The Ultimate Guide to 3D Printing Airsoft Guns: Innovation at Your Fingertips

The airsoft hobby is growing rapidly, and 3D printing is revolutionizing the way players customize, repair and create unique replicas. This fusion of additive manufacturing and airsoft offers unprecedented freedom, but requires careful consideration of technology, materials, safety and legality. This guide explores everything enthusiasts need to know about 3D printed airsoft guns, turning concepts into high-performance reality.

Why Choose 3D Printed Airsoft Guns?

3D printing enables players to overcome limitations:

- custom made: Uniquely designed grips, stocks, rail systems or entire receivers based on ergonomics or aesthetics.

- Rare parts replicas: Resurrection of vintage replica components that have been discontinued and cannot be used commercially.

- Prototyping: Quickly iterate on transmission housing prototypes before investing in expensive injection molds.

- Lightweight: Create optimized structures not possible with subtractive manufacturing.

Choosing the right 3D printing technology

Not all printing processes are suitable for the demanding applications of airguns:

-

Fused Deposition Modeling (FDM):

- advantage: The most convenient, low-cost printer/consumable; suitable for gun stocks, grips, decorative parts, clamps.

- shortcoming: Weak interlayer adhesion; anisotropic strength; lower accuracy/surface finish compared to alternatives.

- Best for: Prototyping of non-stressed parts and functional parts.

-

Stereolithography (SLA/LCD/DLP):

- advantage: Excellent detail resolution; smooth surface finish; isotropic nature.

- shortcoming: Resins are often brittle; UV degradation issues; post-processing required.

- Best for: Complex internals (triggers, selectors), sights, detailed external components.

-

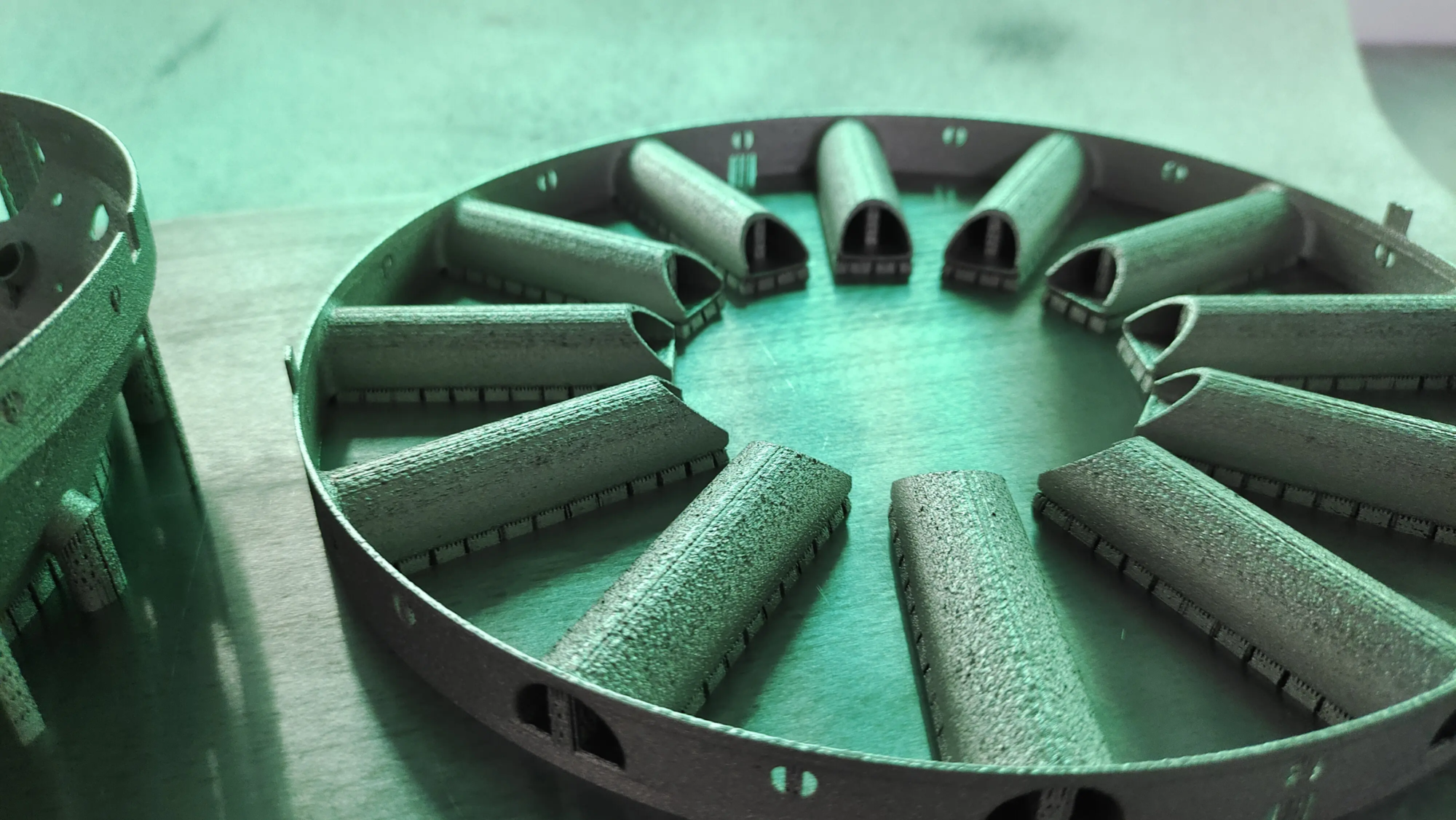

Selective Laser Sintering (SLS) and Multi-Jet Melting (MJF):

- advantage: Uses nylon powder for excellent strength/toughness; isotropic; requires no support structure; very durable.

- shortcoming: Higher cost; less access via consumer printers (mainly industrial/service bureaus).

- Best for: Highly stressed functional parts (gearbox housing, reinforced receiver, trigger assembly).

- Metal Additive Manufacturing (SLM/DMLS):

- advantage: Unparalleled strength, heat resistance and durability; creates fully dense metal parts.

- shortcoming: Significantly more costly; requires specialized industrial equipment/expertise.

- Best for: Critical high-load components (transmission housing, cylinder head, piston head, nozzle internals).

Material Matters: Choosing Filament and Powder

- People’s Liberation Army: Easy to print, but fragile and heat sensitive. Avoid use in functionally stressed parts.

- ABS: Tougher and better heat resistant than PLA. Heated bed/enclosure required. Warp layer bonding problems are prone to occur.

- Polyethylene glycol: Impact resistant, good interlayer adhesion, UV/chemical resistant. Excellent balance of many functional peripherals.

- Nylon (PA6, PA12 – filament/powder): The gold standard in printed airgun durability (especially SLS/MJF). Excellent impact resistance, fatigue life and toughness. Easily absorbs moisture.

- Reinforced composite materials (CF, GF nylon): Significantly improves stiffness, strength and creep resistance. Highly abrasive – requires hardening of printer nozzles.

- Engineering resin (tough, durable, high temperature resistant): SLA resin is superior to FDM plastic in toughness and detail, but requires careful UV protection.

- Metal (AlSi10Mg, stainless steel 316L, titanium): Ideal for mission-critical, ultra-durable components requiring true metal mechanical properties.

Design and Engineering: Beyond STL Files

Successful airsoft printing relies on smart design:

- CAD proficiency: Mastery of CAD software (Fusion 360, SolidWorks) is non-negotiable for functional parts.

- Stress analysis: Simulate force (FEA) or strategically orient prints to maximize strength. The layer line is the weakest point.

- Wall thickness and filling: Balance strength and weight. Walls that are too thin will crack; too much infill wastes time/material without proportionally increasing strength (aim for 40-70% for functional parts).

- Tolerances and fits: Consider shrinkage/warping. Suitable for design clearance fit of moving parts (0.2-0.5mm)