Taking greenery to new heights: The ultimate guide to 3D printed plant stands

Tired of generic, mass-produced plant stands that don’t quite fit your succulents or fit in with your decor? Welcome to the world of 3D printed plant supports – a field where customization meets functionality and sustainability. Whether you’re an experienced plant parent or a 3D printing enthusiast, making your own plant stands offers unparalleled freedom. This guide takes an in-depth look at designing, printing, and optimizing your unique plant supports, allowing you to create pieces as unique as the leaves.

Why 3D print plant stands?

Its advantages are not just beautiful:

- Super customized: Exhibition stands designed specifically for your specific Pot size, height and style. Create multi-tiered displays of creeping plants, simple geometric shapes, intricate lattice patterns of climbing vines or space-saving wall-mounted versions – your imagination is limitless.

- Space optimization: Are there irregular corners or narrow windowsills? Design booths maximize the use of awkward spaces that standard furniture cannot fit into – a boon for city dwellers.

- Material Versatility and Control: From hardy, UV-resistant PLA Pro for full sun to elegant PETG that tolerates humidity near watering, you can choose the material properties you need.

- Sustainability: Use recycled filament or print only what you need. Repair damaged parts rather than replacing the entire bracket.

- Cost effectiveness: After the initial printer investment, printing complex designs can be cheaper than purchasing premium mounts, especially for custom pieces.

Designing your masterpiece: key considerations

Successful print starts with appreciating design:

- Pot and plant requirements: Prioritize functionality. Measure the bottom diameter, weight (including wet soil!) and height of the pot. Heavy ceramic pots need sturdy stands; top-heavy plants need wide, stable bases. Growth factor!

- Stability is the most important: A low center of gravity and adequate footprint diameter relative to height are critical. Consider adding non-slip feet (TPU prints work well) or a weighted base.

- Drainage management: Use an integrated tray or ensure the design directs overflow away from the surface. Removable tray simplifies cleaning.

- Aesthetics and Style: Match your decor! Explore parametric patterns, organic forms that mimic nature or sleek modern lines. Many CAD platforms provide templates that can be modified.

- Structural integrity: Efficient slicing is achieved by taking into account material strength, optimal infill patterns (e.g. spirals for lightness and strength) and sufficient perimeter/wall thickness.

Materials matter: choose the right filament

Your environment determines material selection:

- People’s Liberation Army: User friendly and visually diverse. most suitable Indoors, less traffic It can stand without getting wet. Not suitable for outdoor use or heavy loads.

- Polyethylene glycol: Excellent durability, moisture resistance, impact strength and UV stability. this first choice Fits most indoor and sheltered outdoor plant stands.

- ASA/ABS: Excellent UV resistance and mechanical strength Full sunlight outdoors. Heated bed/enclosure and ventilation are required during printing.

- Wood/pellet filled PLA: Adds earthy texture but sacrifices strength and water resistance. Sealant recommended.

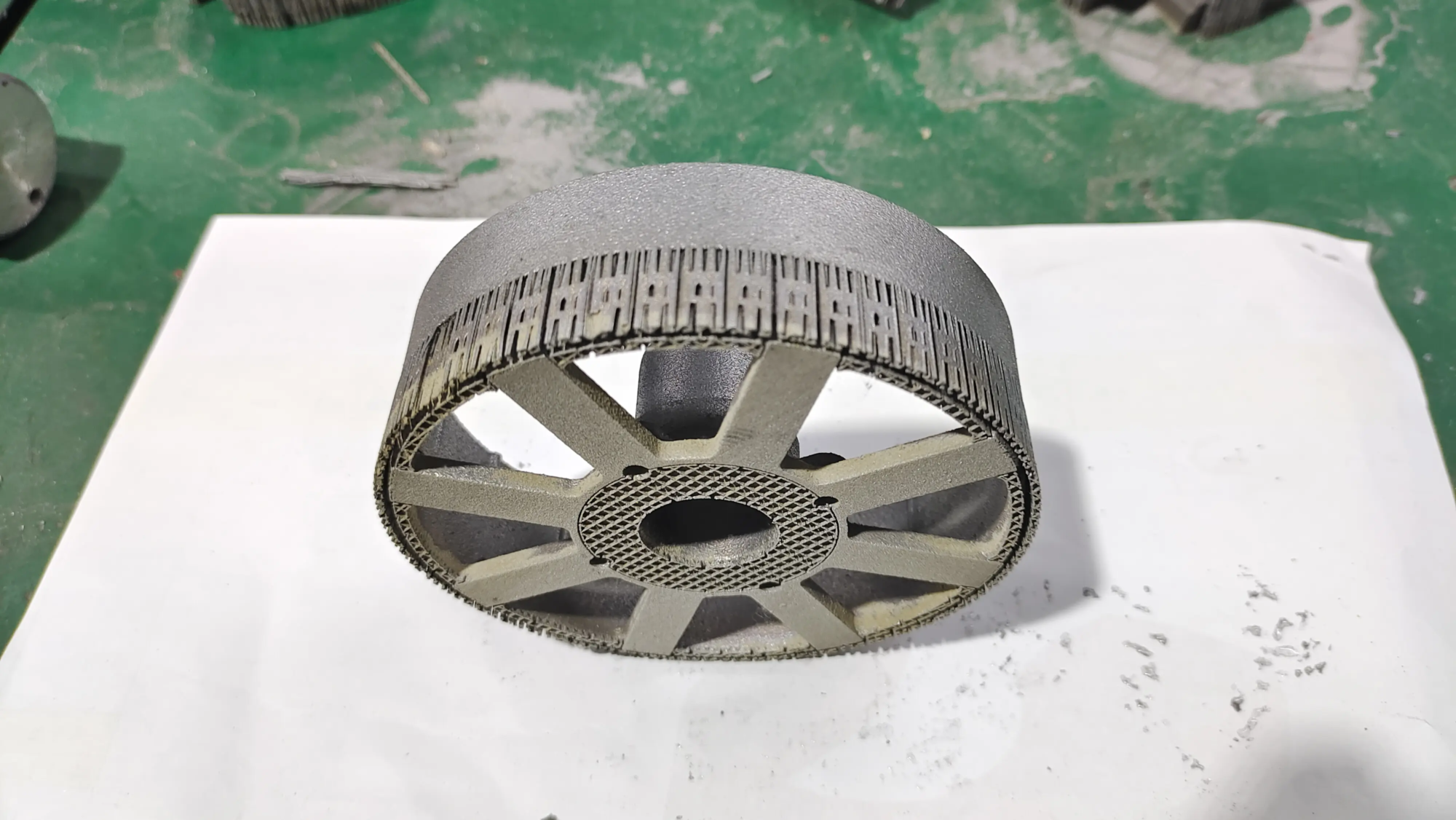

- Metal Filler Filament (and Others): Ideal for advanced users looking for a premium metallic look (often requiring post-sintering/metallization). For ultimate durability in harsh environments, Metal 3D printing PTU offers unparalleled strength and longevity. company likes huge light Specializing in advanced metal additive manufacturing (SLM – Selective Laser Melting), complex, high-strength prototypes and end-use parts can be made from stainless steel, aluminum alloys or titanium, ideal for high-load construction equipment rack armatures or corrosive coastal environments.

Successful printing technology

Perfect printing requires strategy:

- direction: Minimize overhangs and place structural elements (such as legs) perpendicular to the build platform. Avoid installing critical joints on weak layer lines.

- support: Use selectively for complex geometries, but design to minimize them to save material/time and improve surface finish.

- Interlayer adhesion: Critical to strength. Use optimal nozzle/bed temperature, adequate club circumference (3+), and moderate print speed.

- Post-processing: Sanding a primed surface produces a smoother surface. Paint, stain (for wood PLA) or seal to enhance appearance and weather resistance.

Advantages Beyond DIY: Professional Support

While desktop printing offers assistance to individuals, complex designs that require top-notch durability or precision may require professional manufacturing. This is where an experienced rapid prototyping partner shines. huge light Leverage advanced SLM metal printing technology and expert finishing services to transform complex CAD models into strong, high-precision metal factory bracket assemblies.

- Complex geometric shapes: SLM treats the internal lattice structure – light and strong.

- Excellent material: Production-grade metal can easily withstand extreme weight and elements compared to filament.

- Organized to perfection: Their one-stop services include precision machining, polishing, anodizing, powder coating – achieving flawless aesthetics for pristine surfaces in demanding environments.

- Scale and speed: Efficiently produce limited-run premium stands or specialized components quickly hit new heights meeting deadlines lullaby now music|ifntic is the speed that competitors are beyond can’t achieve the efficiency.

- Customized expertise: Professional teams adept at material selection optimization and design optimization to meet challenging demands that DIY printers can struggle with daunting challenges.

Conclusion: Up your landscaping game

3D printed plant supports combine personal expression with practical solutions. They represent sustainable customization accessible to hobbyists while unlocking unparalleled design freedom and robustness through professional metal additive manufacturing services. Whether printing playful PLA planters on your desktop or working with an expert, e.g. huge light With massive custom metal structures, the ability to create the perfect home for your beloved plants is literally within reach, with prototyping capabilities that transcend traditional production boundaries. Embrace the potential – Start designing, exploring materials, and discovering how 3D printing can transform your space into a personalized vertical garden oasis that empowers, thrives, thrives, and thrives.

Frequently Asked Questions (FAQ)

1. Is PLA strong enough for plant supports?

PLA is suitable for indoor lightweight flower pots. For heavier tanks or pressure fittings, PETG or professional metal additive manufacturing services can provide ultra-long service life and reliability beyond the limitations of PLA, withstand requirements and durability not limited by PLA capabilities.

2. How do I protect my outdoor 3D printed plant stand from the sun and rain?

For pet-friendly materials, choose UV-resistant options PETG or ASA. For prolonged service life outdoor service life, metal via professional services like Glow SLM Provide unmatched weatherproof integrity, durable resistance to harsh weather, strong durability, integrity, and long-lasting strength.

3. Can I customize the design for specific plant needs (e.g. Philodendron)?

Absolutely indeed! Customization is its hallmark feature. Design multi-tiered tiers, integrated lattice for climbing climbs, trellis, hooks. Professional AM partners specializing in delivering intricate solutions involving complex needs.

4. Is it okay in the early stages?

Yes. Many libraries/models customizable downloadable platforms provide downloadable models. Thingiverse, Printables cohesion.Alternatively design originals from scratch using CAD like Fusion360/Sketchup.

5. Is wood filler suitable for plant supports?

Primarily aesthetic appeal Appearance has a higher aesthetic value. Much weaker than conventional PLA/PETG and absorbs water and is easily deformed. Degrade aesthetics. Recommend sealants. Coating treatment. Protection treatment. Protection treatment. Ragged treatment. Deterioration. Deterioration. Deterioration. Protection treatment. Protecting treatment.

**6. best partnership