitable for outdoor environments.

- TPU rubber: Flexible design such as clip hook.

- Metal (stainless steel/titanium): Ideal for heavyweight, high-end designs. GreatLight’s SLM printers achieve this through corrosion-resistant alloys.

- Assembly and installation:

- Modular connectors simplify multi-seeder systems.

- Incorporate a carabiner-like clip into the design for easy hanging.

Materials and Technology: From PLA to Metal

Plastic printer (FDM/SLA):

- frequency division multiplexing: Affordable for home users. Use waterproof filament, such as PETG.

- SLA: Higher resolution, rendering intricate details.

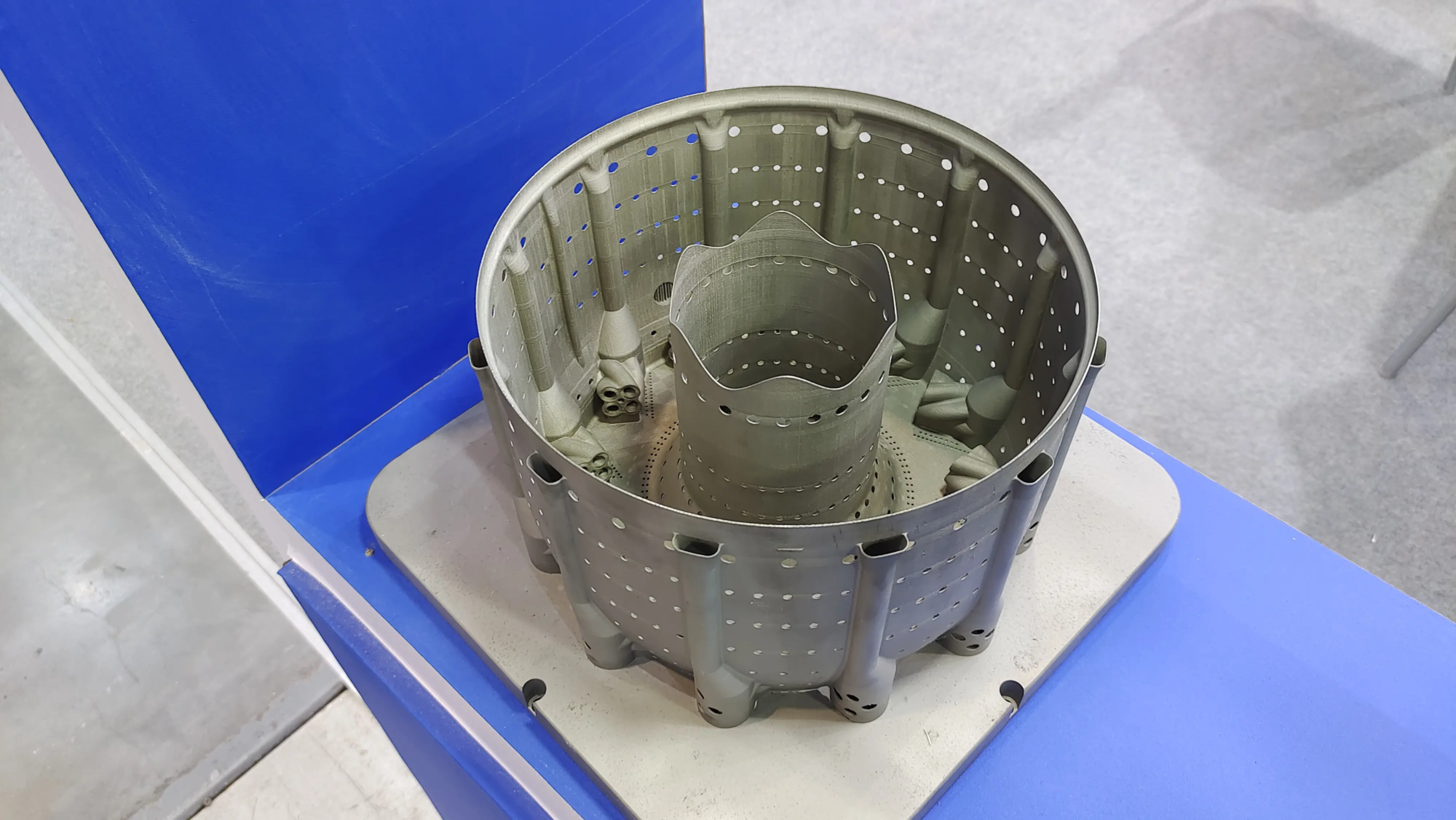

Metal 3D printing (SLM):

- Perfect for high quality, durable flower pots. GreatLight’s Industrial SLM Printers Precisely produce strong, lightweight metal structures.

- benefit: Weatherproof, fireproof, superior structure, suitable for large cantilever designs.

- example: Titanium flower pots with a lattice pattern that can only be achieved through additive manufacturing.

Post-processing: Improves aesthetics and durability

Original prints need refinement to shine:

- Sanding/Smoothing: Removes layer lines for shine. Acetone vapor (for ABS) or polish (for PLA).

- water proof: Coat epoxy resin on PLA print for moisture resistance.

- metal surface treatment: Glow Offer Professional post-processing:

- polished/matte finish

- color powder coating

- Anti-corrosion treatment

- assembly: Bond parts with a waterproof adhesive such as marine epoxy.

Advantages over traditional manufacturing

- Cost-effective prototyping: Inexpensively test designs before mass production.

- complex geometric shapes:Create internal irrigation channels or integrate hangers.

- Scalability: Print in one go or in batches with negligible setup costs.

- ecological awareness: Minimize waste by adding methods compared to subtracting methods.

Step-by-step creation guide

- design: Use Fusion 360 or Tinkercad. Inset hanger slots and drainage.

- Slicing and optimizing:Adjust filling density (20–40% for plastic, 10–20% for metal).

- Print:

- PLA: 190–220°C nozzle, 60°C bed.

- Metal (via GreatLight): SLM technology, layer height 30–60μm.

- Post-processing: Sanded, sealed and assembled.

- Mountain: Secure with moisture-proof hooks.

Case Study: Sustainable Vertical Gardens

A coffee shop we have worked with huge light Create hanging planters from recycled stainless steel powder. SLM printing enables lightweight hexagonal modules that can be interlocked into the green walls, using 60% less material than CNC milling.

in conclusion

3D printed hanging planters blend innovation and gardening to help everyone from hobbyists to architects. Whether printed at home in durable plastic or professionally crafted using industrial metal SLM technology such as GreatLight’s solutions, these planters offer unparalleled customization, sustainability and functionality. As urban gardening evolves, utilizing rapid prototyping can ensure your design is not only beautiful, but also visionary.

Explore your vision with GreatLight

Ready to prototype your metal hanging planter? huge light Combines advanced SLM 3D printing, precision post-processing and rapid prototyping expertise to bring your most complex designs to reality. Request a quote for metal planters that blend elegance with engineering!

FAQ: 3D printed hanging flower pots

Q: Are 3D printed flower pots safe for plants?

A: Yes, if designed properly. Use non-toxic filaments (PLA, PETG) or inert metals. Always include drainage and plastic coating to prevent moisture degradation.

Q: Can I print hanging planters at home?

Answer: Of course! FDM printers work well with PETG or PLA. Start with a smaller design (<15 cm) to avoid distortion.

Q: How long can 3D printed flower pots be used outdoors?

A: PLA degrades under UV light; use UV-resistant ASA or PETG. Metal prints (stainless steel, titanium) thrive outdoors indefinitely.

Q: Why choose metal 3D printed flower pots?

A: For superior durability and design freedom. GreatLight’s SLM technology creates rust-proof, load-optimized structures not possible with traditional methods.

Q: How are plastic flowerpots waterproof?

A: Seal with a layer of epoxy or marine varnish, focusing on the interior surfaces.

Q: What is the cost range for professional metal printing?

A: Varies by size, material and finish. GreatLight offers competitive pricing for rapid prototyping – submit your design for an accurate quote.

Q: Can I print flower pots from recycled plastic?

Answer: Yes! Recycled PET filament works well. To enable sustainable metal printing, GreatLight uses recyclable powders such as reprocessed titanium.

Start building your green innovation today—where nature meets next-generation design! 🌿✨